A PRIZE OP TEN SHILLINGS is awarded each week to

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

the sender of the best letter which we publish on this page: all others paid for at the rate of a penny a line, with an allowance for photographs, AU notes are edited before being

publiated. Mention vour employer's name, in confidence:. as evidence of good faith. Address D., M, and " The Commercial Motor," 7-la, Roseberu Avenue, London, E C.

Lamps Alight :—Saturday, 3rd March.

Light your lamps at 6.15 in London, 6.52 in Edinburgh, 6.17 in Newcastle, 6.24 in Liverpool, 6.21 in Birmingham, 6.25 in Bristol, and 7.7 in Dublin.

Cutting Paper Joints.

The sender of the following communication has been awarded the 10s, prize this week.

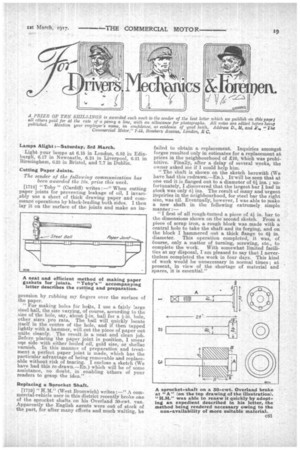

[17181 "Toby " (Cardiff) writes :—" When cutting paper joints for preventing leakage of oil, I invari,ably use a sheet of thick drawing paper and commence operations by black-leading both sides. I then lay it on the surface of the joints and make an ina

pression by rubbing my fingers over the surface of the paper.

" For making holes for boits, I use a fairly large steel ball, the size varying, of course, according to the

size of the hole, say, about i-in. ball for a hole, other sizes pro rata. The ball will quickly locate itself in the centre of the hole, and if then tapped lightly with a hammer, will cut the piece of paper out quite cleanly. The result is a neat and clean job. Before placing the paper joint in position, I smear oqe side with either boiled oil, gold size, or shellac varnish. In this manner of preparation and treatment a perfect paper joint is made, which has the particular advantage of being removable and replaceable without risk of tearing. I enclose a sketch (We have had this re-drawn.—ED.) which will be of some assistance, no doubt, in enabling 'others of your readers to grasp the idea."

Replacing a Sprocket Shaft.

[1719] " H.M." (West Bromwich) writes •—" A commercial-vehicle user in this district recently broke one of the sprocket shafts on his Overland 30-cwt. van. Apparently the English agents were out of stock of the part, for after many efforts and much waiting, he failed to obtain a replacement. Inquiries amongst forges resulted only in estimates for a replacement at prices in the neighbourhood of £10, tlich was prohibitive. Finally, after a delay of several weeks, the owner asked me if I could help him.

"The shaft is shown on the sketch herewith (We have had this redrawn.—En.). It-will be seen that at one end it is flanged out to a diameter of 61 ins. • unfortunately, I discovered that the largest box I 11;4 in stock was only 4 ins. The result of many and urgent inquiries in the neighbourhood, for steel bar the right size, was nil. Eventually, however, I was able to make a new shaft in the following extremely simple manner :— "I first of all rough-turned a piece of 4,1 in. bar to the dimensions shown on the second sketch. From a piece of scrap iron, a rough block was made with a central hole to take the shaft and its forging, and on the block I hammered out a thick flange to 6i in. diameter. This operation completed, it was, of 6ourse, only a matter of turning, screwing, etc., to complete the work. With somewhat limited facilities at ray disposal, I am pleased to say that I nevertheless completed the work in four days. This kind of work would be unnecessary in normal times ; at present, in view of the shortage of material and spares, it is essential."