Spirited Performanc( with Economy

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

AMAXIMUM speed of more than 70 m.p.h., acceleration on

• a par with that of current 5-cwt. and I0-cwt. vans, and a fuel consumption rate of 21.7 m.p.g. nonstop fully laden were among the out standing. results obtained with a Bedford 35-cwt. van which I recently road tested.

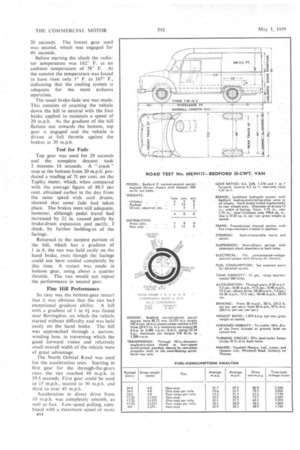

With. bodywork by Hawson, Ltd., the van is based on the Bedford J1 119 in. Wheelbase normal control chassis. This is the smallest model in the normal-control range introduced last year and is the third of the new models to b'e tested by The COIMITETch.,' Motor.

The basic Ji chassis is used for both 25-cwt. and 35-cwt. models. For the lighter application 7.50-16-in. tyres are used, which are normally replaced on the rear wheels, in conjunction with heavier springs, by 8.25-16-in. 12-ply tyres when the vehicle is rated for a 35-cwt. payload.

The use of larger tyres on the rear wheels of the 35-cwt. raises a number of problems. It increases loading height and gives the vehicle a tail high appearance. Moreover, operators, particularly in this country, do not like to have different tyre sizes on one vehicle.

These problems were overcome on the van which I tested by using Michelin X 7.50-16-in. tyres all round. These have the same load rating as conventional 8.25-16-in. covers. The centre of gravity of the vehicle remains low, whilst a useful reduction in unladen weight is achieved. B12 The J1 may be powered either by the 241-cu.-in. six-cylindered petrol engine or the 200-cu.-in, oil engine. The test vehicle had the petrol engine, Which has a net output of 86 b.h.p.

A close-ratio synchromesh gearbox' is used with both engines, the drive being taken through a two-piece propeller shaft to the spiral-bevel rear' axle. Two axle ratios are available, the test vehicle hailing the higher ratio of 4.37 to 1, which is used normally with the petrol engine.

The Hawson body incorporates the Bedford front end, with its deeply sloping bonnet which permits forwardControl-like visibility.. Use of the standard Bedford one-piece curved windscreen ensures easy and cheap replacement of this component when necessary. The cab is taken out to the full width of the integral body, and curved front quarter-lights are fitted to enhance forward vision..

The body is all steel, with either a wooden or a steel floor, and employs part-welded and part-riveted construction. It provides 300 cu. ft. of space behind the seats, with at least a further 40 Cu. ft. beside the driver, if no passenger seat is fitted.

Sliding doors which provide wide apertures simplify access to the, interior of the body or to the driving seat, whilst, because of the normalcontrol layout, the driver can reach his seat with ease from the near side. The doors are fitted externally and do not occupy body space. A protective second skin is fitted inside the body up to 2 ft. 6 in. from the floor and the wheel-boxes are flat-topped.

The hinged rear doors on the test vehicle—roller shutters and combina Lions of roller shutters and tailboards are also available—incorporate two large windows. Their hinges allow, them to be swung back against the body sides, where they are automatically secured by spring-loaded keepers.

A number of extras is available with this body, including a translucent plastics roof panel (which is probably unnecessary unless a full-height bulkhead is fitted behind -the seats), a double or single passenger seat, and interior lashing rails. The standard roof line may also be raised to give extra internal capacity.

The van benefits greatly from the use of 16-in.-diameter wheels. They permit a loading height of only 2 ft. 7 in. when 7.50-16-in. tyres are fitted and contribute to the excellent turning circle of the vehicle (39 ft.), which compares most favourably with that of some forward-control designs of the same or smaller capacity.

Unladen, the test van weighed 2 tons 2 cwt. Sandbags totalling 1 ton 141 cwt, were added to bring the weight of the vehicle, complete With myself and Colin Prebble, of Vauxhall Motors, Ltd., to the recommended maximum gross weight of 4 tons.

Of this amount, 1 ton 8 cwt. was carried by the front axle, with 2 tons 12 cwt. on the rear, wheels—the sort of weight distribution that one expects with a normal-control design. Less weight on the front axle does ensure light steering and this, in conjunction with the good lock provided, makes the Bedford an easy vehicle to get into and out of tight corners.

For the fuel-consumption runs I took the van to our usual test circuit on the A6 road between Barton and Clophill. Made-up of out-and-return legs over an undulating course, each test run totalled six miles.

• During the non-stop runs the speedometer was kept at just over 30 m.p.h. when possible, whilst on the • stopping runs the vehicle was halted for 15 seconds with the engine idling during each stop. So lively was the performance that it was difficult to keep the speed down to the required figure.

The results showed again that to use a larger engine than is normal does not inevitably create extravagance in fuel consumption, provided that the overall gear ratios are correctly chosen. Moreover, as later tests demonstrated conclusively, it is obviously not a question of using hign ratios to improve economy at the expense of performance. The figure obtained non-stop at full load is exceptional, whilst the four-stops-per-mile figure of 13.3 m.p.g. is nothing to be ashamed of with a petrol-engined vehicle running at a gross weight of 4 tons.

These results can be compared with those obtained by Vauxhall Motors with a similar vehicle running at the same weight, but fitted with their fourcylindered 200-cu.-in. oil engine. Over a 95-mile course the van gave a fuel return of more than 29 m.p.g. at an average speed of about 30 m.p.h. Even with an exceptional performance from the petrol engine, the oiler still has a clear advantage over it, once the initial cost has been discounted.

Braking trials were conducted on a quiet, dry by-road. It had been noted that the brake-pedal action on the test vehicle was very hard at the beginning of the test. Although the vehicle had completed 3,000 miles it had done little, if any, laden mileage.

Thus, the brakes had, in the main, been lightly applied, causing the moulded facings to glaze without properly bedding-in. The braking distances obtained were satisfactory, although a higher pedal pressure than is desirable was required to achieve maximum retardation.

Towards the end of the complete test the pedal action was becoming lighter and I think that had the brakes\

been tested again at this point, the distances would have been reduced. The brakes certainly did bed-in during the test, as I found when I adjusted • them during the maintenance checks.

From 20 m.p.h. the rear wheels locked immediately the pedal was depressed, but the less heavily loaded front wheels did not skid. All four wheels locked when braking from 30 m.p.h. In both cases braking was equal on each side of the vehicle and no marked loss of directional stability occurred.

The pull-up hand brake was extremely effective, locking the rear wheels immediately it was applied and giving a reading on the Tapley meter of 40 per cent.

Bison Hill, near Whipsnade, was chosen for the hill test. The 4-mile climb, which has an average gradient of 1 in 101, was made in 2 minutes 20 seconds. The lowest gear used was second, which was engaged for 40 seconds.

Before starting the climb the radiator temperature was 162° F. at an ambient temperature of 58° F. At the summit the temperature was found to have risen only 5° F. to 167° F., indicating that the cooling system is adequate for the most arduous operation.

The usual brake-fade test was made. This consists of coasting the vehicle down the hill in neutral with the foot brake applied to maintain a speed of 20m.p.h. As the gradient of the hill flattens out towards the bottom, top gear is engaged and the vehicle is driven at full throttle against the brakes at 20 m.p.h.

Test for Fade Top gear was used for 29 seconds and the complete descent took 2 minutes 16 seconds. A "crash" stop at the bottom from 20 m.p.h. produced a reading of 71 per cent. on the Tapley meter, which, when compared with the average figure of 88.5 per cent. obtained earlier in the day front the same speed with cool drums, showed that some fade had taken place. The brakes were still adequate, however, although pedal travel had increased by 21 in. caused partly by brake-drum expansion and partly, I think, by further bedding-in of the facings.

Returned to the steepest portion of the hill, which has a gradient of 1 in 6, the van was held easily on the hand brake, even though the facings could not have cooled completely by this time. A restart was made in bottom gear, using about a quarter throttle. The van would not repeat the performance in second gear.

Fine Hill Performance So easy was the bottom-gear restart that it was obvious that the van had exceptional gradient ability. A hill with a gradient of 1 in 41 was found near Bovingdon, on which the vehicle started without difficulty and was held easily on the hand brake. The hill was approached through a narrow, winding lane, in traversing which the good forward vision and relatively small overall width of the vehicle were of great advantage.

The North Orbital Road was used for the acceleration tests. Starting in first gear for the through-the-gears runs, the van reached 40 m.p.h. in 19.5 seconds. First gear could be used to 15 m.p.h., second to 30 mph. and third to over 45 m.p.h.

Acceleration in direct drive from 10 m.p.h. was completely smooth, as well as fast. Low-speed pulling, combined with a maximum speed of more

T314 than 70 m.p.h. (75 m.p.h. was recorded on a slight downward gradient), is a particularly pleasant feature of the van.

Suspension was noted to be good throughout the test and even when unladen there was little bouncing, To ascertain how the vehicle would perform on the type of rough surface which it might encounter on rural delivery work. I drove it along about a mile of pot-holed farm track.

The suspension, which incorporates shock absorbers on both axles, absorbed all but the most severe shocks. Even sitting on one of the rear wheel-arches while Colin Prebble drove at about 25 m.p.h. was not too Uncomfortable an experience.

Little Body Drumming

The body was quiet on the road, with—considering its all-steel con struction—little drumming. This is probably the result of comprehensive riveting of the main panels to the body framing. Although some chassis distortion must have been taking place at times on the rough track, the body did not complain audibly, an indication of the effectiveness of its mountings and the rigidity of the structure.

Good suspension was accompanied by cornering ability quite in keeping with the speed of the vehicle. When loaded it was difficult to induce roll, whilst when unladen, although understandably not quite so steady on corners at speed, the van still inspired confidence. Easy engine maintenance is usually one of the joys 'of normal-control vehicles and the Bedford is no exception, The 16-in, wheels enable a 6-ft. man to reach over the wings to most parts of the engine without the need for a step.

Although The Commercial Motor maintenance tests on petrol engines usually include the removal of a sparking plug, there seemed little point

• in carrying out this operation, as the plugs are not shrouded and present no difficulty. The bonnet lid is counterbalanced by springs and held down by a catch behind the radiator grille. The radiator water level is easy to check, whilst the dipstick is fully exposed and accessible.

The AC-Deko contact-breaker is' mounted low down at the centre point of the engine • on the off side. I was able to check the points in 1 minute 45 seconds, which included inserting the , starting handle and turning the engine over to the correct position. It was possible to turn the starting handle and watch the points at the same time.

Also easy to reach, although mounted low down in the engine compartment, the transparent plastics bowl of the fuel pre-filter was removed, emptied, cleaned and replaced in 1 minute 2 seconds. Mounted directly on the carburetter intake, the A.C. oil-bath air filter is secured by a contracting clip and a stay to stop vibration. One minute 55 seconds sufficed to detach it, remove and inspect the element, reassemble, and re-fit it.

Turning to the chassis, I checked the gearbox oil level in 35 seconds and the rear-axle oil level in 32 seconds. As the square-headed filler plugs are of different sizes, the same spanner could not be used for both Operations.

Normally in brake adjustment, the standard jack supplied with the vehicle is used by The Commercial Motor. However, having left the vehicle for a moment, I found that the Vauxhall service department had kindly put it up on a hoist. It seemed churlish to insist that it was brought down to ground level, so I adjusted the brakes with the vehicle in this position. The four nuts on the front backplates took 1 minute 15 seconds to take up, whilst the rather sharpedged, knurled adjusters for the rear brakes required 1 minute 7 seconds to re-set.

Jack Easy to Use

Although these times would have been increased by using a normal jack at ground level, there would have been no difficulty in using it. Clearance under the vehicle with 16-in. wheels still allows work to be carried out underneath it without jacking.

The normal Bedford-Hawson 35cwt, van with 8.25-16 in.-tyres on the rear wheels and the petrol engine costs £864. The test vehicle, however, with Michelin X tyres costs £851 15s. The oil-engined version is £105 more.