THE NEW CI

Page 12

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

(SON CHASSIS.

Coke-fired Boiler : Duplex Tandem Conn

T Engine : Transmission Including Gearbox.

IN AN ARTICLE which was published in our issue of the 28th February last dealing with certain activities of the National Steam Omnibus Co., and particularly in reference to a conversion of some existing buses, previously run on paraffin as a fuel, to coke-firing, a reference was briefly made to an impending new departure of much greater moment, to wit, the approaching completion of an entirely new coke-fired chassis, which-, as we were then allowed to state, would embody many new, striking and useful .features. What was then only to /be, now is. We have had the gratification of a trial run on the new chassis, which behaved extremely well. The minutest detaila of its construction and the reason for their being have been divulged to us, and we once again have the pleasure of sharing with °Ur readers our, as usual, prior knowledge of important new developments. In our previous article we mentioned the decision to fit a gearbox, a component which has Thitherto been regarded as foreign to the steam chassis. The reasons ,whicli led to this decision, the advantages which it gave—particularly in respect of the elimination of the complicated and continually wearing though little-used engine reversing gear—were then discussedby us. It was also pointed out that an ordinary friction clutch was incorporated, and since the provision of these two components called for a clutch pedal and change-sp-.!.ed lever, the next step of arranging the control on lines precisely similar to those of a petrol chassis follows naturally. In view of the superiority, as 'regards numbers, of the petroldriven type, the expediency of this arrangement becomes axiomatic. The control of the new Clarkson steamer, then, is identical with a petrol vehicle, -with the exception of the ignition control lever, which is, of course, absent. There are clutch and brake pedals in the usual positions, change-speed lever, side brake lever, and an accelerator pedal which acts directly on the engin throttle :valve. A small by-pass, regulated by a hand wheel, provides far the admission of a small volume 'of steam with the accelerator pedal in the closed position, thus providing for the engine to tick over slowly when the vehicle is at a standstill. Equipped with a clutch and gearbox, -the chassis .becomes, from engine rearwards, a facsimile of a petrol vehicle, and we can now, therefore, confine ourselves to a consideration of the Clarkson power unit only, consisting of 'boiler, engine and condenser. Indeed, there is another reason why attention should be focussed on this portion of the vehicle alone. The unit may, with slight frame modifications only, be fitted -to any type of petrol chassis. There is a shortage of petrol and a plenitude of coke. The moral is obvious, and Mr. Clarkson's immediate intention, we understand, is to lay himself out to the production of these units, which can then be fitted to chassis with frames of any or all types elsewhere. •

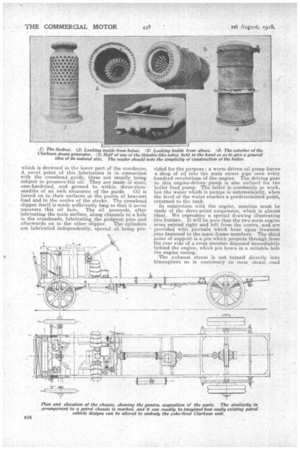

A detailed description naturally follows the proper sequence from the fire through boiler and engine to condenser, and commences with the steam generator. Although this has already been described in :brief in these columns (in January last), its importance is such that a more detailed reference is now permissible. It consists, in the main, of an inner and outer cylinder : the inner one contains the fire and the central tubular fuel shoot. It is perforated, above the waist line, with a number of holes into which are forced thimble-shaped cylinders, which correspond to water tubes. The whole of the combustion space below the level of the coke shoot and the water tubes is, in the first place, filled with fuel, one filling being sufficient for a run of 12 or 15 miles. The burnt gases emerge near the top of the boiler and are carried down a pair of flues, one at each side, to steam. operated injectors, which project these gases along two pipes running almost the full length of the chassis and below it. The steam jets within these injectors provide the only draught to the boiler. They are ingeniously and automatically controlled according to the steam pressure, so that they only operate when there is a demand for steam._ The strength and heat of the fire is therefore controlled strictly according to requirements. The spaces between the fire bars are wide, a minimum of in. being allowed between each pair, so that the ash is free to fall as it is formed. Additional width of fire-bar space is essential in any case on account of the greater air supply which is called for by coke. The draught through the fire is only in exceptional circumstances a high one, so that the ash which is not immediately dropped through the grate does not have a' chance to become, fused and the formation of clinker is therefore obviated. Once lit and filled with fuel, the boiler will work without any attention whatever until the fuel itself is burning low ; it can then. be filled. up once more and will proceed still without any other attention than this. in the evening, or when it is desired to draw the fire, all that is necessary is to release two levers Which appear on our illustration, one on each side of the bonnet ; these drop the fire bars and their carrier to within 6 ins. or so of the ground, and the whole of the fire can readily and rapidly be removed and the bars cleaned or scraped if necessary. The space between the inner and outer cylinders is for water and steam. Water is fed at the waist of the 'boiler, but does not impinge directly upon its inner shell. In between the inner and outer eases and suspended there is a thin cylinder of steel. This

acts as a shield against the incoming stream of cold-water, and, as a result of natural circulation, the cold water travels to the bottom of the boiler and underneath this suspended cylinder, then upwards inside it and between it and the inner casing. The beneficial results from this arrangement, in addi tion to the circulation described, are two-f old. There is no local cooling of the inner shell owing to the direct contact from this incoming stream. The deposit of lime and impurities which. otherwise would spread over the outer surface of the combustion chamber with additional strata round and about the point of entry of the water is apparently laid upon the suspended cylinder : owing to the lightness of the latter and its constant vibration, there is no tendency to form, scale, the deposit is shaken to the bottom of the boiler in the form of a fine powder, whence it is easily and thoroughly removed by means of the blow-off tap, which is arrangedBO that it draws the water from the boiler with a. circular motion. Boilers have

been examined after many months' use without there being any sign of corrosion or formation of scale from this cause. txperiments with glass tubes have also gone to show that there is a constant circulation of water inside the thimble-like tubes, and it is a notable fact that they do not harbour deposit. One obvious advantage of the thimble typo of water tube is that no deleterious effects arelikely to •

ensue from expansion and contraction, since they are free to move endwise, and as regards their loosening, it has been found necessary to insert these tubes with only a light hydraulic pressure, the pressure of

the steam and water tending always to tighten them in place. The im portance of expansion, too, has also been carefully studied in Conjunction with the design of the boiler 'shell, as will readily he realized by reference to our illustration. Each of. the two portions is forged in the solid and turned inside and out. it is probably the only steam generator of its size which is so treated. The two parts are coupled by bolts, and the top and bottom are so designed with free bends so that any conceivable amount of expansion can be cared for without straining either material or fastening. An important advan tage of the turned boiler shell is that the material can he left a little thicker here and there in order to provide for drilling, etc., and this

point has been taken advantage of in the case of the Clarkson generator. One more point before turning from the boiler to the other parts of the mechanism. Owing to the use of a condenser the vehicle can travel from 30 to 60 miles upon one charge of water ; there is, therefore, no need to call for water indiscriminately, and it can easily be arranged to obtain supplies of clean water within these limits of travel.

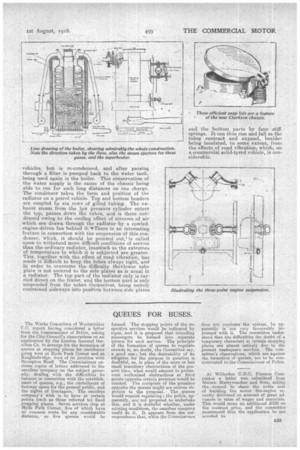

The boiler is placed beneath a bennet. Immediately behind it is the steel cowl dash, and behind and under this is the V-type duplex tandem-come -pound engine. There are four cylinders, two high" pressure and two low. One high and one low pressure cylinder act together on one connecting rod; their axes are in line, the high pressure being the upper one.. The other pair of cylinders are similarly disposed with their common axes at right angles to that of the first pair, the connecting rod having a divided big-end and acting upon the same crank. The

disposition of the cylinders is after the manner of what is well known to petrol-engine enthusiasts as the " 90 degrees T."

The valve gear for all four cylinders is operated by one single eccentric, the high pressure cylinder being fitted with piston valves, which are on the same spindles as the slide valves which control the steam supply to the low pressure cylinders. A minimum of moving parts is therefore employed. The 00-degrees engine is noted for its almost perfect balance. The double-acting steam engine gives an even torque, and

the result is an extreme smoothness of running and absence of vibration. The high-pressure cylinder is 3 insdiameter ; the low pressure 5 ins., and the stroke 3 ins., and the engine develops 30 h.p., its normal rotational speed being 600 r.p.m.

Lubrication of the more mechanical parts of the engine, the hearings, connecting rods, crosshead guides, etc., is under pressure from a gear pump

which is drowned in the lower part of the crankcase. A. novel point of this lubrication is in connection with the crosshead guide, these not usually being subject to pressure-fed oil. They are made of steel, case-hardened, and ground to within three-thou

sandths of an inch clearance of the guide. Oil is forced on to their surfaces at the points of heaviest load and in the centre of the stroke. The crosshead slipper itself is made sufficiently long so that it never uncovers this oil hole. The oil proceeds, after lubricating the main surface, along channels to a hole in the crossheads, lubricating the gudgeon pins and afterwards on to the other slipper. The cylinders are lubricated independently, special oil being pro

vided for the purpose ; a worm-driven oil pump forces a drop of oil into the main steam pipe once evbry hundred revolutions of the engine. The driving gear to this engine-driven pump Is also utilized for the boiler feed pump. The latter is constantly at work, but the water which it pumps is automatically, when the level of the water reaches a predetermined point, returned to the tank.

In connection with the engine, mention muat be made of the three-point suspension, which is almost ideal. We reproduce a special drawing illustrating this feature. It will be seen that the two main engine arms extend right and left from the centre, and are provided with journals 'which bear upon trunnion pins fastened to the main frame members. The third point of support is a pin which projects through from the rear side of a cross member disposed immediately behind the engine, which pin bears in a suitable hole the engine casing.

The exhaust steam is not turned directly into htmosphere as is customary on most steam road

vehicles, but is re-condensed, and after passing through a filter is pumped back to the water tank, being used again in the boiler. This conservation of the water supply is the cause of the chassis being able to run for such long distances On one charge. The condenser takes the form and position of the radiator on a petrol vehicle. Top and bottom headers are coupled by six rows of gilled tubing. The 'exhaust steam from the low pressure cylinder enters the top, paSses down the tubes, and is there condensed owing to the cooling effect of streams of air which are drawn through the radiator by a cowledengine-driven fan 'behind it.I.There is an interesting feature in connection with the suspension of this condenser, which, it should be pointed out,( is called upon to withstand more difficult conditions of service than the ordinary radiator, inasmuch as the extremes of temperature to which it is subjected are greater. This, together with the effect of road vibration, has made it difficult. to keep the tubes always tight, and in order to overcome the difficulty the ilovver tube plate is not secured to the side plates as is usual in a radiator. The top part of the radiator only is carried direct on the frame and the bottom part is only suspended from the tulics themselves, being merely restrained sideways into position between side plates

and the 'bottom parts by four stiff springs. It cart thus rise and fall as the tube ki contract and expand, beside_s being insulated, to some extent, from the effects of road .vibration, which, on a commercial solid-tyred vehicle, is eonsidetable.