Upfront advantages

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

While the industry seems split over the benefits of longer trailers, CM looks at how relaxing EU artic length laws could help truck-makers deliver major fuel savings.

Words: Brian Weatherley I Images: Scania Although the consultants appointed by the UK's Department for Transport (Dfr) to study the benefits (or otherwise) of longer semi-trailers (LSTs) have yet to deliver their findings, the advocates and critics of longer artics have fired the first salvoes in what looks like turning into a protracted battle of words.

Those in the 'pro' camp are clearly attracted to the LST's increased carrying capacity. However, within the wider debate on longer artics, there's more at stake than just load space.

Relaxing the current 16.5m EU artic length by as much as 2.05m (as suggested in the Dfr's current study) could provide more room for drivers in their cabs at a time when the lack of decent overnight facilities is a major industry issue.

Equally significant, with more room to play with, truck designers could create a more aerodynamic profile than is currently found on today's cab-over tractors, which would allow them to pass more easily through the air, saving fuel and lowering emissions along the way. And within that `aero-nose', the manufacturers could build in more impact protection and extra cooling for the nextgeneration of Euro-6 engines.

Scania experiments

A number of truck-makers have already looked at the aerodynamic advantages to be gained with longer vehicle combinations and, at the recent Scania R-Series launch. Commercial Motor caught up with Per Elofsson, technical manager for aerodynamics within the manufacturer's chassis development group, to find out what the company has been doing with aero-noses.

Where once all major work on truck aerodynamics had to be verified in a windtunnel using scale models, or even full-size vehicles, now, automotive designers can test how 'slippery' their future products are through a process known as computational fluid dynamics (CFD). In simple terms, CFD allows chassis engineers to play 'what-if?' with various shapes in an electronic wind-tunnel using highly cost-effective computer modelling.

Moreover, by being able to programme in side-winds. or 'yaw', CFD provides an extremely accurate picture of what's likely to happen out on the road a significant advantage when few trucks spend their time driving constantly into a headwind!

Nose configurations

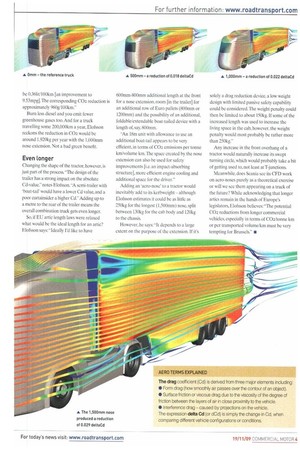

Using CFD. Elofsson and his team have been examining the performance of various extended nose configurations against a nominal 'reference truck' with a drag co-efficient (Cd) slightly lower (by around 0.050deltaCd see tint box right) than the latest R-Series Scania. In addition to simulating 'straight-ahead' runs, the extended nose models have also been CFD-tested in cross wind conditions with a yaw angle of 5 degrees.

The three different extensions 500mm, 1,000mm and 1,500mm have produced improvements (ie. a reduction) in the tractor's drag coefficient (deltaCd) of 0.018,0.022 and 0.029 respectively compared to the reference truck.

So far so good, but what do those improvements represent in terms of possible fuel savings?

"Based on all simulations, we estimate the wind averaged drag to be 0.024dCd for the vehicle with the 1,000mm nose extension," says Elofsson, adding: "For a 40-tonne tractor-semi trailer combination, this translates to a fuel consumption reduction of about 1.2%.The gain is even larger for a volume cargo combination with a lower weight. Assuming an initial fuel consumption of 30.01it/100km (9.4mpg), the fuel reduction will be 0.361it/100km [an improvement to 9.53mpg]. The corresponding CO2 reduction is approximately 960g/100km."

Burn less diesel and you emit fewer greenhouse gases too. And for a truck travelling some 200,000km a year, Elofsson reckons the reduction in CO2 would be around 1,920kg per year with the 1,000nun nose extension. Not a bad green benefit.

Even longer Changing the shape of the tractor, however, is just part of the process. 'The design of the trailer has a strong impact on the absolute Cd-value." notes Elofsson. -A semi-trailer with 'boat-tail' would have a lower Cd value, and a poor curtainsider a higher Cd." Adding up to a metre to the rear of the trailer means the overall combination truck gets even longer.

So, if EU artic length laws were relaxed what would be the ideal length for an artic? Elofsson says: "Ideally I'd like to have 600mm-800mm additional length at the front for a nose extension, room [in the trailer] for an additional row of Euro pallets (800mm or 1200mm) and the possibility of an additional, foldable/extendable boat-tailed device with a length of, say, 800mm.

An 18m unit with allowance to use an additional boat-tail appears to be very efficient, in terms of CO2 emissions per tonne km/volume km. The space created by the nose extension can also be used for safety improvements [i.e. an impact-absorbing structure], more efficient engine cooling and additional space for the driver.

Adding an 'aero-nose' to a tractor would inevitably add to its kerbweiuht — although Elofsson estimates it could be as little as 250kg for the longest (1,500mm) nose, split between 130kg for the cab body and 120kg to the chassis.

However, he says: "It depends to a large extent on the purpose of the extension. If it's solely a drag reduction device, a low weight design with limited passive safety capability could be considered The weight penalty could then be limited to about 150kg. If some of the increased length was used to increase the living space in the cab, however, the weight penalty would most probably be rather more than 250kg."

Any increase in the front overhang of a tractor would naturally increase its swept turning circle, which would probably take a bit of getting used to, not least at T-junctions.

Meanwhile. does Scania see its CFD work on aero-noses purely as a theoretical exercise or will we see them appearing on a truck of the future? While acknowledging that longer artics remain in the hands of Europe's legislators, Elofsson believes: "The potential CO2 reductions from longer commercial vehicles, especially in terms of CO2/tonne km or per transported volume/km must be very tempting for Brussels." •