How to Keep Your Lorry Fit.—IX.

Page 5

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

This Week's Article is Devoted to a Consideration of the 50-cwt. Star Chassis.

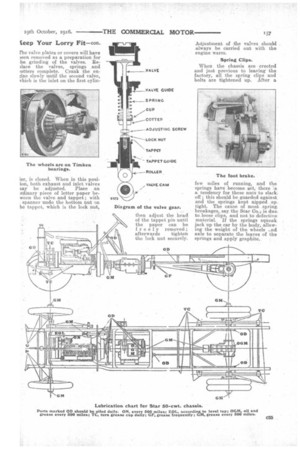

The Star Engineering Co., Ltd., makers of that popular and reliable chassis for 50 cwt. loads, known as the " Star," claim that one of the most important factors in the eccessful running of the vehicle, and one which is too often neglected, is the lubrication of its working parts. In the neat little handbook entitled Instructions on the Care and Management 3f Star Vehicles," the matter of lubrication is in consequence given preference both in respect of place and quantity.

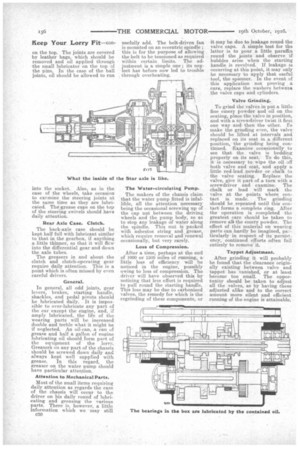

Engine Lubrication.

The engine lubrication is by pump, the oil being forced under pressure to all the crankshaft and connecting rod big-end bearings. The oil is carried in a reservoir or sump in the bottom, half of the crank chamber. The pump is on a level with the end of the camshaft, by which it is driven, and draws the oil from this sump, forcing it through passages cast in the metal of the crankcase to the main bearings of the crankshaft. Here a portion of it is detached and spread over the width of the bearings by means of grooves. The remainder is forced through a hole in the journal through the centre of the crankshaft and passes thence along suitably-drilled holes to the big-end bearings. Here a further portion is distributed over these journals, and that lubricant still remaining exudes from the ends of the brasses, and is thrown up in the cylinder walls and gudgeon pins. Any surplus oil falls back on to a large gauze diaphragm, through which it drains into the sump and is then again taken up by the pump and used. Provided that the correct amount of oil is kept in the crank chamber, and that the pump is. working correctly and keeping the oil travelling, then it may be taken for granted that the lubrication of the internal moving parts of the engine is proceeding satisfactorily. An

indication as to the amount of oil in the chamber is afforded by a tap on the side of the crank chamber, which commences to overflow when the correct supply of oil is exceeded. An indicator on the dashboard, either in the form of a. gauge showing the pressure in the oil pipes in lb. per sq. in., or of the type in which a plunger is forced out when the oil is circulating, serves to show when the pump is functioning correctly. If the pressure gauge drops to zero or the plunger ceases to be forced out, it is a clear indication that the oil is not circulating.

The Gearbox.

Now, as to the gearbox. This should normally be about half full of lubricant, the best mixture for the purpose being thick yellow grease and machinery or gear Dil in equal proportions ; it should, however, be sufficiently thin to flow through all the bearings. The box

should be examined about every 500 miles to see that it contains the proper amount of lubricant, and when cleaning out the box and adding fresh grease, great care should be taken to see that no loose nuts or other foreign matter is allowed to enter the box, as if this does occur, the result will in all probability be serious damage to the gears or bearings. In the ordinary way, the gearbox bearings receive sufficient oil from the interior of the box and do not need any further attention. Whenever an examination is being made, however, it is advisable just to glance at these to be sure that the oil is finding its way there.

Wheel Bearings.

The wheel bearings should also be lubricated about every 500 miles. This operation is effected by removing the axle caps, filling with oil, and rescrewing into place. Use engine oil, as it is thick enough to remain in the bearings and does not leak out. When preparing to lubricate -the axles, the opportunity is a useful one to test the wheels for play.

Brake Joints.

All the moll pins and joints on the brakes should be oiled daily, thus keeping the brakes free and easy to apply, preventingthem from getting rusty and sticking on when they should be off.

Steering Gear.

At the same time as the wheel bearings are being lubricated, the steering should receive like attention. The steering box is supplied with oil by removing the small plug on the top. The joints are covered by leather bags, which should be removed and oil applied through the small lubricator on the top of the pins. In the case of the ball joints, oil should be allowed to run

into the socket. Also, as in the case of the wheels, take occasion to exemine the steering joints at the same time as they are lubricated. Thergrease cups on the top of the steering swivels should have daily attention.

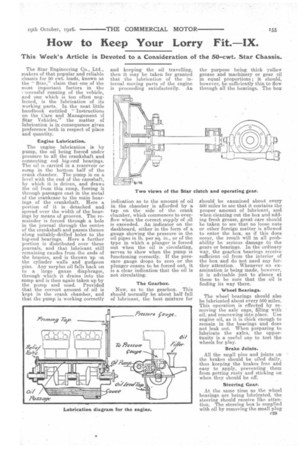

Rear Axle Case. Clutch.

The back-axle case should be kept half full with lubricant similar to that in the gearbox, if anything a little thinner, so that it. will flew into the differential gear and down the axle tubes.

The greasers in and about the clutch and clutch-operating gear require daily attention. This is a point which is often missed by even careful drivers.

General.

In general, all odd joints, gear levers, brakes, starting handle, shackles, and pedal pivots should be lubricated daily. It is impos• sible to over-lubricate any part of the ear except the engine, and, if amply lubricated, the life of the wearing parts will be increased double and treble what it might be if neglected. An oil-can, a can of grease and half a gallon of engine lubricating oil should .form part of the eqeipment of the lorry. Greaserson any part of the chassis should be screwed down daily and always kept well supplied with grease. In this regard, the greaser on the water pump should have particular attention.

Attention to Mechanical Parts.

Most. of the small items requiring daily attention as regards the care of . the chassis will occur to the driver on his daily round of lubricating and greasing the various parts. There is, however, a little information which we may still C30 usefully add. The belt-driven fan. is mounted on an eccentric spindle ; this is for the purpose of allowing the belt to be tensioned as required within certain limits. The adjustment is a simple one ; its neglect has before now led to trouble through overheating.

The Water-circulating Pump.

The makers of the chassis claim that the water pump fitted is infallible, all the attention necessary being the occasional screwing np. of the cap nut between the driving wheels and the pump body, so as to stop any leakage of water along the spindle. This nut is packed with asbestos string and grease, which require removal and renewal occasionally, but very rarely.

Loss of Compression.

After a time, perhaps at the end of 1000 or MO miles of running, a little loss of efficiency will be noticed in the engine, possibly owing to loss of compression. The driver will have observed this by noticing that less effort is required to pull round the starting handle. This loss may be due to carbonized valves, the remedy for which is the regrinding of these components, or

it may be due to leakage round the valve caps. A simple test for the latter is to pour a little paraffin round the joints and observe if bubbles arise when the starting handle is revolved. If leakage le occurring at this point, it may only be necessary to apply that useful tool, the spanner. In the event of this application not proving a cure, replace the washers betweta the valve caps and cylinders.

Valve Grinding.

To grind the valves in put a little fine emery powder and oil on the seating, place the valve in position, and with a screwdriver twist it first one way and then the other. re make the grinding even, the valve should be lifted at intervals and replaced on its seat in a. different position,. the grinding being continued. Examine occasionally to see that the. valve is bedding properly on its seat. To do this, it is necessary to wipe the oil off both valve and seat, and apply a little red-lead ponder or chalk to the valve seating. Replace the valve, give it part of a turn with a screwdriver and examine. The chalk or lead will mark the valve at the points where contact is made. The grinding should be repeated until this contact forms a complete ring. After the operation is completed the greatest care should be taken to remove all the emery powder. The effect of this material on wearing parts can hardly be imagined, particularly in respect of its persistency, continued efforts :often fail entirely to remove it.

Tappet Adjustment.

After grinding it will probably be found that the clearance originally existing between valve and tappet has vanished, or at least become too small. The opportunity should be taken to adjust all the valves, as by having these adjusted alike and to the correct amount more silent and efficient running of the engine is attainable. rhe valve plates or covers will have )een removed as a preparation for ,he grinding of the valves. Re)lace the valves, springs and !otters complete. Crank the encine slowly until the second valve, vhich is the inlet On the first eylin ter, is closed. When in this posiion, both exhaust and inlet valves say be adjusted. Place an xdinary piece of letter paper beween the valve and tappet ; with , spanner undo the bottom nut en he tappet, which is the lock nut, then adjust the head of the tappet pin until the paper can be freely removed ; afterwards tighten the lock nut securely. Adjustment of the valves should always be carried out with the engine warm.

Spring Clips.

When the chassis are erected and just previous to leaving the factory, all the spring clips and bolts are tightened up. After a few miles of running, and the springs have become set, there ;2, a tendency for these nuts to slack. off; this should be guarded against and the springs kept nipped up. tight. The cause of most spring breakages, say the Star Co.; is due. to loose clips, and not to defective material. If the springs squeak jack .up the car by the body, allowing the weight of the wheels —nd axle to separate the leaves of the springs and apply graphite.