Weight-saving Scheme for Double-deckers

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

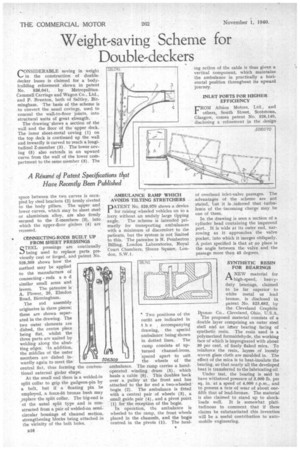

CONSMERABLE saving in weight in the construction of doubledecker buses is claimed for a bodyb-ailding refinement shown in patent No. 526,041, by MetropolitanCammell Carriage and Wagon Co., Ltd., and P, Brunton, both of Saltley, Birmingham. The basis of the scheme is to convert the usual covings, used to conceal the wall-to-floor joints, into structural units of great strength.

The drawing-shows a section of the wall and the floor of the upper deck. The inner sheet-metal coving (1) on the top deck is continued up the wall and inwardly is curved to reach a longitudinal Z-inernber (3). The lower coving (5) also extends in an upward curve from the wall of the lower compartment to the same member (3). The space between the two curves is occu• pied by steel brackets (2) firmly riveted to the body pillars. The upper and lower curves, which may be sheet steelor aluminium alloy, are also firmly secured to the Z-members(3), into which the upper-floor girders (4) are recessed.

• CetNNECTING-RODS BUILT UP FROM SHEET PRESSINGS Q TEEL pressings are continually being used to replace parts pre viously cast or forged, and patent No. 526,309 shows how the method may be applied to the manufacture of connecting rods a n d similar small arms and levers. The patentee is A. Flower, 20, Elrndon Road, Birmingham.

The rod assembly originates in three pieces; these are shown separated in the drawing. The two outer elements are dished, the centre piece being flat, whilst the three parts are united by welding along the abutting edges. -In addition, the middles of the outer members are dished inwardly again to meet the central fiat, thus forming tional external girder shape.

At the small end there is a welded-in

split collar to grip the gudgeon-pin by a bolt, but if a floating pin be employed, a force-fit bronze bush may ,replace the split collar. The big-end is

of the ustial split type and is constructed from a pair of welded-on semicircular housings of channel section, strengthening blocks being attached in the vicinity of the bolt holes. the coniren

PATENT No. 526,070 shows a device for raising wheeled vehicles on to a lorry, without an unduly large tipping angle. The scheme is intended primarily for transporting ambulances with a minimum of discomfort to the patients, but the system is not limited to this. The patentee is N. Pemberton Billing, London Laboratories, Royal Court Chambers, Sloane Square, London, S.W.].

in dotted lines. The ramp consists of upturned channel-irons, spaced apart to suit the wheels of the ambulance. The ramp carries a handoperated winding drum (5), which hauls a cable (6). This doubles back over a pulley at the front and has attached to the far end a two-wheeled bogie (2) The ambulance is fitted with a central pair of wheels (3), a small guide pair (4), and a pivot point (1) for the reception of the bogie.

In operation, the ambulance is wheeled to the ramp, the front wheels placed in the channels, and the bogie centred in the pivots (1). The haul ing action of the cable is thus given a vertical component, which maintains the ambulance in practically a horizontal position throughout its upward journey.

INLET PORTS FOR HIGHER EFFICIENCY

FROM Albion Motors, Ltd., and others, Smith Street, Scotstoun, Glasgow, comes patent No. 526,140, disclosing a refinement in the design

of overhead inlet-valve passages.. The -advantages of the scheme are not stated, but it is inferred that turbu: lence of the 'incoming charge may be one of them.

In the drawing is seen a section of a cylinder head containing the improved port. It is wide at its outer end, narrowing as it approaches the valve pocket, into which it merges obliquely. A,point specified is that at no place is the angle between the valve and the passage more than 45 degrees. • SYNTHETIC RESIN . FOR BEARINGS

ANEW material for high-speed, heavyduty bearings, claimed to be far superior to white metal or lead bronze, is disclosed in patent No. 525,682, by the Cleveland Graphite Bronze Co.. Cleveland, Ohio, U.S.A. The proposed material consists of a double layer comprising an outer steel shell and an bitter bearing facing of synthetic resin. -The resin used is a polymerized formaldehyde, the working face of which is impregnated with about 30 per cent, of finely flaked mica. To reinforce the resin, layers of loosely woven glass cloth are moulded in. The effect of the mica is to heat-insulate the bearing, so that nearly all the developed heat is transferred to the lubricating oil Under test, the bearing is said to have withstood pressure of 3,00'0 lb. per sq. in. at a speed of 4,000 r.p.m., and to possess a rate of wear of about onefifth that of lead-bronze. The material is also claimed to stand up to shock. loads well. It is somewhat plati. tudinous to comment that if these claims be substantiated this invention will be a useful contribution to automobile engineering.