ROTRAN IN SOUTH AFRICA

Page 39

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

Coping with challenging conditions

Everyday is a winding road

Think you’ve got a tough job? Then find out what a heavy haulage operator in South Africa has to deal with

Words / images: Dennis Child

In terms of abnormal load conveyance in South Africa, the past 40 years have been challenging. The geographical conditions of the area have really tested man and machine in moving large, oversized cargo from ports inland to main infrastructure projects commissioned from the early 1970s onwards.

The country’s strict heavy haulage policy guidelines have resulted in a unique breed of equipment to comply with the regulations. These are similar to those adopted in California and Australia, and are designed to protect the civil structures/roads on the routes.

South Africa is not like Europe, where waterways and railways can be used to move such cargo. Huge road distances are common, and the longest route where loads are moved is more than 2,000km in one direction. All travelling is confned to daylight hours between Monday and Friday.

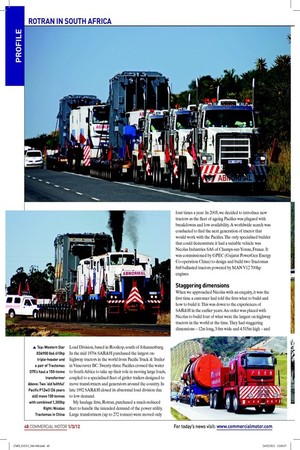

One of the most notable transporters was South African Railways and Harbour (SAR&H) Abnormal Load Division, based in Rooikop, south of Johannesburg. In the mid 1970s SAR&H purchased the largest onhighway tractors in the world from Paciic Truck & Trailer in Vancouver BC. Twenty-three Paciics crossed the water to South Africa to take up their role in moving large loads, coupled to a specialised leet of girder trailers designed to move transformers and generators around the country. In late 1992 SAR&H closed its abnormal load division due to low demand.

My haulage irm, Rotran, purchased a much-reduced leet to handle the intended demand of the power utility. Large transformers (up to 272 tonnes) were moved only four times a year. In 2005, we decided to introduce new tractors as the leet of ageing Paciics was plagued with breakdowns and low availability. A worldwide search was conducted to ind the next generation of tractor that would work with the Paciics. The only specialised builder that could demonstrate it had a suitable vehicle was Nicolas Industries SAS of Champs-sur-Yonne, France. It was commissioned by GPEC (Gujarat PowerGen Energy Co-operation China) to design and build two Tractomas 8x8 ballasted tractors powered by MAN V12 700hp engines.

Staggering dimensions

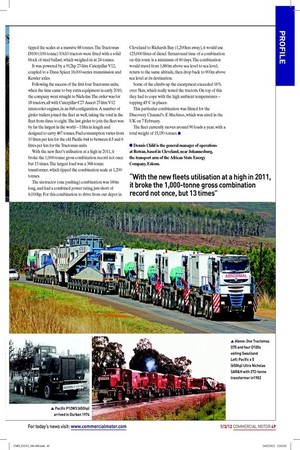

When we approached Nicolas with an enquiry, it was the irst time a customer had told the irm what to build and how to build it. This was down to the experiences of SAR&H in the earlier years. An order was placed with Nicolas to build four of what were the largest on-highway tractors in the world at the time. They had staggering dimensions – 12m long, 3.6m wide and 4.515m high – and tipped the scales at a massive 68 tonnes. The Tractomas D100 (100-tonne) 10x10 tractors were itted with a solid block of steel ballast, which weighed-in at 24 tonnes.

It was powered by a 912hp 27-litre Caterpillar V12, coupled to a Dana Spicer 16,000-series transmission and Kessler axles.