FOR FIGHTING OIL FIRES.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

Brief Details of a Machine Purchased by an Important Oil Company.

METE PIGHTING of oil fires is a 1 problem beset with many difficulties, and if extensive damage is to be prevented it is essential that effective means of combating the spread of a fire be brought into use with the least possible delay. All those concerned with the handling of oil are aware of this fact, and most of the prominent oil companieS take, adequate precautions to meet contingencies which may arise in this directi on.

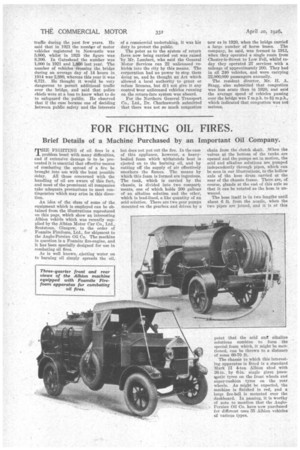

An idea of the class of some of the equipment which is employed can be obtained from the illustrations reproduced on this page, which show an interesting Albion vehicle which was recently supplied by the Albion Motor Car Co., Ltd., Seotstoun, Glasgow, to the order of Foamite Pirefoara, Ltd., for shipment to the Anglo-Persian Oil Co. The machine in question is a Foamite fire-engine, and it has been specially designed for use in combating oil fires.

As is well known, ejecting water on to burning oil simply spreads the oil,

but does not put out the fire. In the case of this appliance, however, a heavybodied foam which withstands heat is ejected on to the burning oil, and by cutting off the supply of air effectively smothers the flames. The means by which this foam is formed are ingenious. The tank, Which is carried by the chassis, is divided into two compart7 ments, one of which holds 200 gallons of an alkaline solution and the other, which is lead-lined, a like quantity of an acid solution. There are two gear pumps mounted on the gearbox and driven by a chain from the clutch shaft. When the valves at the bottom of the tanks are opened and the pumps set in motion, the acid and alkaline solutions are pumped independently through pipes, which can be seen in our illustrations, to the hollow axle of the hose drum carried at the rear of the chassis frame. There are, of course, glands at the end of this axle so that it can be rotated as the hose is unwound.

The hose itself is-in two lengths until about 6 ft. from the nozzle, when the two pipes are joined, and it is at this