ENVIRONMENTAL LEGISLATION DICTATES DESIGN

Page 37

Page 38

Page 39

Page 40

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

by Gibb Grace, DAuE, CEng, MIMechE Pictures by Dick Ross; sketches by John Way

SINCE the last Scottish Show, we have seen a change of Government. the establishment of the Department of the Environment and the decision to join the European Economic Community. These events and their implications have shaken vehicle manufacturers and operators alike and the net effect has been to force changes in established practices.

The furore of the 44-ton gtw truck gave way in due course to the effect of traffic generally on the environment; similarly the emphasis on "under-braked speeding killer trucks" moved on to concern with underpowered vehicles emitting smoke and causing delays.

Engineers are used to being restricted by economic forces but increasingly now they must consider environmental factors and many of the vehicles at this year's Scottish Show reflect this state of affairs.

Engine power and power to weight ratio Overladen or underpowered trucks, whichever way one looks at it, have always been a source of criticism and soon after obligatory plating of axles came legislation of minimum power to weight requirements. The figure of 6 bhp /ton has been adopted for the initial legislation but this may well be increased at some future date. Six bhp /ton, some people argue, is not high and will not affect many vehicles but the significant point is that the power output is defined as net installed hp and is to be measured as laid down in BS AU 141a: 1971. In the past it has been customary for manufacturers to give gross hp ratings — that is for a bare engine on a test bed with, in some cases, the fuel pump set to give the best results at all speeds. Two words — net installed — have changed all that and now the engine has to be rated in a more realistic way. Standard inlet and exhaust pressures, equivalent to typical manifolds, are used and the fuel pump regulation has to be characteristic of the engine. Such a test establishes the engine's net bhp but then further reductions have to be made from the net bhp dependent on the use within a particular vehicle. The two most common variables are the power absorbed by driving the cooling fan, and the power steering pump, should one be fitted.

Power which is only required while the vehicle is stationary, say the blower of a bulk discharge system, is not subtracted. The Rolls-Royce Eagle 265 engine, for example, has a BS AU 141a: 1971 net rating of 265 bhp. To drive a 22in. cooling fan at 1.33 times engine speed, however. uses 8 bhp and a power steering pump typically takes 2 bhp so the net installed hp becomes 255 bhp. Fan losses vary from installation to installation and a bigger fan at the same speed might take 12 bhp whereas a smaller fan at a lower speed might consume only 4 bhp.

The initial net rating, as I have said, must be measured according to BS AU 141a: 1971 which specifies a very low smoke emission level and in some instances the rated net hp may have to be reduced in order to meet the smoke level requirement.

Although, then, 6 bhp /ton laden may at first thought be on the low side one can see that it is a realistic starting point for the engine and vehicle manufacturers. Although the 6 bhp (net installed)/ton laden rule will apply to all new commercial vehicles registered after April 1 1973, in practice it will only affect trucks in the over 25 tons gvw category, say 8,000 vehicles per annum, for below this weight trucks generally have a better power to weight ratio than 6 bhp/ton.

With just under 18 months to go before the regulations come into force several engines have been certificated and vehicles which will comply produced. In fact, at the Show there are several vehicles which considerably better the regulations in this respect.

Both Atkinson and ERF have 32-ton gtw tractive units on show powered by the Gardner 8LX13 engine. This engine is rated at 240 bhp and although it is not certificated yet it is unlikely to fall below 230 net installed bhp and therefore give not less than 7 bhp /ton with a 32-ton gtw tractive unit.

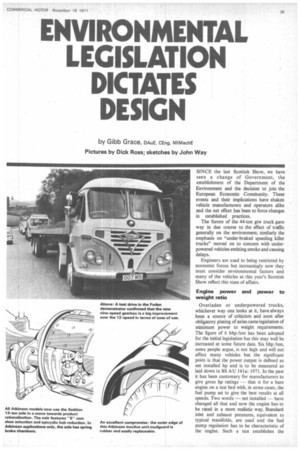

Rolls-Royce has two Eagle engines certificated already at 220 bhp and 280 bhp and both are at the Show installed in Scammell Crusaders. The 220 engine will produce not less than 206 bhp and the 280 not less than 265 bhp in net installed form, giving 6.4 and 8.2 bhp/ton on 32 tons gtw respectively.

Cummins in-line engines are in the process of being certificated at the moment and will all produce over the 192 net installed hp minimum necessary for 32-ton gtw. Cummins in-fine engines are installed in Atkinson, ERF, Foden, and Guy 32-ton gtw tractive units at this year's show.

The Perkins V8-605 engine, newly announced on the opening day of the Show, has been designed for a net BS AU 141a: 1971 rating of 205 bhp to enable it to achieve the 192 net installed bhp minimum required for a 32-ton gtw tractive unit. The first company to install the engine is Seddon and a 32-ton gtw tractive unit fitted with a new engine can be seen on the Central Motors stand.

External noise Hand in glove with the power and smoke regulations already mentioned are the latest noise requirements. Because of the difficulty of reasonably meeting the proposed requirements engines of above 200 bhp have been granted a stay of execution and no specific noise reducing packs are to be seen on the heavy vehicles at the Show. The ERF Gardner 8LXB engined tractive unit is fitted with an extended engine cowl but this provides weather protection rather than suppressing noise. An Atkinson Borderer at the Show also has a Gardner 8LX/3 engine and is shown without any form of rear cover. Atkinson has run vehicles with shielded engines and has found that it helps interior noise but not external noise. Experiments with fully shielded engines reduced exterior noise considerably but so far the lessons learnt have not come through to a production vehicle. The excessive cost is given as the reason but it is hoped to have at least an improved cab insulation option available early next year for about £25.

As engine size decreases the exterior noise level to which it must conform gets lower. The most extensive noise suppression treatment to be seen at the Show is on the DA 2818 Ford tractive unit. The insulation of the engine block and sump is Cummins developed while the shielding running up to cab level is Ford developed. This type of treatment must be expensive but nonetheless it will probably become commonplace as the regulations tighten up.

A further design restriction has been the uncertainty about the revised C and U Regulations. There has been much speculation since the dropping of the 44-ton gtw vehicle but at last we know the DoE proposals on this front (see page 16). In anticipation of the changes, British Leyland is showing two six-wheelers, an AEC Marshal and a Leyland Bison which have design weights of 24-ton gvw — 2 tons above the present limit for the wheelbase. ER F has on show an eight-wheeler at a design weight of 28 tons gvw, again 2 tons above the present limit for the wheelbase. These vehicles will no doubt be able to be used at the full design weight in the near future. Fodens have no rigids on show but the company's chief engineer assures me that whatever changes are announced Fodens will be in a position to supply vehicles to the new dimensions almost right away. Normally there is a time lag associated with a change in regulations but the range of Foden plated axle weights is such that almost any configuration of sixand eight-wheeled vehicle can be built without problem.

Among the heavy vehicles on show Fuller gearboxes are very common, almost all the 200 plus bhp engines are matched to one model or another of the Roadranger series and there is a noticeable lack of big torque capacity British gearboxes. The name of David Brown which is for many synonymous with gearboxes is regrettably absent despite the current design and development programme. Even British Leyland seems content to use the Roadranger box in Guy and Scammell models. Ford has gone ahead and invested in a new range of four-six-and eight-speed fully synchromesh gearboxes of its own design and manufacture. All the D-series trucks at the Show are fitted with the new boxes and a cutaway exhibition gearbox is on show.

Test drives

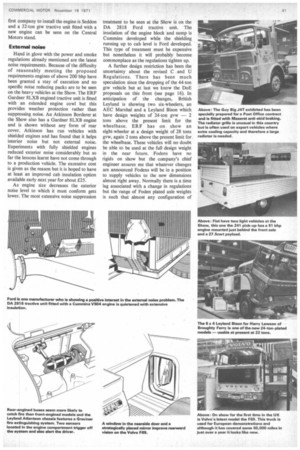

Fodens have made their own gearbox for a long time and just last week announced an improved nine-speed version of it. Fodens have a 32-ton gtw demonstrator artic at the Show and I had the opportunity of trying the new box on the road. The vehicle came fully laden at 32 tons and complete with demonstration driver, Tom Bowyer. I let Tom drive the vehicle out of the Glasgow traffic before I took over as a raggedly driven 50ft unit is not too popular, especially in congested areas, As it turned out I need not have worried; the new range-change box is very simple to use and I felt confident with it after just a few changes. The movements between gears are very light and satisfactorily positive in the Foden tradition. The range-change is also positive and quick, it changes easily within the time it takes to move the gear lever from the fourth to first position and vice versa. When changing from eighth to ninth — an overdrive ratio — one simply flicks the switch to high and depresses the clutch to make the change. There is no need to change into neutral and back into the same slot.

The big Cummins engine took a while to die down from 2100 to 1500 rpm as no clutch stop is fitted and this was the only factor needing attention. After a while I had 'adjusted' and the changes came very easily. In the course of the drive I was impressed by the very light, positive steering and suspected an experimental power steering set-up; however, when I queried this with Tom he assured me that the vehicle had no power steering fitted. I was driving, in fact, the standard manual set-up. With this level of performance as standard I cannot imagine why anyone should require power steering on this model. The S39 glass fibre cab is not as nice as the steel one and the seating position nowhere near as good as in the bigger cab. I would have liked the driver's seat two or more inches higher for comfort but as it was, my knee touched the wheel during clutch pedal use.

During the course of the Show I took two other short test drives. One was in the first Seddon Pennine VI chassis to be fitted. with a Duple 12-metre body. In the short time I had with the vehicle I was impressed by the driving position and the lightness of the Continued on page 47 controls. The relationship of pedals, seat and wheel were ideal and the view forward superb. The gear lever I found was nicely to hand but the gear positions needed a certain amount of concentration to find — with only some 250 miles from new this was hardly surprising. The clutch was particularly light in action and easy to use. Power steering was fitted and this I found light and responsive; unfortunately there was some shake in the column and wheel which was irritating.

For a rigid vehicle nearly 4011 long it handled very well, even parking presented no difficulties, rear vision with the aid of the mirrors fitted being very good. The Perkins T6.354 engine produces 155 bhp and gives the coach — 8.5 tons unladen — a lively performance. The engine is front mounted and for this reason sounds relatively noisy from the driving position. With the demonstration driver driving I tried most of the passenger seats and found that the noise level improves as one moves farther back.

Melvin Motors had a demonstration Commer KC25 3.5-ton gvw van converted to run on lpg fuel in the demonstration park and I took a short test drive in it.

The conversion is based on a petrol engine for cheapness and the petrol system is retained for convenience. Either system, petrol or gas, can be selected by fficking a switch on the dash. The vehicle started easily on both petrol and gas, and changed over from one system to the other without trouble while still running. My short drive was on gas and I could detect no peculiar differences; the vehicle sounded the same and had a comparable performance to the petrol version. The conversion costs £170 whereas a diesel option on the same van costs £175 but additionally saves about 3ewt over the diesel on the payload allowance. Other advantages that are fairly well substantiated now are reduced fuel costs — 17p reducing to as low as 9p per gallon as opposed to 34p a gallon for diesel (though this comparison will alter if the Government's proposed lpg tax is introduced) and improved maintenance periods. The combustion is so complete that if the engine is run on gas only, the lubricating oil lasts for 15,000 to 20,000 miles between changes. The exhaust was absolutely clean and is non-toxic, making the vehicle suitable for operating in confined spaces. The equipment is supplied by Lipton and a conversion takes two to three days.

British products improving — but not fast enough Many small changes for the better in terms of driver comfort and vehicle reliability are evident in the British models on show but in some obvious respects their Continental counterparts are still superior. Perhaps British membership of the EEC, and the subsequent likely increase in British truck prices, will provide the impetus for a new generation of trucks able to compete successfully with the best on the Continent in styling, driver comfort and long, trouble-free life.

At all levels from 2-ton-gvw delivery vans to 32-ton-gtw tractive units, cab design, control layout, instrumentation and fittings on the European vehicles convey an integrated design approach and a neat attention to detail. They are not cheap, but Continental operators — and a significant number of British ones' — seem undeterred by price.

When one realizes that many of the foreign heavies are quite old designs it seems obvious that if our manufacturers are• to ward off future Continental competition in our home market their products will need more operator and driver appeal; and if they are to be successful in Europe against future foreign products they will need to make a "quantum jump".

In the medium and light ranges, UK makers are in a much stronger position, and it is the Continentals who need to worry; already our smaller vehicles have gained a value-for-money reputation on the European mainland.