For Drivers, Mechanics, and Foremen.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

We revive this popular "CM." feature in connection with our "Keep Your Lorry Fit" Series, and offer a prize of ONE GUINEA for the best communication concerning any chassis to which reference has been made in that series.

Other letters on subjects of interest will be paid for on publication at the rate of One Penny 4 Line, and failing any award of the above prize, TEN SHILLINGS will be paid for the best letter published each week. Mention your employer's name, in confidence, as evidence of good faith. Address D., M. and F., "The Commercial Motor," 7-15, Rosebery Avenue, London, B.C.

ailboard Fittings.

The sender of the following two letters has been awarded the 10s. prize this week.

[1674] " B.O.B." (Canada) writes :—" Tailboard fitings are not always satisfactory. One of the best hat I know is that fitted on Albion wagons. It ould be adopted by other makers with advantage. he sketch which I enclose [We have had this re.rawn.—En.] is made from memory, but I think :t rill be sufficient to illustrate the idea."

Ion -skids. .

[1675] " B.O.B." (Canada) writes :—" Satisfactory ion-skids for heavy vehicles are rare. Those which ire most effective are of the chain type similar to the ?arsons, or like the Sheppee, or flat one made by 3artles, which are applicable to twin solid-tired

wheels, and consist of a chain which is placed in the !groove between the two tires and which carries at intervals cross-bars to afford a grip on the road. "My own idea is to use several short pieces of chain to attach lengths of channel iron to the wheel. As will be gathered from the sketch [We have had this redrawn.—En.], the channel iron is placed with its back to the rubber tires and the chain wraps round the rim of the wheel, the ends being fastened by means of a bolt."

Re-assembling a Sleeve-valve Engine: A Wrinkle.

[1676] " A.H.H." alandaff) writes : —" When reerecting sleeve valve engines of both the single and double sleeve type, after fixing the crankshaft in a certain position it will be found possible to pass the piston and connecting rod through the hole in the crankcase and afterwards to get it into place in the cylinder.

"The difficulty about this method of replacement is that ofA persuading the rings to enter the cylinder bore. For this purpose I have had a collar made, the interior of which is a sliding fit over the rings, which is bell-mouthed at the bottom so that it may easily be pushed over the rings, and which is tapered on its external diameter at the top, so as to enter the bottom end of the sleeve.

"With the pistons and ring in position underneath the cylinder, it is then easy to push the piston through the sleeve, when the rings will automatically enter the cylinder without further difficulty."

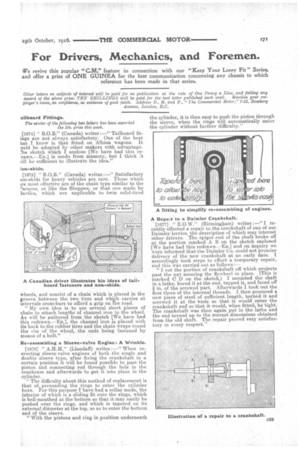

A Repair to a Daimler Crankshaft.

[1677] " E.O.W." (Birmingham) writes :—" I recently effected a repair to the crankshaft of one of our Daimler lorries, the description of which may interest other drivers. The spigot end of the shaft broke off at the portion marked A B on the sketch enclosed [We have had this redrawn.—ED.] and on inquiry we were informed that the Daimler Co. could not promise delivery of the new crankshaft at an early date. I accordingly took steps to effect a temporary repair, and this was carried out as follows :—

" I cut the portion of crankshaft off which projects past the nut securing the flywheel in place. (This is marked C D an the sketch.) I mounted the shaft in a lathe, bored it at the end, tapped it, and faced off

in. of the screwed part. Afterwards I took out the first three of the internal threads. I then procured a new piece of steel of sufficient length, turned it and screwed it at the 'ends so that it would enter the crankshaft and' so that it would, when fitted, be tight. The crankshaft was then again put in the lathe and the end turned up to the correct dimensions obtained from the old shaft. The repair proved very satisfactory in every respect.'