Pirelli's new Vizzola test track cuts out guesswork

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

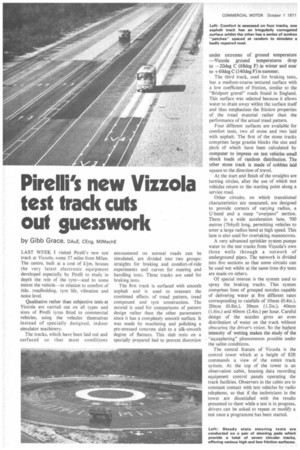

by Gibb Grace, DAuE, CEng, MIMechE LAST WEEK I visited Pirelli's new test track at Vizzola, some 37 miles from Milan. The centre, built at a cost of Vim, houses the very latest electronic equipment developed especially by Pirelli to study in depth the role of the tyre—and to some extent the vehicle—in relation to comfort or ride, roadholding, tyre life, vibration and noise level.

Qualitative rather than subjective tests at Vizzola are carried out on all types and sizes of Pirelli tyres fitted to commercial vehicles, using the vehicles themselves instead of specially designed, indoor simulator machinery.

The tracks, which have been laid out and surfaced so that most conditions encountered on normal roads can be simulated, are divided into two groups: straights for braking and comfort-of-ride experiments and curves for steering and handling tests. Three tracks are used for braking tests.

The first track is surfaced with smooth asphalt and is used to measure the combined effects of tread pattern, tread compound and tyre construction. The second is used for comparisons of pattern design rather than the other parameters since it has a completely smooth surface. It was made by machining and polishing a pre-stressed concrete slab to a silk-smooth degree of flatness. This slab rests on a specially prepared bed to prevent distortion

under extremes of ground temperature —Vizzola ground temperatures drop to — 20deg C (68deg F) in winter and soar to +60deg C (140deg F) in summer.

The third track, used for braking tests, has a medium-coarse textured surface with a low coefficient of friction, similar to the "Bridport gravel" roads found in England. This surface was selected because it allows water to drain away within the surface itself and thus emphasizes the friction properties of the tread material rather than the performance of the actual tread pattern.

Four different surfaces are available for comfort tests, two of stone and two laid with asphalt. The first of the stone tracks comprises large granite blocks the size and pitch of which have been calculated by computer to impress on test vehicles small shock loads of random distribution. The other stone track is made of cobbles laid square to the direction of travel.

At the start and finish of the straights are turning circles, after the use of which test vehicles return to the starting point along a service road.

Other circuits, on which transitional characteristics are measured, are designed to provide corners of varying radius, a

U-bend and a steep -overpass" section. There is a wide acceleration lane, 700

metres (766yd) long, permitting vehicles to enter a large radius bend at high speed. This lane is also used for overtaking manoeuvres. A very advanced sprinkler system pumps water to the test tracks from Vizzola's own three wells through a network of' underground pipes. The network is divided into five sections so that some circuits can be used wet whilst at the same time dry tests are made on others.

Of special interest is the system used to spray the braking tracks. This system comprises lines of grouped nozzles capable of delivering water at five different rates corresponding to rainfalls of lOmm (0.4in.), 20mm (0.8in.), 30mm (1.2in.), 40mm (1.6in.) and 60mm (2.4in.) per hour. Careful design of the nozzles gives an even

distribution of water on the track without obscuring the driver's vision. So the highest intensity of wetting makes the study of the "aquaplaning" phenomenon possible under the safest conditions.

The central feature of Vizzola is the control tower which at a height of 82ft

commands a view of the entire track system. At the top of the tower is an observation cabin, housing data recording equipment control panels operating the track facilities. Observers in the cabin are in

constant contact with test vehicles by radio telephone, so that if the technicians in the tower are dissatisfied with the results presented to them while a test is in progress, drivers can be asked to repeat or modify a test once a programme has been started.