What to Do in Emergencies.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

During the first periods of the war, we have substituted this new feature for our usual "Drivers' and Mechanics' Contributions"; these we shall, next week, re.&ume, now that more settled circumstances rule. We repeat our recent statement, that we are desirous of assisting the "new man at the wheel," of whom there are many at the present time for one reason or another. Our ususil "D. and .M. "pages have included many tips as to workshop procedure, etc. ; some of these we have temporarily dropped. We shall now revert id the same class of

contribution as hitherto. Our usual weekly 10s. prize for the best contribution will also be resumed.

Contributions from Drivers and Mechanics.

We again notify readers of our intention, next week, to resume the publication of our much-appreciated "P. and M." pages. All -communications utilized will be paid for at the same rates as hitherto.

For the benefit of new readers, we may mention that each week a prize of 10s. will be offered for the best contribution sent in by either a driver or mechanic. Any other letters published will be paid for at the rate of one penny a line of ten words. Communications must relate to some special incident or experience on the roadside, garage or workshop, and must be of general interest to men who are directly employed in connection with commercial vehicles. When required a rough sketch may accompany the letter ; this will be redrawn if necessary.

Cleaning a Foul Gauge-Glass.

Sometimes it happens on a steam wagon that the water level in the boiler cannot be ascertained owing to the gauge-glass being foul through congealed oil. An easy method of cleansing the tube is to hold a piece of steel, which has previously been made redhot, in front of the glass. The oil will then be melted and will leave the glass in quite a clean condition.

Repairing a Fractured Valve-Chest Cover.

The accompanying illustration shows how a very effective repair can be ,carried out to a fractured valve-chest cover. The repair is very ingenious, for the reason that, in effect, the crack is tightly compressed together during the process of the repair.

The procedure is as follows :—Two 4 in. tapping holes should be drilled in the cover, one each side the fracture and in reasonably close proximity thereto ; they are then tapped out 4 in. Whitworth. Two 4 in. studs should then be made which are provided with a small eccentric near each end, after the shape shown in the detail sketch. The height of the eccentric from the base of the stud is, of course, determined by the depth of tapping into the valve-box.

A piece of mild-steel plate # in. thick will serve the purpose of a cover ; into this are filed two slots, their distance apart being equal to the pitch of the two studs when the latter are in position. The outer face of each slot, it will be noticed, is circular in form, and the highest point of the arcs must be in contact with the studs when each eccentric is nearest the fracture. 'Before placing the cover in position, a solution of sal ammoniac may be applied to the crack. The studs should be threaded into the valve-chest, and the coverplate fixed in position. Each stud must then be turned to about 90 degrees, when the ectentrie or cam will commence to face up against the circular-shaped apertures in the plate. During the operation of screwing, a leverage is exerted which tends to close the fracture and so make a good steam-tight joint.

Joining a Chain.

When attention is necessary to a roller chain of large pitch, such as is used in the main transmission of steam wagons and petrol lorries, it is not always an easy matter, after the replacement of links or

renewal of link-pins has been made, readily to join up the chain again. The sketch herewith should help to show how the difficulty may be readily overcome.

The equipment comprises a piece of tough rope of a. diameter small enough to allow it to be threaded through the links of the chain. A small bolt should be tied to one end and the rope passed through a link nearest the joint. The rope should then be threaded after the manner shown in the sketch. Any top slackness, in the chain can be taken out by moving the machine along "in gear." The rope should then be tightened, and, by its acting as a kind of pulley block, the other end of the chain will be brought into such a position as to enable the binding link or half-link to be fixed in position.

Adjusting Wipe Contact-Breakers.

As a general rule, wipe contact-breakers are selfadjusting by means of the light coil-spring which is fitted. When any real-adjustment here is noticed, an easy method of rectifying it is to bend the blade in order to give it extra tension. The blade must not be excessively distorted, however, as a prolonged contact of the make-and-break cam wastes current.

The points in contact should be kept clean and slightly lubricated. The fibre and metallic surfaces must be kept even, as any inequalities will cause the wiper to jump, with the result that irregular firing is aggravated.

Repairing Worn Connecting-Rod Bushes.

in engines which have been running for some considerable time, it may be necessary to re-bush the small-ends of the connecting rods, as the excessive wear will set up too much play at that point. Instead, however, of resorting at once to a renewal of the bushes, a very satisfactory repair can sometimes be effected by the following method. The faulty bush should be detached from the connecting rod, and this can be accomplished by pressing it out of position in a vice. After thoroughly cleaning the bush, a layer of solder should be sweated inside the bore. This coating, if carefully applied, will reduce the diameter a few thousandths of an inch and will so make up for the worn metal. This speedy remedy can be resorted to in the case of other small bushes throughout the chassis.

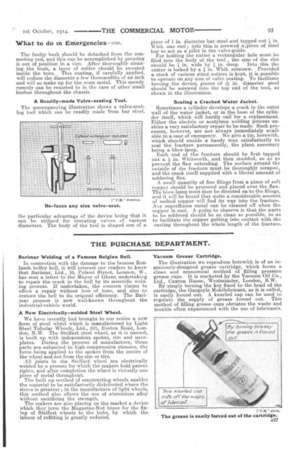

A Readily-made Valve-seating Tool.

The accompanying illustration shows a vaIve-seating tool which can be readily made from bar steel, the particular advantage of the device being that it can be utilized for reseating valves of various diameters. The body of the tool is shaped out of a

piece of 1 in. diameter bar steel and tapped out Whit. one end ; into this. is screwed atpiece of steel bar to act as a pilot in the valve-guide. For holding the cutter a rectangular hole must be filed into the body of the tool the size of the slot should he 1 in. wide by in. deep. Into this the cutter is locked by a t, in. Whit. setscrew. Provided a stock of various sized cotters is kept, it is possible to operate on any size of valve seating. To facilitate turning the device, pieces of As in. diameter steel should be screwed into the top end of the tool, as shown in the illustration.

Sealing a Cracked Water Jacket.

Sometimes a cylinder develops a crack in the outer wall of the water jacket, or in the base of the cylinder itself, which will hardly call for a, replacement. Either the electric or acetylene welding process enables a very satisfactory,repair to be made. Such processes, however, are not always immediately available in a case Of emergency. We give a tip, herewith, which should enable a handy than satisfactorily to seal the fracture permanently, the Plant necessary being a blow-lamp.

Each end of the fracture should be first tapped out a 1 in. Whitworth, and then studded, so as to prevent the flaw extending. The surface around the outside of the fracture must be thoroughly scraped, and the crack. itself supplied With a liberal amount of soldering flux. A small quantity of fine filings from a piece of soft copper should be procured and placed over the flaw. The blow-lamp must then be directed on-to the filings, and it will be found that quite a considerable amount of melted copper will find its way into the fracture. Aey superfluous metal can be cleaned off when the copper is cool. A -point to observe is that the parts to be soldered should be as clean as possible, so as to facilitate the copper getting into contact with, the casting throughout the whole length of the fracture.