A Belt and Pulley Change-speed Unit for Machine Tools

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

Pt our issue dated December 17, 1943, we described a change-speed unit employing V-pulleys and a belt, the chief feature of which was that a change of ratio could be effected without the need for bringing the pulleys to rest, It has, too, the added advantage of quiet running as compared with a normal type of gearbox.

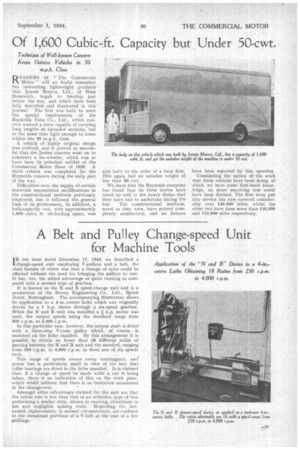

It is known as the N and B speed-change unit and is a production of the Newey Engineering Co., Ltd„ Brook Street, Nottingham. The accompanying illustration shows its application to a 4-in.-centre lathe which was originally driven by a 1 h.p. motor through a six-speed gearbox. When the N and B unit was installed a h.p. motor was used, the output speeds being -the standard range from 500 r.p.m. to 2,000 r.p.m. In this particular case, however, the output shaft is fitted with a three-step V-cone pulley which, of course, is matched on the lathe mandrel. By this arrangement it is possible to obtain no fewer than 18 different ratios of gearing between the N and B unit and the mandrel, ranging from 250 r.p.m. to 4,000 r.p.m. in three sets of six speeds each.

This range of speeds covers every contingency, and' power lost is particularly small in view of the fact that roller bearings are fitted to the lathe mandrel. It-is claimed that, if a change of speed be made while a cut is being taken, there is no indication of this on the work piece, which would indicate that there is no hesitation occasioned in the change-over. • Amongst other advantages claimed for the unit are that the initial cost is less than that of an orthodox type a box performing a similar duty, silence in running, cleanliness in use and negligible upkeep costs. Regarding the lastnamed, replacements, in normal circumstances, are confined to the occasional purchase of a V-belt at the cost of a few shillings.