Burrell's New Steam Wagon.

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

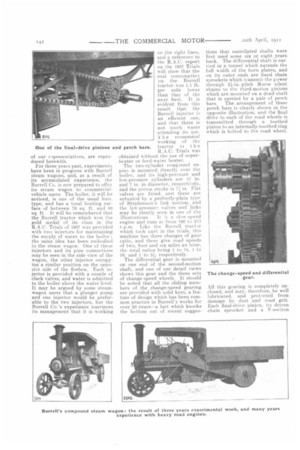

A Vehicle with Many Practical Features ; Produced by the Makers of the Tractor which Won the R.A.C. Gold Medal in the Commercial Vehicle Trials of 1907.

If one pauses to consider which of the various types of steam wagons that were offered to the public some 10 years ago have survived the test of practical application, one is forced to the conclusion that the lines advocated by traction-engine builders in the early days of the motor movement have proved to be the best. True, there are one or two successful exceptions from the traction type of wagon, bat they only represent a very-small percentage of the large number of types which were offered to the public in the early days of the heavy-motorcar movement. Realizing that most of the early Lypcs were doomed to failure, some oldestablished traction-engine builders decided to postoone the design and construction of any traction-type wagons in their own works until users had had amole opportunity to test, and, in most cases, to break up in service, many of the weird models which lumbered along our roads 10 and more years ago.

One of these manufacturers ir; Charles Burrell and Sons, Ltd., of the St. Nicholas Works, Thetford, which company was established in the year 1770, and was the first to produce a combined threshing and dressing machine, which machine was exhibited in 181S at the Royal Agricultural Society's Show, at York, and there earned the Society's prize medal. The records of the company's trading show that in 1871 and 1872 it was building high-speed road engines, whilst some 20 years earlier what was probably the first " pedrail " was produced in its works ; the original mounted drawings of that machine yellowed with age, now hang upon the walls of the company's drawing office. The Governments of Russia, France, Turkey, Peru, Venezuela, and Hungary, and the Viceroy of Egypt are but a few of the important customers for which Burrell machines have been erected, and the Burrell tractors and engines which were used during the South African War, by the Royal Engineers and the I lectrical Engineers Volunteers, won high praise for their maker.

A distinctive feature of all Burrell road engines is the provision of a separate pair of final-drive spur gears for each of the driven road

wheels. By this method of construction, the weight of the unsprung parts may be made very low in proportion to the power of the motor, and, consequently, a higher speed may be obtained, and maintained, without the risk of excessive damage to the working parts. The advantages of this method of transmission have proved to be more marked on Burrell tractors than on larger engines. It is not surprising, therefore, that the same type of transmission has been adopted for this company's new steam wagon, several detail views of which, specially taken at the works by one

of our i ±,presentatives, are reproduced herewith.

For three years past, experiments have been in progress with Burrell steam wagons, and, as a result of its accumulated experience, the Burrell Co. is now prepared to offer its steam wagon to commercialvehicle users. The boiler, it will be noticed, is one of the usual loco. type, and has a total heating surface of between 70 sq. ft. and 80 sq. ft. It will be remembered that the Burrell tractor which won the gold medal of its class in the R.A.C. Trials of 1907 was provided with two injectors for maintaining the supply of water to the boiler ; the swim idea has been embodied in the steam wagon. One of these injectors and its pine connections may be seen in the side view of the wagon, the other injector occupying a similar position on the opposite side of the firebox. Each injector is provided with a couple of clack valves, and water is admitted to the boiler above the water level. It may be argued by some steamwagon users that a plunger pump and one injector would be preferable to the two injectors, but the Burrell Co.'s experience convinces its management that it is working

on the right lines, and a reference to the R.A.C. report on the 1907 Trials will show that the coal consumptioe on the Burrell tractor was 1.1 lb. per mile lower than that of the next best. It is evident from this result that the Burrell injector is an efficient one, and that there is not much waste attending its use.

h e economical working of the tractor in t h e R.A.C. Trials was obtained without the use of superheater or feed-water heater.

The two-cylinder compound engine is mounted directly over the boiler, and its high-pressure and low-pressure cylinders are 4,!:

and 7 in. in diameter, respectively, and the piston stroke is 7 in. Flat valves are fitted, and these are actuated by a perfectly-plain type of Stephenson's link motion, and the low-pressure valves and links may be clearly seen in one of the illustrations. It is a slow-speed engine and runs at from 190 to 210 r.p.m. Like the Burrell tractor which took part in the trials, this machine has three changes of gear ratio, and these give road speeds of two, four and six miles an hour, the total ratios being 1 to IS, 1 to 10, and 1 to :5 respectively. The differential gear is mounted on one end of the second-motion shaft, and one of our detail views shows this gear and the three sets of change-speed wheels. It should be noted that all the sliding members of the change-speed gearing are provided with solid keys, a feature of design which has been common practice in Burrell's works for over 20 years—a fact which knocks the bottom out of recent sugges

pinions and perch bars. tions that castellated shafts were first used some six or eight years back. The differential shaft is carried in a tunnel which extends the full width of the horn plates, and on its outer ends are fixed chain sprockets which transmit the power through 2i-in.-pitch Morse silent chains to the third-motion pinions which are mounted on a dead shaft that is carried by a pair of perch bars. The arrangement of these perch bars is clearly shown in the opposite illustration, and the final drive to each of the road wheels is transmitted through a toothed pinion to an internally-toothed ring which is bolted to the road wheel.

All this gearing is completely enclosed, and may, therefore, be well lubricated, and protected from damage by dust and road grit. Each final-drive pinion, its driven chain sprocket and a V-section brake drum are securely bolted together and ride freely on the ends of the dead third-motion shaft, which, as already stated, is carried by a couple of cast-steel perch bars. These perch bars are provided with simple means of adjustment for tightening the chain.

One's first impression of the main frame is that its members are too light in section, but a reference to the rear view of the chassis will show that, in addition to the 5-in. channel steel side members, there

are deep flitch plates about in. thick and 12 in. deep. These flitch plates are securely bolted to the side channels, and their forward ends are secured to extensions from the horn plates of the boiler. This

method of construction ensures a very rigid frame without its appearing unduly cumbersome. The back axle is fixed, and is forged from a billet of steel. its centre portion is of square section, while the ends are, of course, turned down to take the ends of the perch bars, the spring saddles and the

rear-wheel naves. The perch bars are fairly close together, and from the centre of the axle a springmoun to ti drawbar is anchored, so tha t When a trailer is in use the load is taken by the axle.

The standard size of the rear wheels fitted to Burrell wagons is 4 ft. in diameter ; these give a platform height of 4 ft. 6 in. from the ground, but wheels 3 ft. 6 in in diameter may be fitted ifdesired, although the company wisely prefers, and recommends, the fitting of

the larger size. In external appear

ance, they resemble disc wheels, but the view reproduced on page 141 shows that they are not of that. type. They are of cast steel with eight spokes each ; stamped-steel discs are secured on the outside faces of these spokes so as to protect the gears, and similar discs, which are carried by the perch bars, cover the inner faces of the wheels._ In order to eliminate the d rumpling sound, which would otherwise be very pronounced, wooden blocks are introduced between the east-steel spokes and the outer steel discs. In addition to the final-drive pinion brakes to which we have already referred, the usual Burrell flywheel brake is fitted, these constituting the two systems demanded by the Heavy Motor Car Order.

In conclusion, we must record our representative's appreciation of the orderly arrangement of every department of the St. Nicholas works, and the general cleanliness which there prevails. It is not often that one sees machine tools kept in spiek and span condition, machined parts kept bright, trays and beds clear of accumulations of shavings, shop floors regularly and frequently swept, each part laid out on the floor so that it may be seen and not buried beneath a mass of other pieces, and a hundred and one other instances of tidiness, which convince the visitor that the management takes a pride in both works and workmen. We have often heard the assertion made that such a state of affairs can only be maintained during " slack " periods. Burrell's shops are always like that, and they rarely know what it means to be " slack." No doubt Mr. W. Campbell Wilson's early training at sea has much to do with his insistance upon so orderly a state_