MORE LOAD LESS COST

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

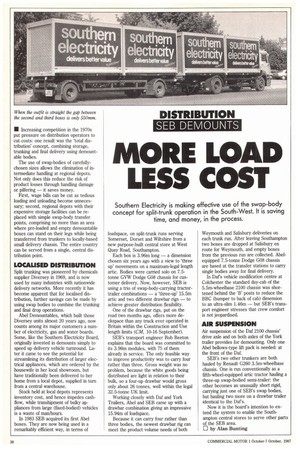

Southern Electricity is making effective use of the swap-body concept for split-trunk operation in the South-West. It is saving time, and money, in the process.

• Increasing competition in the 1970s put pressure on distribution operators to cut costs: one result was the 'total distribution' concept, combining storage, trunking and final delivery using demountable bodies.

The use of swap-bodies of carefullychosen sizes allows the elimination of intermediate handling at regional depots. Not only does this reduce the risk of product losses through handling damage or pilfering — it saves money.

First, wage bills can be cut as tedious loading and unloading become unnecessary: second, regional depots with their expensive storage facilities can be replaced with simple swap-body transfer points, comprising no more than an area where pre-loaded and empty demountable boxes can stand on their legs while being transferred from trunkers to locally-based small delivery chassis. The entire country can be served from a single, central distribution point.

LOCALISED DISTIUBUTION

Split trunking was pioneered by chemicals supplier Diversey in 1969, and is now used by many industries with nationwide delivery networks_ More recently it has become apparent that for localised distribution, further savings can be made by using swap bodies to combine the trunking and final drop operations.

Abel Demountables, which built those Diversey units almost 20 years ago, now counts among its major customers a number of electricity, gas and water boards. Some, like the Southern Electricity Board, originally invested in demounts simply to speed up delivery vehicle turnround. Later it came to see the potential for streamlining its distribution of larger electrical appliances, which are ordered by the housewife in her local showroom, but have traditionally been delivered to her home from a local depot, supplied in turn from a central warehouse.

Stock held at local depots represents inventory cost, and hence impedes cashflow, while transhipment of bulky appliances from large (fixed-bodied) vehicles is a waste of man/hours.

In 1983 SEB acquired its first Abel boxes. They are now being used in a remarkably efficient way, in terms of loadspace, on split-trunk runs serving Somerset, Dorset and Wiltshire from a new purpose-built central store at West Quay Road, Southampton.

Each box is 3.96m long — a dimension chosen six years ago with a view to 'three up' movements on a maximum-legal length artic. Bodies were carried solo on 7.5tonne GVW Dodge 008 chassis for customer delivery. Now, however, SEB is using a trio of swap-body-carrying tractortrailer combinations — a 'three-up' 15.5m artic and two different drawbar rigs — to achieve greater distribution flexibility.

One of the drawbar rigs, put on the road two months ago, offers more de&space than any truck ever operated in Britain within the Construction and Use length limits (CM, 10-16 September).

SEB's transport engineer Bob Beeton explains that the board was committed to its 3.96m modules, with 75 of them already in service. The only feasible way to improve productivity was to carry four rather than three. Gross weight was no problem, because the white goods being distributed are light in relation to their bulk, so a four-up drawbar would gross only about 26 tonnes, well within the legal 32.5-tonne UK limit.

Working closely with Dal and York Trailers, Abel and SEB came up with a drawbar combination giving an impressive 15.94m of loadspace.

Because it can carry four rather than three bodies, the newest drawbar rig can meet the product volume needs of both Weymouth and Salisbury deliveries on each trunk run. After leaving Southampton two boxes are dropped at Salisbury en route for Weymouth, and empty boxes from the previous run are collected, Abelequipped 7.5-tonne Dodge 008 chassis are based at the transfer stations to carry single bodies away for final delivery.

In Dots vehicle modification centre at Colchester the standard day-cab of the 5.5m-wheelbase 2100 chassis was shortened behind the 'B' posts to reduce the BBC (bumper to back of cab) dimension to an ultra-slim 1.46m — but SEB's transport engineer stresses that crew comfort is not jeopardised.

AIR SUSPENSION

Air suspension of the Daf 2100 chassis' drive axle and on both axles of the York trailer provides for demounting. Only one Abel bellows-type lift pack is needed: at the front of the Daf.

SEB's two other trunkers are both hauled by Renault G260 3.5m-wheelbase chassis. One is run conventionally as a fifth-wheel-equipped artic tractor hauling a three-up swap-bodied semi-trailer: the other becomes an unusually short rigid, carrying just one of SEB's swap bodies, but hauling two more on a drawbar trailer identical to the Dal s.

Now it is the board's intention to extend the system to enable the Southampton central stores to serve other parts of the SEB area.

0 by Alan Bunting