THE INFLUENCE of the

Page 90

Page 91

Page 92

Page 93

If you've noticed an error in this article please click here to report it so we can fix it.

[ORIZONTAL ENGINE ON FUTURE \/ ICLE DESIGN

An Engineer-designer of Exceptional Experience and Ability Gives His Unconventional Views on the Layout of Commercial Vehicles for the Transport of Goods and Passengers

By L. A. POOLE, M.I.A.E.

WHILE reviewing the developments in the design of passenger and goods vehicles that have recently taken _ place in this country, it is quite obvious that commendable endeavours have been made to meet the required conditions relating to increased seating capacity, enlarged goods-carrying space and the reduction of chassis weight. It must be admitted that a considerable degree of success in these directions has already been achieved. It is, however, obvious that designers have had their ingenuity taxed to the utmost in striving to obtain these advantages on chassis layouts incorporating present-day accepted practice in engine design.

The problem still before designers is how to utilize the whole of the body space to give the maximum accommo

dation for goods or passengers. It therefore occurs to the writer that, so long as the orthodox vertical type of engine is retained, with its inherent disadvantage of requiring undue head room when installed in any position in the chassis, design will be controlled mainly by this factor. There is, therefore, little prospect of arriving at a state where interference from this cause can be ignored.

D32 Much interest has been aroused by the efforts of designers, both in this country and America. to overcome this 'head-room" obstacle, and radical changes have been made in the positioning of the engine in its chassis. In various models the power unit has been placed sideways or transversely, as well as in other positions permitted by the orthodox engine, without,' however, in the writer's opinion, finding a definite solution of the problem.

If we are to obtain this ideal layout, utilizing the body space to absolutely the utmost advantage, it is imperative that the floor space be devoid of any projection from the underside or elsewhere, due, to engin,: encroachment.

To accomplish this, development must be made on the lines of using a much more compact power unit, occupying little head roomand yet possessing all the characteristics of present-day high-efficiency engines, coupled with that very important factor, accessibility. It would seem that all these conditions are completely met in the horizontally opposed, or "fiat " engine and, in the writer's opinion, the adoption of this type of engine for practically all types of chassis would undoubtedly solve many knotty problems'of layout.

This design of engine satisfies the need for minimum head room and occupies practically half the length of the orthodox " in-line engine with the same number of 'cylinders; it is lighter and should cost less to produce, at the same time it can be arranged in the chassis so as to be very accessible ford maintenance and repairs.

The disposition of such an engine gives an accepted normal driving layout and low centre of gravity; in fact. it may be said that a horizontal engine, provided that it be placed in the cornet position for each type of chassis.

seems to be peculiarly adaptable.

The use of the fiat engine for the purpose indicated is, of course, not new, and in the early days of the industry great controversy raged between the various makers as to whether this or the vertical type possessed the greater advantages—the latter, however, came into vogue, mainly because it could be plated under a bonnet at the front, thereby eliminating the " horseless " appearance of the vehicle, and following the trend established by Levassor's design.

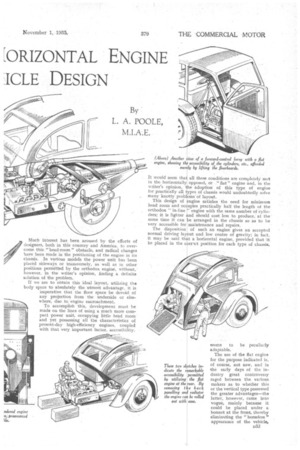

It will perhaps be of interest to note the efforts that have recently been made in other countries and more particularly in Germany. In this connection the Hanomag Co. some time ago introduced an interesting lorry having a four-cylindered oil engine of 105 ram. bore and 150 mm. stroke, developing 60 b.h.p., slung horizontally under the frame, behind the front axle.

This 4--ton lorry has since become extremely popular in Germany, and the same company has now developed a four-wheel-driving and steering vehicle, with the engine amidships, which is ideally situated for this purpose. Again, in America, the White Co. of Cleveland has for some time been manufacturing lorries of large capacity, equipped with a 12-cylindered "pancake "-type engine of 93 mm. bore and 95 mm. stroke, developing 131 b.h.p. In this case the engine is mounted under the driver's footboards—immediately over the front axle; such a disposition gives adequate room for three persons to sit abreast in the cab.

Further, the Hall Scott engine of 5-in, bore and 6-in. stroke, giving 180 b.h.p., has been developed for mounting beneath 40-seater coaches, enabling all the floor space

above to be utilized solely for passenger accommodation. It is understood that this form of layout is gaining favour in the United States.

In advocating the horizontal engine, the writer feels some hesitancy, mainly on account of the expense involved, in suggesting that manufacturers should break away from conventional design and produce engines on the revised lines. It is apparent, however, that, in these highly competitive times, those who are prepared to develop design with the object of obtaining the utmost passenger or goodscarrying space, are bound to reap the benefit in the long run.

Using a Normal Engine at the Rear.

After analysing the matter the writer suggests that it would be quite feasible to utilize the present vertical-type engine, by laying it horizontally in the chassis for general goods-carrying vehicles, and that it would be necessary only in the case of specialized vehicles, such as large coaches and buses, to incorporate the opposed type of engine.

If the former procedure were to be adopted—on the lines already mentioned in the case of the Hanomag—it would entail only minor alterations, These would include the lubrication system, placing the oil pump vertically, revision of the water-cooling return pipes, and probably methods of engine suspension, but in the main the bulk of parts and the general layout could be retained. '

It is agreed that a horizontal engine of this type may appear unsymmetrical, but the advantages accruing from the new position would much outweigh this point. As will be seen from the illustrations, by removing the basechamber plate; immediate access is given to the big-ends and main bearings; also, on the other' side of the chassis, by removing the cover plate inthe case of an overheadvalve engine, the sparking plugs, or injectors, as the case may be, can easily be removed, the valve and tappet clearances adjusted or the combustion head 'detached—ail rapidly and in comfort. , .D34 It will therefore be seen the engine in this position would appear to be more " get-at-able " than usual, whilst giving the largest available load area, for a given overall length of vehicle. The Hanomag chassis has an overall length of 19 ft. on a wheelbase of only 11 ft. 7 ins. ; front track, 5 ft. 4i ins. ; rear track, 5 ft. 2i ins., but despite these small dimensions the available loading space is 13 ft. by 1i in. by 6 ft. 7 ins., and the driver's cab over the front axle is so spacious that it can accommodate four adults. Incidentally, this lorry can be turned in a road 26 ft. wide.

Most Suitable Engine Layouts.

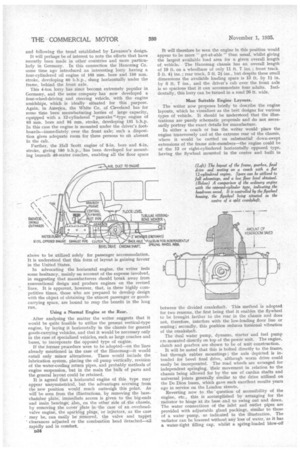

The writer now proposes briefly to describe the engine layouts, which he visualizes as the brit designs for various types of vehicle. It should be understood that the illustrations are purely schematic proposals and do not necessarily portray the exact details for manufacture.

In either a coach or bus the writer would place the engine transversely and at the extreme rear of the chassis, where it would be carried on substantial down-swept extensions of the frame side-members—the engine could be of the 12 or eight-cylindered horizontally opposed type, having the flywheel mounted in the centre and built hi between the divided crankshaft. This method is adopted for two reasons, the first being that it enables the flywheel to be brought farther to the rear in the chassis and does not, therefore, interfere with the low-loading floor line or seating ; secondly, this position reduces torsional vibration of the crankshaft.

The dual water pump, dynamo, starter and fuel pump are mounted directly on top of the power unit. The engine, clutch and gearbox are shown to be of unit construction.

It will be noted that this is bolted directly to the frame, but through rubber mountings ; the axle depicted is intended for bevel final drive, although worm drive could easily be incorporated. The road wheels are arranged for independent springing, their movement in relation to the chassis being allowed for by the use of cardan shafts and universal joints generally similar to the drive utilized on the De Dion buses, which gave such excellent results years ago in service on the London streets.

Reverting now to the question of accessibility of the engine, etc., this is accomplished by arranging for the radiator to hinge at its base and to swing out and down. The water connections of the inlet and outlet pipes are provided with adjustable gland packings, similar to those of a water • pump, as indicated in the illustration. The radiator can be lowered Without any loss of water, as it has a water-tight filling cap, whilst a spring-loaded blow-off valve is fitted in case of extreme teinperature arising from any cause. It will be seen, therefore, that easy access is afforded to the electrical units, pumps, or fan.

In the event of it being necessary to adjust the valve tappets, injectors, etc., these may readily be dealt with by reason of the side doors, which are hinged and louvred. The air passed through the radiator is drawn down two ducts from the

roof, and after passing over the engine compartment is expelled outwards through the radiator core In view of this air flow the possibility of " gassing " inside the body-7-so prevalent in the usual type of vehicle—is obviated.

Should it at any time be necessary to remove the engine from the chassis, the radiator, rear and side panels can be detached, the engine and rear axle retaining bolts removed and the entire unit wheeled outwards on its rollers. It will be seen that this layout gives the utmost accessibility and yet meets all the required conditions.

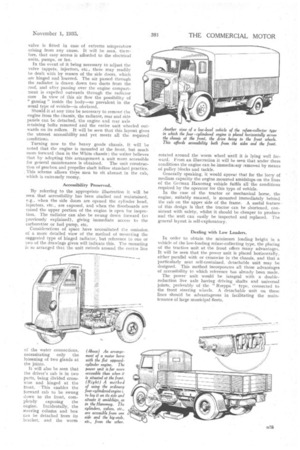

Turning now to the heavy goods chassis, it will be noted that the engine is mounted at the front, but much more forward than in the White chassis; the writer believes that by adopting this arrangement a unit more accessible for general maintenance is obtained. The unit construction of gearbox and propeller shaft follow standard practice. , This scheme allows three men to sit abreast in the cab, which is extremely roomy.

Accessibility Preserved..

By referring to the appropriate illustration it will be seen that accessibility has been studied and maintained, e.g., when the side doors are opened the cylinder head, injectors. etc., are exposed, and when the floorboards are . raised the upper portion of the engine is open for inspection. The radiator can also be swung down forward (as Previously explained), giving immediate access to the

carburetter. or fuel pimp, etc.. . .

Considerations of space have necessitated the omission. of a more detailed view of the method of mounting the suggested type of hinged radiator, but reference to one or two of the drawings given will indicate this. The mounting is so arranged that the unit swivels around the centre line of the water connections, necessitating only the loosening of two glands at the joints.

It will also be seen that the driver's cab is in two parts, being divided crosswise and hinged at the front. This enables the forward cab to be swung down to the front, completely exposing the engine. Incidentally, the steering column and box can be detached from its bracket, and the worm rotated around the worm wheel until it is lying well forward. From an illustration it will be seen that under these conditions the engine can be immediately removed by means of pulley blocks and tackle.

Generally speaking. it would appear that for the lorry of medium capacity the engine mounted amidships on the lines of the German Hanornag vehicle fulfils all the conditions required by the operator for this type of vehicle.

In the case of the tractor or mechanical horse, the engine, suitably encased, is mounted immediately behind the cab or. the upper side of the frame. A useful featureof this design is that the tractor can be shortened, consistent with safety, whilst it should be cheaper to produce and the unit can easily be inspected and replaced. The general layout is self-explanatory.

Dealing with Low Loaders.

In order to obtain the minimum loading height in a vehicle of the low-loading refuse-collecting type, the placing of the tractive unit at the front offers many advantages. It will be seen that the power unit is placed horizontally, either parallel with or crosswise in the chassis, and that a particularly neat self-contained, detachable unit may be designed. This method incorporates all those advantages of accessibility to which reference has already been made. The power unit would be integral with a doublereduction live axle having driving shafts and universal joints, preferably of the " Rzeppa " type, connected to the front steering wheels. A detachable unit on these lines should be advantageous in facilitating the maintenance of large municipal fleets,