The Purchase Department.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Where to Buy your Supplies. 17 You Can Get It At "M.S." (Birmingham).—The brake lining for which you inquire is made by the Autobestos Syndicate, 3, Leicester Street, London, W.

" S.T." (Woolwich).—You can obtain timber for the purposes you require from Thomas Williams and Sons, Bent Timber and Wheel Works, Bristol.

'Owners" (Birmingham).—For the cast-aluminium brackets you require you should get in touch with R. W. Coan, 219, Goswell Road, London, E.C. " J.G.J." (West Dulwich).—Damaged radiator of your lorry will be effectively repaired by Randall's Radiator Hospital, Green Street Works, Paddington Green, W.

Well-made Piston Rings.

Engineers and chassis builders in general will at once realize the advantage of specifying piston rings turned out by firms specializing in their manufacture. For use in modern internal-combusfion engines in particular, piston rings should be made of a hard, close-grained cast-iron possessing a high percentage of carbon. To give the piston ring the desired amount of spring, and yet retain a certain degree of stiffness, the amount of carbon should he correctly determined and must be in as combined a form as possible. An old-established concern which has long been specializing in piston-ring manufacture is the British Chuck and Piston Ring Co., Ltd., Coventry, and the consistent good quality of its productions is well known to both user and manufacturer alike.

The rings turned out by this concern are remarkable for their uniformity of hardness and temper. One of the outstanding points in their manufacture is that each ring is hardened after being turned and parted off. The company is well-equipped for producing piston rings in large quantities, and will be pleased to submit designs and samples to persons interested. •

Substitute Tor Aluminium. '8 It is readily admitted that pure aluminium is unsuited for a majority of mechanical-engineering purposes where lightness of construction combined with stability is desirable. It possesses little mechanical strength, whilst it calls for additional care in casting, and does not lend itself to easy machining. Metallurgists and others have been trying for some time past to discover an alloy substitute in which none of the previously-mentioned disadvantages exists. We have had brought to our notice an alloy marketed by the Ormiston Metal Co., Ltd., 6, Holborn Viaduct. London, E.C.. which is claimed to possess many advantages which render it an excellent substitute for aluminiuin. Amongst other features the maker claims that Ormiston metal will satisfactorily withstand atmospheric conditions, whilst it can be treated to a remarkable degree of hardness, moreover it has a tensile strength equal to that of ordinary mild-steel. The Ormiston metal is bright and white in colour, as it comprises a large proportion of aluminium.

The alloy can be soldered, welded, or brazed with an ordinary blow-lamp or soldering-iron, and it can B14 be readily joined to any other metal. The joint so treated will not change its colour, and becomes homogeneous with the metal itself. Ormiston will readily fuse, and does not quickly disintegrate, whilst an additional point in its favour is that it is inexpensive. The marketing of a light alloy such as Ormiston should fulfil a long-felt want.

The Swindell Revolving-head Vice.

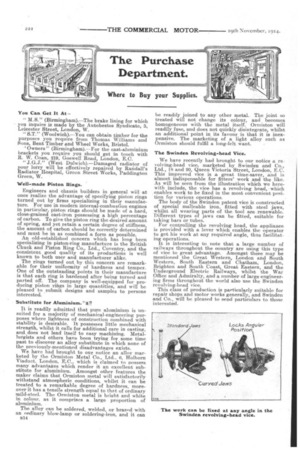

We have recently had brought to our notice a re• volving-head vice, marketed by Swinden and Co., Ltd., 18 and 20, Queen Victoria Street, London, E.C. This improved vice is a great time-.saver, and is almost indispensable for fitters' work and the like. As will be seen from the illustration which we herewith include, the vice has a revolving head, • which enables work to be fixed in the most convenient position for various operations.

The body of the Swinden patent vice is constructed of special malleable iron, fitted with steel jaws, whilst all wearing parts of the tool are renewable. Different types of jaws can be fitted, suitable for taking bars or tubes. For controlling the revolving head, the appliance is provided with a lever which enables the operator to get his work at any required angle, thus facilitating operations.

It is interesting to note that a large number of railways throughout the country are using this type of vice to great advantage. Amongst these may be mentioned the Great Western, London and South Western, South Eastern and Chatham, London, Brighton and South Coast, Great Eastern, and the Underground Electric Railways, whilst the War Office and Admiralty, and a number of large engineering firms throughout the world also use the Swinden revolving-head vice.

This class of production is particularly suitable for repair shops and motor works generally, and Swinden and Co, will be pleased to send particulars to those interested.