The " Practical " Force-feed Oil Pump.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

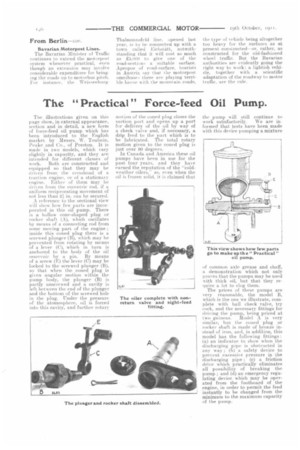

The illustrations given on tins page show, in external appearance, section and in detail, a new form of force-feed oil pump which has been introduced to the English market by Messrs. W. Toulmin, Peake and Co., of Preston. It is made in two models, which vary slightly in capacity, and they are intentled for different classes of work. Both are constructed and equipped so that they may be driven from the crosshead of a. traction engine, or of a stationary engine. Either of them may be al\ en from the eccentric rod, if a uniform reciprocating movement of not less than 2"-.in. can be secured.

A reference to the sectional view will show how few parts are incorporated in this oilpump. There is a hollow cone-shaped plug or rocker shaft (A), which oscillates by means of a connecting rod from sonic moving part of the engine ; inside this coned plug there is a screwed plunger (B), which may be prevented from rotating by means of a lever (C), which in turn is anchored to the body of the oil reservoir by a. pin. By means of a screw (E) the lever (C) may be locked to the screwed plunger (B), so that when the coned plug is given angular motion within the pump body, the plunger (B) is partly unscrewed and a cavity is left between the end of the plunger and the bottom of the screwed hole in the plug. Under the pressure of theatomosphere, oil is forced into this cavity, and further rotary

motion of the coned plug closes the suction port and opens up a port for delivery of the oil by way of a check valve and, if necessary, a drip feed to the _part which is to be lubricated. The total rotary motion given to the coned plug is just over 90 degrees.

In Canada and America these oil pumps have been in use for the past four years, and they have earned the reputation of the "coldweather oilers," as. even when the oil is frozen solid, it is claimed that the pump will still continue to

work satisfactorily. We are informed that tests have been made with this device pumping a mixture

of common axle grease and chaff, a demonstration which not only proves that the pumps may be used with thick oil, but that they require a lot to clog them.

The prices of these pumps are very reasonable, the model B, which is the one we illustrate, complete with ball check valve, try cock, and the necessary fittings for driving the pump, being priced at two guineas. Model A is very similar, but the coned plug or rocker shaft is made of bronze instead of iron, and, in addition, this model has the following fittings : (a) an indicator to show when the discharging pipe is obstructed in any way ; (b) a safety device to prevent excessive pressure in the discharging pipe ; (c) a friction drive which practically eliminates all possibility of breaking the pump ; and (d) an emergency regulating device which may be operated from the footboard of the engine, in order to permit the feed instantly to be changed from the minimum to the maximum capacity of the pump.