up. Drivers &Mechanics

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best corn. munication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light Up Your Lamps At

4.58 on Thursday ; 5.0 on Friday ; 5.1 on Saturday; 5.3 on Monday ; 5.5 on Tuesday ; 5.6 on Wednesday.

Two Useful Tools.

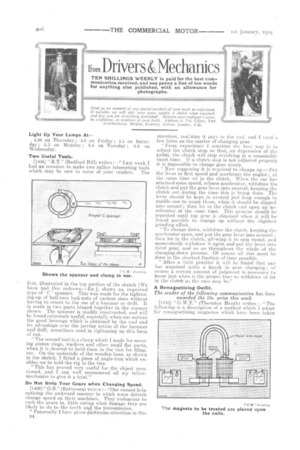

[1408] " R.T." (Bedford Hill) writes :—" Last week I had an occasion to make two rather interesting tools which may be new to sonic of your readers. The

first, illustrated in the top portion of the sketch [We have had this redrawn—En.], shows an improved type of 'C' spanner. This was made for the tightening-up of ball-race lock-nuts of various sizes without having to resort to the use of a hammer or drift. It is made in tWo parts lunged together in the manner shown. The spanner is readily constructed, and will be found extremely useful, especially when one notices the good leverage which is obtained by the tool and its advantage over the jarring action of the hammer and drift, sometimes used in tightening up this form of nut.

"The second tool is a clamp which I made for securing piston rings, washers and other small flat parts, when it is desired to hold them in the vice for filing, etc. On the underside of the wooden base, as shown in the sketch, I fitted a piece of angle-iron which enables me to hold the rig in the vice.

"This has -proved very useful for the object mentioned, and I can well recommend all my fellowmechanics to give it a trial."

Do Not Strip Your Gears when Changing Speed. •

[1409]" G.S." (Battersea) writs :—"One cannot help noticing the awkward manner in which some drivers change speed on their machines. They endeavour to rush the gears in, little caring what damage they are likely to do to the teeth ah4:the transmission. " Personally I have given particular attention in this n4

direction, realizing it pays in the end. and I send a few hints on the matter of changing gear.

" From experience I consider the best way is to adjust the clutch stop so that., on depiession of the pedal, the clutch will stop revolving in a reasonably short time. If a clutch stop is not adjusted properly it is impossible to change gear nicely.

" Now supposing it is required to change up :—Put the lever in first speed and accelerate the engine ; at the same time let in the clutch. When the car ha attained some speed, release accelerator, withdraw the clutch and put the gear lever into neutral, keeping the clutch out during the time this is being done. The lever should be kept in neutral just long enough to enable one to count three, when it should be slipped into second; then let. in the clutch and open up accelerator at the same time. This process should be repeated until top gear is obtained when it will be found possible to change up without the slightest grinding effect.

"To change down, withdraw the clutch, keeping the accelerator open, and put the gear lever into neutral ; then let in the clutch, allowing it to spin round, and momentarily withdraw it again and put the lever into third gear, and so on throughout the whole of the changing-down process. Of course all this must be done in the shortest fraction of time possible.

" After a little practice it will be found that one has acquired quite a knack in gear changing ; of course a certain amount of judgment is necessary to know just when is the proper time to withdraw or let in the clutch as the case may be."

A Demagnetizing Outfit.

The sender of the following communication has been awarded the 10s. prize this week.

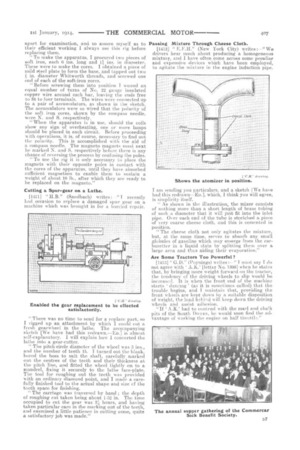

[MO] " (Thornton Heath) writes:—" The following is a description of a method which J. adopt for remagnetizing magnetos which have been taken

apart for examination, and to assure myself as to their efficient working I always use this rig before replacing them.

" To make the apparatus. I procured two pieces of soft iron, each 8 ins. long and 1 ins, in diameter. These were to make the cores. I obtained a, piece of mild s•teel plate to form the base, and tapped out two

in. diameter Whitworth threads, and screwed one end of each of the soft-iron cores.

"Before screwing them into position I wound an equal number of turns of N. 22 gauge insulated copper wire around each bar, leaving the ends free to fit to four terminals. The wires were connected up to a pair of accumulators, as shown in the sketch. The accumulators were so wired that. the polarity of the soft iron cores, shown by the compass needle, were N. and S. respectively.

"When the apparatus is in use, should the coils show any sign of overheating, one or more lamps should he placed in each circuit. Before proceeding with .operations, it is, of course, necessary to find out the polarity. This is accomplished with the aid of a compass needle. The magneto magnets must next be marked N. and S. respectively before there is any chance of reversing the process by confusing the poles.

" To use the rig it is only necessary to place the magnets with their opposite poles in contact with the. cores of the apparatus, until they have absorbed sufficient magnetism to enable them to sustain a weight of about 10 lb., after which they are ready to be replaced on the magneto."

Cutting a Spun-gear on a Lathe.

[1411] "KB." (Sandbach) writes:--" T recently had occasion to replace a damaged spur gear on a machine which was brought in for a hurried repair.

" There was no time to send for a replace part, so I rigged up an attachment by which I could cut a fresh gearwheel in the lathe. The accompanying sketch [We have had this redrawn—lin.] is almost self-explanatory. I will explain how I converted the lathe into a gear-cutter.

" The pitch-circle diameter of the wheel was 3 ins., and the number of teeth 15. I turned out the blank, bored the boss to suit the shaft, carefully marked out the centres of the teeth and their thickness at the pitch line, and. fitted the wheel tightly on to a mandrel, fixing it securely to the lathe face-plate. The tool for roughing out the teeth was provided with an ordinary diamond point, and I made a carefully finished tool to the actual shape and size cf the tooth space for finishing.

" The carriage was traversed by hand ; the depth of roughing cut taken being about 1-32 in. The time occupied to cut the gear was 2", hours, and having taken particular care in the marking out of the teeth, and exercised a little patience in cutting same, quite a satisfactory job was made." Passing Mixture Through Cheese Cloth.

[1412] " E.F.11." (New York City) writes:—"We drivers hear much about producing a homogeneous mixture, and I have often come across some peffuliar and expensive devices which have been employed, to agitate the mixture in the engine induction pipe.

am sending you particulars, and a sketch [We have had this redrawn—ED.], which. I think you will agree, is simplicity itself.

"As shown in the illustration, the mixer consists of nothing more than a short length of brass tubing or such a dia,rneter that it will just fit into the inlet pipe. Over each end of the tube is stretched a piece of very coarse cheese cloth, and this is cemented in position.

" The cheese cloth not only agitates the mixture, but, at the same •time, serves to absorb any small globules of gasoline which may emerge from the carburetter in a liquid state by splitting them over a large area and thus aiding their evaporation."

Are Some Tractors Too Powerful ?

[1413] " G.D." (Poynings) writes :---" T most say I do not agree with`AK. [letter No. 1399] when he states that, by bringing more weight forward on the tractor, the tendency of the driving wheels to slip would he ineyeascd. It is when the front end of the machine starts ' dancing ' (as it is sometimes called) that the trouble begins, and I maintain that, providing the front wheels are kept down by a suitable disposition of weight, the load bihind will keep down the driving wheels and assist adhesion.

"If A.K.' had to contend with the marl and chalk pits of the South Tiowns, he would soon find the advantage of working the engine on half throttle."