HINTS ON MAINTENANCE.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen, and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to tho particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, dealing with letters from our driver and mechanic readers. Communications should be addressed to "The Editor, The Commercial Motor. 7-15, Rosebery Avenue, London, E.C.1."

265.—Removing Ridges on Brake Drums.

A difficulty often occurs with the removal of rear wheels of heavy lorries due to the brake shoes having worn into the rear brake drums leaving a ridge on the outer rim which prevents the withdrawal of the wheel, due to the brake shoes fouling. In the event of the shoes requiring relining, this ridge obviates the correct size lining being fitted. The difficulty was overcome on a 5-ton Karrier by jacking. up both rear wheels and building up packing under the centre of the rear axle for safety. The engine was put into reverse gear and kept slowly running. One wheel was lightly skotched to prevent loss of motion through the differential.

A turning tool with a broad base was made from an old file.

Having pulled on the brake until it almost touched tho brake drum, the ridge was turned off, using the top of the brake shoe as a'rest.

The work on both wheels took about two hours, and resulted in the wheels being removed without difficulty, whilst in relining the brake shoes i-in. Ferodo instead of *-in. was used.

266.—Improving the Water Pump on Dennis Engine.

In our Hint No. 251 we described a method for preventing water leakage from the pump on a Dennis engine. We have received particulars of another method of effecting a cure, which is said to be an improvement on the fitting of a new fibre washer.

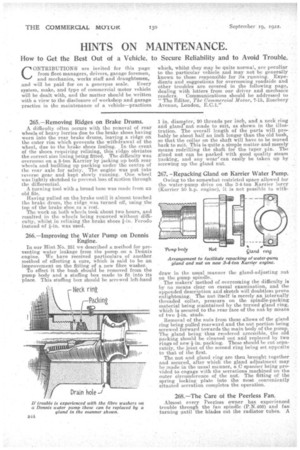

To effect it the bush should be removed from the pump body and a stuffing box made to fit into its place. This stuffing box should be screwed left-hand

1 in. diameter, 20 threads per inch, and a neck ring and gland nut made to suit, as shown in the illustration. The overall length of the parts will probably be about half an inch longer than the old bush, so that the collar on the shaft will have to be moved back to suit. This is quite a simple matter And merely means redrilling the shaft for the taper pin, The gland nut can be packed with good quality steam packing, and any wear' can easily be taken up by screwing up the gland nut.

267. —Repacking Gland on Karrier Water Pump.

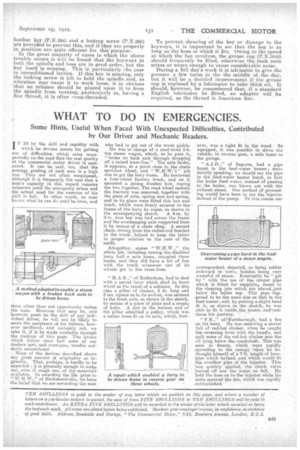

Owing to the somewhat restricted space allowed for the water-pump drive on the 3-4-ton Karrier lorry (Karrier 50 h.p. engine), it is not possible to with

draw in the usual manner the gland-adjusting nut on the pump spindle. . The makers' method of overcorning the difficulty is by no means clear on casual examination, and the appended description and sketch will doubtless prove enlightening. The nut itself is merely an internally threaded collar, pressure on the spindle-packing material being maintained by the turned gland ring, which is secured to the rear face of the nut by means of two 1-in. studs.

Removal of the nuts from these allows .of the gland ring being pulled rearward and the nut portion being screwed forward towards the main body of the pump. The gland beingthus rendered accessible, the old packing should be cleaned Mit arid replaced by two rings of new i-in. packing. These should he cut separately, the joint of the second ring being set opposite to that of the first.

The nut and gland ring are then brought together and secured, after which the gland adjustment may be made in the usual manner, a C spanner being provided to engage with the serrations machined on the outer circumference of the nut. The fitting of the spring locking plate into the an'ost conveniently situated serration completes the operation. feather key (P.N.394) and a locking screw (P.N.395) are provided to prevent this, and if-they are properly in position are quite efficient for this purpose. In the great majority of cases in which the above trouble occurs it will be found that the keyways in both the spindle and boss are in good order, but the key itself is missing. This is particularly the case in reconditioned lorries. If this key is missing, only the locking screw is left to hold the spindle and, as vibration may cause it to work loose, it is obvious that no reliance should be placed upon it to keep the spindle from turning, particularly as, having a fine thread, it is often eross-thrcaded.

To prevent shearing of the key or damage to the keyways, it is important to see that the key is as long as the boss in which it fits. Owing to the speed at which the fan revolves, the grease cup (P.N.3042) should .frequently be filled, otherwise the _bush soon seizes or wears enough to cause considerable noise.

During a full day's work it is advisable to give the greaser a few turns in the the middle of the day, but it will be a decided improvement, if the grease cup is replaced by a lubricator to take thick oil. It should, however, be remembered that, if a standard English lubricator be fitted, an adapter will be required, as the thread is American fine_.