Abridgments of Interesting Patent Specifications.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

No. 24,376, dated November loth, 1904. —Clutch.—Clifton.—On the shaft (al) is a wheel (a) carrying cylinders (b). Each cylinder has a piston if), and a passage way (c) connects both ends of the cylinder. The passage (e) is controlled by a valve (e). The connecting rods (h) of the pistons engage a crank (i) on the shaft (k), which is to be driven, and operating levers connect the valves (e) with a ring (1) free to slide on this shaft. The cylinders are filled with oil, and, assuming the valves (e) to be open, this oil is pumped backwards and forwards by the pistons as the wheel (a) rotates round the crank (i). If the valves (e) are now slowly closed, motion will gradually be imparted to the crank (ii, until, on the complete closure of the valves, the shaft {k) will be driven at the same speed as the shaft (al). It will be seen that with this device any degree of slip may be obtained.

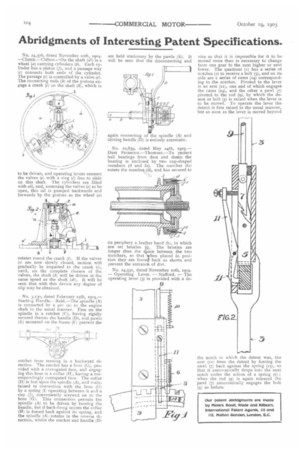

No. 3,930, dated February z5th, '9o5.— Starting Han d le .—Reid.—The spindle (A) is connected by a pin (a) to the engine shaft in the usual manner. Free on the spindle is a ratchet (CI, having rigidly secured thereto the handle (DI, and pawls (E) mounted on the frame (F) prevent the ratchet from turnilig in a backward direction. The ratchet has a boss (G), provided with a corrugated face, and engaging this boss is a collar (H), having a correspondingly corrugated face. The collar (II) is fast upon the spindle (A), and maintained in connection with the boss (G) by a spring (I) operating between it and a cup (j), conveniently screwed on to the boss (G). This connection permits the spindle (A) to be driven by turning the handle, but if back-firing occurs the collar (H) is forced back against its spring, and the spindle (A) rotates in the reverse direction, whilst the ratchet and handle (DI are held stationary by the pawls (E). It will be seen that the disconnecting and again connecting of the spindle (A) and driving handle (D) is entirely automatic.

No. 10,839, dated May 24th, 9905.— Dust Protector.—Thomsen.—To protect ball bearings from dust and damn the bearing is enclosed by two cup-shaped members (d and fz). The member (ft) enters the member (d), and has secured to its periphery a leather band (h), in which are set bristles (1)., The bristles are longer than the space between the two members, so that rhen placed in position they are forced' back as shown and prevent the entrance of dirt.

No. 24,331, dated November lath, 1904. — Operating Lever. — Stafford. — The operating lever (3) is provided with a de vice so that it is impossible for it to be moved more than is necessary to change from one gear to the next higher or next lower. The quadrant (1) has a series of notches (2) to receive a bolt (5), and on its side are a series of cams (4) corresponding to the notches. Pivoted to the lever is an arm (i i), one end of which engages the cams (r4), and the other a pawl (7) pivoted to the rod (9), by which the detent or bolt (5) is raised when the lever is to be moved. To operate the lever the detent is first raised in the usual manner, but as soon as the lever is moved beyond

the notch in which the detent was, the arm (1 i) frees the detent by forcing the pawl (7) back against the spring (i5), so that it automatically drops into the next notch under the action of a spring (h); when the rod (9) is again released the pawl (7) automatically engages the bolt (5) as before.