PROGRESS IN PISTON DESIGN.

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the New Zephyr, with Aluminium Head and Steel Skirt.

ONE of the greatest factors in the O running and maintenance of a petrol engine is the type of piston employed. On their weight and balance depend to a most important degree the smooth running and maximum speed, whilst the material or materials employed exercise a great effect on the wearing life of the cylinder bores.

In the commercial vehicle, particu-• larly in the eases of the lighter classes and passenger models, engine speeds have inereased•to such an extent that they 'are now comparable with these of the power units in private cars, ,consequendy everything possible most be done to decrease the weight of the reciprocating parts and to permit high piston speeds without undue wear or expenditure of lubricants.

The ordinary aluminium or aluminium-alloy piston, whilst being somewhat lighter than that made of castiron, does not permit so much reduction as is desirable, because of the extra ; thickness of metal which is necessary to compeusate for its coMparative weak c30 •

nes& It also offers certain other objections, such as excessive clearance when cold, which results in piston slap, and extra wear of the cylinder bore through collecting and holding minute particles of harder metal and thus-acting as a lap. In scene of the aluminium alloys, however, such hardness is obtained as to reduce this grinding action, so that it becomes almost negligible.

any pistons have been designed to overcome these faults, and one of the most promising, in our view, is the type A/S Zephyr, patented by Mr. E. Talbot,

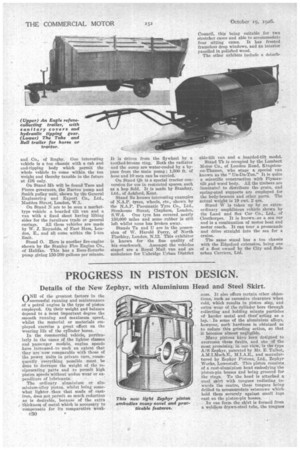

and manufactured by Zephyr Pistons, Ltd., Zephyr Works, Lowestoft. This piston consists of a cast-aluminium head embodying the piston-pin bosses and being grooved for the line's. To the head is attached a steel skirt with tongues radiating towards the centre, these tongues being drilled to accommodate 'setscrews which bold them securely against small lugs cast on the piston-pin bosses.

In one form the skirt is formed from a weldless drawn-steel tube, the tongues being cut from the tube itself and folded inwards. This construction /ends itself admirably to mass production. In, another form—that illustrated— the skirt is formed from two cup-Shaped pressings of sheet steel placed back to back, the retaining setscrews passing through the tongues of each portion. One of the chief reasons for the success of the new Zephyr piston is that the upper part of the skirt is a clearance fit on the aluminium head, consequently it is entirely unaffected by expansion or contraction of the head.

The weight is less than that of an all • aluminium piston of corresponding size, clue to the thinner skirt permitted by the employment of high-tensile steel. Incorporated with the piston are two other patented devices which, in themselves, are well worthy of consideration. The first is the Zephoil ring, which consists of two thin steel rings, the upper plain and the lower waved, so that, when assembled in the special groove, the waved ring keeps the other in con

tact with the upper face of the groove, thus farming a seal against tfie passing of too much oil. The action of these oilsaving rings is not that of a scraper, as they exercise practically no spring against the cylinder ; in fact, a piston fitted with one Zephoil ring only will float down a vertical cylinder by its own weight alone.

The second device is provided to prevent the ends of the piston pin from coming into contact with the cylinder walls should the pin tend to move sideways It consists of a spring tongue which is fitted between the steel skirt and the end of the pis-ten-pin boss. The lower end of this tongue forms a bow, the extreme tip of which is straightened and located in a channel formed at the foot of the piston skirt. Two of these tongues are, of course, required.

The use of the tongues obviates the need for any other method of fixing the pin, such as by setscrews or buttons.

Zephyr pistons of this type have been supplied for engines from 55 mm. bore up to 127 mm. bore, and where the quan,tities-are sufficient they are competitive with either cast-iron or aluminium pistons.

They have been subjected to extremely severe tests, some by intent and others by chance. In the latter category one is worth especial mention. A set of Zephyr pistons was fitted to an engine having steel cylinders, and owing to a failure in the lubricating system two of the six cylinders were practically starved of oil, and, despite this, the pistons Tall for some time at a vehicle speed of 60 m.p.h. Upon examination it was found that one of the cylinders had warped 11mm. out of round, yet no signs of slackness could be observed in the piston setscrews and the pistons were quite serviceable.

Remarkable economies have been effected in the oil consumption of many engines, the mileage per gallon having:in one instance been raised from 460 to over 5,000, and in another from 400 to 1,600.