Trailer men get ahead

Page 76

Page 77

Page 78

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

Continued from page 70

curtain-sided semi-trailer exhibited by Welford Truck Bodies. The all-aluminium chassis is formed from strengthened 1sections which have a minimum of welding to reduce the possibility of fatigue.

The unladen weight of the trailer chassis is 4.1 tonnes (3 tons 19cwt) which gives an excellent payload capability. The only fly in the ointment is the fact that raw aluminium has reached £1,000 per ton with a consequent effect on lightweight trailer prices.

The step-frame Welford trailer is a neat device designed to accommodate standard 1 SO containers while keeping down the overall height where loading heights are critical. It is equipped with a tilt mechanism at the front for easy discharge. Frameless

On show for the first time at Earls Court, Tidd Strongbox is showing two Strongbox 80 chassisless trailer vans. These are available in five basic types with laminate wall construction There has been a marked decline in the sales of the chassis vans in recent years when compared with the chassisless type. As an example of this Crane Fruehauf now reports a proportion of one to 1 MOO for chassis and chassisless sales. The van has now taken over a great deal of the flat platform market as it offers a greater load security and weather protection without the need for roping and sheeting.

At the Show there are a great many "extradevices to be seen on the trailer front. The York stand is a classic example of this with the Hobo lifting axle set up and aerodynamic front panel known as the Air-O-Foil.

The Hobo is one of those devices which has been seen for many years, but has only just appeared on the trailer scene. Why it has I find difficult to understand as the benefits resulting from it (lower rolling resistance, less tyre scrub and increased manouevrability) are obvious.

Many operators have found that the boom in Middle East traffic has not been quite the pot of gold that they were hoping for. With the trailer side the position is somewhat different. The trailer manufacturers are selling their products to Middle East Countries — they are not merely operating them. After weathering the economic storm over the past two years, they deserve to succeed. MANY OPERATORS are faced with reducing capital expenditure and with economising on running costs to • emain viable, but they are all motivated by the need to get the best value for their money.

This has increased the appeal of the long-lasting body as well as, in a variety of cases, the necessity to exploit the benefits of matching the body to particular service requirements, with or without the aid of easy loading devices or a demountable facility..

At the past two shows at Earls Court interest mainly centred on demountable systems, and since 1972 important traffic developments have included the more extensive use of drawbar demountables. Although exhibits this year indicate a continuing importance of demountable developments, the emphasis overall is on lightness and durability, with grp-faced / plywood onepiece construction challenging aluminium and showing promise of large-scale penetration of the market later on.

Other trends include proliferation of curtain-sided and sliding-door bodies, catering for easy pallet loading, and of lightweight tippers on eightwheeled chassis.

Grp-faced/plywood panels can be fabricated to provide the structural strength required for the application and an insulant of appropriate thickness can be readily bonded to a panel, polystyrene or the more efficient and costly polyurethane being currently the materials normally employed by the majority of bodybuilders.

Exhibiting for the first time, the make of Glasonit — Technical Panel Industries Ltd — is displaying a Freightbox SC1DS container, built by Longwell Green Coachworks, which is of the type supplied to Dunlop Semtex for its intermodal road/rail distribution system. The peripheral framing is of extruded aluminium, and it is notable that a number of aluminium companies are producing special extrusions designed to accept this type of panelling.

Upwards of 10 exhibitors at the Show are displaying Glasonit bodies, including the pioneers in the application of the material to road-vehicle bodies, the Tidd Strongbox company which is also a first timer at the Show is exhibiting a semi-trailer dryfreight van and a gas-refrigerated type.

But TPI and Tidd are not having it all their own way in the supply and application of laminate panels; a Coldshield semi-trailer refrigerated van shown by Massey having dawnpress polyurethane-insu lated grp/ply panels, is on view standing alongside a dry-freight box van with Glasonit panels.

A comparative newcomer to the panel-construction industry, Dawnpress Ltd is based at Chapel Street, New Mills, via Stockport, and various types of panel produced by the company have been subjected to impact, flexural, racking and column-loading tests by the Yarsley Testing Laboratories.

While Silverdale Refrigerated Vehicles are known to be users of grp/ply panels, a new Silverdale local-delivery van on a VVV LT is a one-piece grpsandwich type without ply reinforcement. The structure is sufficiently robust to support three layers of alloy shelving on each side, Temperature control is by eutectic hold-over plates.

In the case of an Arlington refrigerated body the insulated grp/ply panels are by Concargo, and the panels provide sufficient strength for hanging meat. Some builders of grp/ply bodies say that use of the material has a significant weight penalty, while others contend that the penalty is negligible, if compared with conventional aluminium construction. The current price of aluminium of £1,000 per tonne would appear to be an important factor in the choice of the material by at least a minority of bodybuilders.

New demountable body systems shown by Dobson, York, Edbro, and Freight Bonallack are of contrasting types covering a wide range of applications.

For example, the Dobson is designed for 7.5-tonne-gvw vehicles and has four rams working together which give an -even-lift,while the Freight Bonallack modified Loadspeeder model has two single

action lifting bridges which provide a "straight-lift."

A second Freight Bonallack system has knee-jointed rearmounted legs which raise the body as the vehicle is moved backwards without auxiliary power.

Two new demounts are also shown by York, the air-powered Airswop and one designed for demounting skip bodies, the latter being designed for mounting on standard 16-ton gvw chassis and having twin hydraulic boom rams.

While the Edbro Rolatip demountable tipper body on the bodybuilder's stand is designed for vehicles of around 4.4m (14ft 6in) wheelbase with a capacity of up to 10.16 tonnes (10 tons) including body a Rolatip exhibited by Ford is based on a six-wheeled DT2417 chassis, has a capacity of 20.32 tonnes (20 tons) and is equipped with special roller jacks at the rear which automatically fold up under the chassis when the vehicle starts to move.

Exemplifying the increasing use of drawbar demountables for some types of traffic, a trailer can be seen in the demonstration park fitted with a Freight BonaHack Loadspeeder straight-lift demount system, and A. C. Penman is demonstrating indoors a Bedford TM chassis and a York drawbar trailer in the park. Each of the vehicles is equipped with Glasonit containers which are interchangeable between the two vehicles by means of Penman Power Hydraulics demountable systems.

In a different type of demountable category, an Airportable container on the Marshall stand houses a mobile military workshop and the handling gear provides for easy inter-vehicle transfer and lowering to ground level. And a Massey insulated medical container, designed for service in the tropics, has jacking tubes at the four corners to accommodate detachable jacking legs.

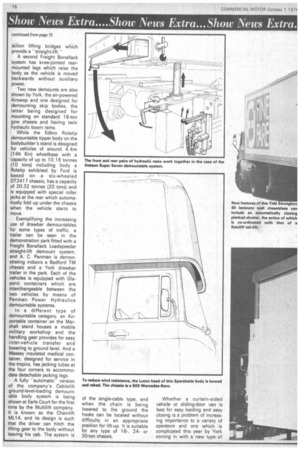

A fully "automatic" version of the company's Cablelift ground-level-loading demountable body system is being shown at Earls Court for the first time by the Multilift company. It is known as the Chainlift ML14, and its design is such that the driver can hitch the lifting gear to the body without leaving his cab. The system is of the single-cable type, and when the chain is being lowered to the ground the hooks can be located without difficulty in an appropriate position for lift-up. It is suitable for any type of 16-, 24or 30-ton chassis. Whether a curtain-sided vehicle or sliding-door van is best for easy loading and easy closing is a problem of increasing importance to a variety of operators and one which is complicated this year by York coming in with a new type of curtained vehicle in competition With the Boalloy award-winning Tautliner and by the display of a number of new sliding-door models by other companies.

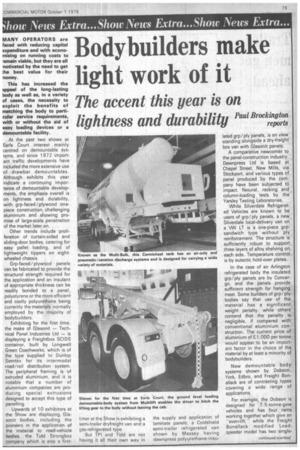

Known as the Sidewinder, the York curtain-sided semitrailer features wind-up curtains which give full-length, fullheight loading, the curtains being wound out of the way of a fork-lift truck being used for loading. Many improved features are to be found on the two Tautliners on view, including a low-friction pvc curtain track, a fold-away ratchet tensioner and a special thumb-released buckle; and Boalloy also offers two versions of the company's Linkliner sliding-side van, a Longhaul and an Urban model. Hinged doors at the rear of the Longhaul can be swung out to enable the flush-fitting sliding doors to be moved one way or the other to give access to any part of the floor to fork-lifted pallet loads.

WeIford Truck Bodies also shows both types of body, an all-aluminium curtain-sided canopy semi-trailer being on view together with a steelframed sliding-door van on a rigid chassis.

The three sliding doors on each side of a Cravens Hornelloy insulated dairy van fold flush with the floor when not in use, and the doors can be lifted clear of an obstruction caused by an out-of-place load: Tidd also offers a semi-trailer van with flush-fitting sliding doors which are claimed to give maximum interior width, the mechanism being known as Widerslider.

Curtain-sided or equipped with side roller shutters, the Glover-Hamble Ridge-back distribution vehicle of the type shown by Charrold has a side-loading height of only 280mm (11 in) the vehicle on show being a curtain-sided type.

It represents a combined design exercise by Daimler Benz and a German bodybuilder, Lampferhoff. The vehicle maker's chassis (in this case a Mercedes-Benz 1617) is cut off behind the cab and replaced by a robust central main beam from which the propeller shaft is underslung out of the way of four full-length loading bays, a fixed bay over the wheels having a higher floor.

If required, the body may be fitted with a raisable roof, as is the one exhibited, and it can be built with bays of a length to suit the customer.

Of the many bulk vehicles on view, the Carmichael Maxi-Bulk

multi-material non-tipping tanker is of special interest in that the material may be discharged by a -top-air-onlysystem or by an easy-clean aeration/pneumatic type, a removeable encapsulated seration unit being fitted to the base of each of the hoppers.

The tanker is mounted on a 32-ton gvw semi-trailer chassis and the discharge equipment may appropriately be compared with that of a Murfitt 611V series non-tipping pressure/vacuum tank which is mounted on a rigid chassis and is designed for the carriage of animal feedstuffs and grain.

This tank is divided into two separate sealed compartments, and the use of a Holmes 68 RBST blower provides for a change-over from pressure discharge to vacuum loading by operation of a single-control valve after attaching the hoses used for discharge to the vacuum inlet coupling at the rear.

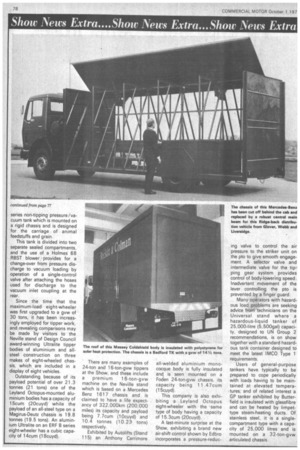

Since the time that the maximum-load eight-wheeler was first upgraded to a gvw of 30 tons, it has been increasingly employed for tipper work, and revealing comparisons may be made by visitors to the Neville stand of Design Council award-winning Ultralite tipper bodies of aluminium and allsteel construction on three makes of eight-wheeled chassis, which are included in a display of eight vehicles.

Outstanding because of its payload potential of over 21.3 tonnes (21 tons) one of the Leyland Octopus-mounted aluminium bodies has a capacity of 15cum (20cuyd) while the payload of an all-steel type on a Magirus-Deutz chassis is 19.8 tonnes (19.5 tons). An aluminium Ultralite on an ERF B series eight-wheeler has a cubic capacity of 14cum (18cuyd). There are many examples of 24-ton and 16-ton-gvw tippers at the Show, and these include a premium 16-ton-gvw machine on the Neville stand which is based on a Mercedes Benz 1617 chassis and is claimed to have a life expectancy of 322,000km (200,000 miles) its capacity and payload being 7.7cum (10cuyd) and 10.4 tonnes (10.23 tons) respectively.

Exhibited by Autolifts (Stand 115) an Anthony Carrimore all-welded aluminium monococque body is fully insulated and is seen mounted on a Foden 24-ton-gvw chassis, its capacity being 11.47cum (15cuyd)_

This company is also exhibiting a Leyland Octopus eight-wheeler with the ,same type of body having a capacity of 15.3cum (20cuyd).

A last-minute surprise at the Show, exhibiting a brand new air-shift control shown by Edbro incorporates a pressure-reduc ing valve to control the air pressure to the striker unit on the pto to give smooth engagement. A selector valve and intermediate valve for the tipping gear system provides control of body-lowering speed. Inadvertent movement of the lever controlling the pto is prevented by a finger guard.

Many operators with hazardous load problems are seeking advice from technicians on the Universal stand where a hazardous-liquid tanker of 25,000-litre (5,500gal) capacity, designed to UN Group 2 recommendations, is on show together with a standard hazardous tank container designed to meet the latest IMCO Type 1 requirements Users of general-purpose tankers have typically to be prepared to cope periodically with loads having to be maintained at elevated temperalures; and of related interest a GP tanker exhibited by Butterfield is insulated with glassfibre and can be heated by limpettype steam-heating ducts. Of stainless steel, it is a singlecompartment type with a capacity of 25,000 litres and is mounted on a 32-ton-gvw articulated chassis.