PLANNING THE LAYOUT THE HAULIER'S GARAGE

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

THE present is hardly the time for building new garages; in fact, permission to engage in any such enterprise would, I imagine, be most difficult to obtain. Many operators, however, seem to think that it is opportune for giving consideration to the subject in preparation for afterthe-war developments. I hear a lot of talk about it, and I have received a number of inquiries relating to garage layout and equipment.

The subject is certainly an interesting one. Moreover, it affords me an opportunity to impart additional variety to these articles without in any way detracting from their usefulness.

I am not going to concern myself with dimensions which, after all, are determined by the size of the fleet for which the garage is required: I am going to consider principles and disposition of equipment, etc., leaving the operator to expand or contract the premises according to his needs and the number of vehicles for which he wishes to cater. I propose to do so by way of example rather than precept. In its simplest form a garage is just a shed in which to house the vehicles and, when they are not in use, to protect them from the elements. In practice, that conception is immediately seen to fall short of the barest needs; as the operator at once sees that there. must be some provision for fuelling and oiling the vehicles, also for washing them. It is a moot point whether, even in the simplest form of garage, there should not be provision for heating the premises during the winter, not only to obviate the risk of damage as the result of frost, but to ensure easy starting on cold mornings.

Premises on the above lines would he satisfactory if there were a motor agent within a short distance of the garage, who could be relied upqn to carry out all the service operations required as and when it was convenient for the haulier to have those operations performed.

A Method Which Wastes Time and Fuel Even in those rare instances where there is such a motor agent, it is seldom, indeed, that his premises are so near that it does not shortly become apparent to the haulier that a good deal of time and petrol are wasted in running backwards and forwards to the agent to have certain routine maintenance operations carried out.

I have known cases where premises have been laid out on the lines mentioned, and then, a little while after, the haulier has decided that he had better install equipment to enable him to carry out pressure greasing, brake adjustments and -provide for minor attention to carburetter, sparking plugs, injectors, and so on.

As a matter of fact, those motor agents in this country who are alive to the needs of the commercial-vehicle operator in general and the haulier in particular, and who are willing to provide such service as is requisite, which in normal times caHs for 24 hrs. per day, are few indeed. In consequence, there 'was, before the war, a growing tendency for operators to make provision to carry out repairs on their own premises, and to provide equipment to that end.

That tendency is growing, and an increasing number of hauliers was and still is putting in up-to-date equipment for repairs and maintenance. The longer the motor trade takes to make up its mind to deal with this problem energetically and in a thorough and comprehensive manner, the more difficult will it be for members of that industry to be able to capture the custom of heavy-vehicle operators.

A significant pointer in this matter is the way in which quite small concerns have appreciated the value of unit replacement schemes and have seized on the advantages which such schemes afford. The man with only three vehicles, provided they are of the same make and type, finds it worth while to have a spare engine. One operating six vehicles will have a couple of spare engines, spare units, and quite a considerable provision of stores and spare parts. Such an operator will put his repair department in charge of a really capable mechanic, and one not afraid of hard work. He will pay him a really good wage, enough to ensure that the man will value his job and will be willing to go to any reasonable lengths to give satisfaction so that he does not lose it. Such a man soon realizes that the last thing be can be is a clock watcher, and that his busiest time, in all probability, will come when other people have gone home for the day. He usually does not mind that at all, and is an enthusiast for his work. He is satisfied, and so is the operator, because he knows his fleet is always likely to be in being.

With fleets of more than six vehicles it was rapidly becoming the rule for hauliers to make full and complete provision for repairs, including major overhauls, carrying out every operation with the possible exception of crankshaft grinding; there are not a few who even include that amongst the jobs which they are capable of doing in their own establishments.

In answer to those who suggest that-.parsimony . and unwillingness to -pay a good price for a good job are at the bottom of this tendency, I can tell them that nothing is farther from the truth. Wages paid are, in the majority of cases, about" the levels which prevail in those premises which cater only for repairs. The object which the opetator has in view, that which has compelled him to go to alt this trouble, is that of having the work done immediately, and at any time of the day or night, so that his vehicles are not kept off the road during working hours or, if they must be off the road, then for as shorta time as pOssible.

The illustrations which accompany this article indicate what operators have found to be preferable arrangements Of premises and plant and the amount and type of equipment which they have discovered to be needed in order to keep their fleets in a state of preparedness for work.

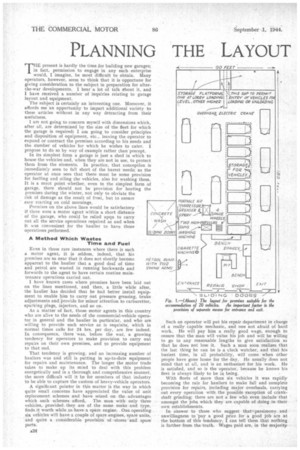

Figs I and 2 relate to a garage to accommodate about 20 vehicles. The first essential which I would like to establish as being applicable to any garage, irrespective of the number of vehicles, is that there should be separate provision for entrance and exit. In this case, this need has been interpreted to the fullest extent by fitting up the whole of one end of the premises with sliding doors so that ingress and egress are possible anywhere along the whole face of the building.

Normally, as is indicated, one set of doors is used as an entrance and the other as an exit. In between these, the sliding doors give access to the repair shop, as shown. This arrangement of entrance and exit has the further advantage that• the vehicles can be conveniently stored and yet can leave in any order, without inconvenience or the need to move any vehicle which is not so early on the rota of service for that day.'

The Position of Fuel-supply • Pumps is of Importance

Two more features to which reference may be made as indicating essential requirements are the location of the petrol and oil fuel pumps near the entrance so that vehicles can be fuelled as they enter after having finished a day s work and, secondly, the location of the wash outside the building. As each vehicle is fuelled a record is made of the quantities taken and the speedometer readings, as recorded, thus affording a running check on fuel consumption. Included in the equipment is a high-pressure washing plant with two .guns, which to-day is regarded as an essential piece of garage equipment.

A feature of the repair shop is the arrangement ,of the pit, which is well shown in Fig. 2. It should be noted that, whilst it is, in effect, a double pit, one is much shorter than the other. There is a good reason for this. The long leg of the pit conforms to the usual plan. With such a pit it is possible to work on the under-side of the vehicle from end to end. Often, however, it happens that not only. is there no need to work in that way, but it is preferable to have a good floor level under one part of the vehicle whilst the other is over the pit.

Take a couple of examples to illustrate this. The engine may be having a top overhaul while the back axle is receiving attention; only the latter operation, as a rule, necessitates a pit. Alternatively, the engine sump may be dropped over the pit while the rear-brake shoes are being changed.

The bench and vice are down on the floor level of the pits, so that there is no need for the fitter or mechanic to climb stairs every time he wants to take a part to the bench. The interior of the pit is equipped with bulkhead lights and with points for plugging in electric-tool leads. The walls are painted white, and there is a fall in the floor level with natural drainage The equipment includes a 'portable air compressor and pressure greaser, together with an injector-testing and repair plant, electric welding equipment and battery-charging facilities.. This operator is in the habit of storing goods in transit, and it is to facilitate this that one end of the garage, as shown, is fitted up as a loading, unloading and sorting platform. .

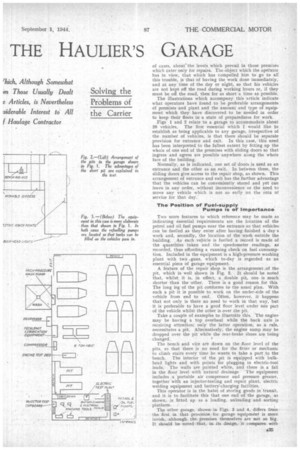

The other garage, shown in Figs. 3 and 4, differs from the first in that provision for garage equipment is more lavish, although the premises themselves are not so big. It should be noted .that, in its dersign, 'it compares with the preliminary essentials which I outlined in describing the first garage, in that it has entrance and exit doors, pumps at the entrance, and an outside wash.

The repair shop, in this case, is in one corner. Besides machine tools, the equipment includes a universal electric

testing outfit, a battery-charger, repair equipment for ett.ctrca I components, injector test-cupboard, welding plant and a comprehensive collection of small tools, there being one set for each mechanic, which he keeps in his own locked box.

Steps in one corner 'of the repair shop lead down to the floor level of the pits, which are just outside the repair she's, but, of course, inside the repair Premises. For convenience, when working on a vehicle a line of benches is provided on the floor level of the pits.

The engine test-bed shown is not provided with h.p. measuring equipment. It is utilized for running-in engines after they have been overhauled, end for carrying out tests of individual cornpe In this case, the greasing equipment is one of the most modern Tecalemit types, and faces a 6-ton hoist capable of lifting the largest vehicle owned by the operator.

Again, it should be noted that a high-pressure washing plant i provided, and a compressor with pipe lines running all around the garage. These premises are heated by a hot-water system, the range of pipes traversing the premises. An unusual feature is the placing of the degreasing plant

which, like the wash, is outside the building, making, presumably, for cleanliness indoors. Over the workshop, and extending over -the pit, is an upper story, as shown in

Fig. 4. Part of this is utilized as offices and part as stores.

S.T.R.