Popular Methods of

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

MOUNTING GOOD

LBODYWORK

December

I) 1933. 613

" OTJNTING " is a term which is used by the body builder to signify all the operations necessary to attach the body to the chassis. Its meaning extends to the fixing of the wings and steps and their stays, also various accessories, such as lamps, born and rear-view mirror. From the draughtsman's point of view, mounting is designing the body to suit the size and general arrangement of the chassis.

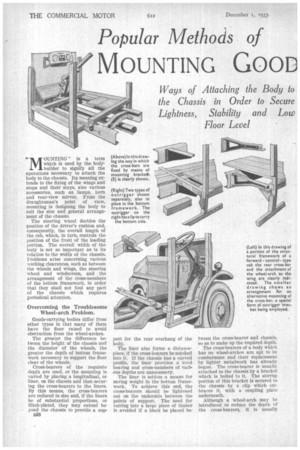

The steering wheel decides the position of the driver's cushion and, consequently, the overall length of the cab, which, in turn, controls the position of the front of the loading portion. The overall width of the body is not so important as is its relation to the width of the chassis. Problems arise concerning various working clearances, such as between the wheels and wings, the steering wheel and windscreen, and the arrangement of the cross-members of the bottom framework, in order that they shall not foul any part of the chassis which requires periodical attention.

Overcoming the Troublesome Wheel-arch Problem.

Goods-carrying bodies differ from other types in that many of them have the floor raised to avoid obstruction from the wheel-arches.

The greater the difference between the height of the chassis and the diameter of the wheels, the greater the depth of bottom framework necessary to support the floor clear of the wheels.

Cross-bearers of the requisite depth are used, or the mounting is varied by placing a longitudinal, or liner, on the chassis and then securing the cross-bearers to the liners. By this means, the cross-bearers are reduced in size and, if the liners be of substantial proportions, or hitch-plated, they may extend beyond the chassis to provide a sup port for the rear overhang of the body.

The liner also forms a distancepiece, if the cross-bearers be notched into it. If the chassis has a curved profile, the liner provides a level bearing and cross-members of varl. ous depths are unnecessary.

The liner is seldom a means for saving weight in the bottom framework. To achieve this end, the cross-bearers should be lightened out on the underside between the points of support. The need for cutting into a large piece of timber is avoided if a block be placed be

tween the cross-bearer and chassis, so as to make up the required depth.

The cross-bearers of a body which has no wheel-arches are apt to be cumbersome and their replacement by lighter metalwork has already begun. The cross-bearer is usually attached to the chassis by a bracket which is bolted to it. The stirrup portion of this bracket is secured to the chassis by a clip which embraces it, with a coupling plate underneath.

Although a wheel-arch may be introduced to reduce the depth of the cross-bearers, it is usually adopted to obtain a low floor level. Shallow cross-bearers are necessary so that the floor is close to the chassis and weight is saved.

With this type of bottom framework the oak cross-bars may be stiff enough to support the body without any flitch-plating, especially if the bottom side be wide and rests directly on the chassis. This kind

of bottom side is usually heavy and weight is saved by using one of smaller section. reinforcing the bottom corners of the body by means of a bracket.

These bracket plates should not cause an obstruction above the floor. For this reason the extension of the sides of the body below the top of the chassis is a constructional advantage, because the feet of the pillars below the floor may he used for fixing the bracket plate.

Cross-bars are drilled and bolted directly to the chassis, although this may be avoided by substituting clips, as already described. Drilling of the chassis by the bodybuilder is also unnecessary if mounting brackets be provided.

There is some difficulty in arranging these brackets so that they shall be in the correct position for the cross-bars of any type of body which may be mounted. There are, however, two cross-bars which have a fairly definite location, namely, the front one, which avoids the gearbox cover, and the other, which is at the base of the forward bulkhead.

A development of the mounting bracket is the outrigger, which, up to the present, is chiefly to be found on chassis designed for passenger bodywork. The outrigger, like the bracket, must be in the appropriate position.

In effect, it increases the width of the chassis, so that it is as wide as the bottom of the body. It is suitable for use in conjunction with light cross-bars, but with a stout floor it is possible to dispense with them. The outrigger may be a simple pressing, or elaborated to provide a bearing for the bottom side.

With the forward-control cab, the bottom frame must be modified, because the engine and its cover prevent the use of continuous crossbars. One may usually be set out immediately behind the engine and, if there be a rear dash plate, a'good fixing is available for the back of the cab.

Some chassis have a metal floor plate which determines the position of the bottom side, whilst in most instances the front wing forms the foundation of the wheel-arch framework. The wing stays should, therefore, be designed for their dual purpose of an attachment for the wing and part of the bottom framework of the cab.

Extended Skirt Panels and Chassis Accessibility.

When the sides of the body are below the chassis, it is difficult sometimes to obtain access to the brake gear and other parts. In some instances the skirt panelling is hinged, or made detachable as a whole, or in sections. If the rigidity of the feet of the side pillars is to be preserved, the movable panel should have an independent framework, so that it is like a door. The feet of the side pillars are joined by a rail.

This may be interrupted to provide a skirt-panel opening, with full access to the chassis, or the skirt rail is continuous and the panel opens above it. If the body has a lifeguard with stays fastened to the feet of the pillars, the lifeguard may form a stiffener to the body framework.

To increase the life of the bodywork it should have some degree or flexibility in its mounting. The cab should be mounted independently of the loading portion, or if these two parts be not separated there should be no rigid connection between the cab and the dashboard..