road and workshop

Page 76

If you've noticed an error in this article please click here to report it so we can fix it.

by Handyman

Auto-electrics for the mechanic (20)

IN an earlier article I explained that transistors have now begun to play a part in the ignition side as well as in voltage regulation in that a transistor can now take over the duty of the contact breaker. However, the majority of coil ignition systems still use the mechanically operated make and break method, and I will explore this a little further: first, the complete route taken by the low-tension current, ie the ignition circuit. Current is taken at battery voltage via a fuse to ignition switch and ammeter where fitted, to the SW terminal on the coil, then continues through the primary winding past the connection to the secondary coil and on internally to the CB terminal. From there it goes by outside cable to the contact breaker terminal and across the closed contact points to earth, completing the low-tension circuit.

Still on the low tension circuit, it will be found that other units have been coupled into this circuit between the ignition switch and coil — for instance, flasher units, reversing lamps, fog lamps, dashboard cigar lighters, etc, where they cannot be used unless the engine switch is on, which is a desirable feature. The electric petrol pump will also be found coupled into this circuit.

Contact breaker To return to the contact breaker, as stated, for a four-cylinder engine there will be a four-lobe cam, which on a four-stroke engine will revolve at half-engine speed. Thus for one revolution of the cam, the points will have opened and closed four times, and as the points open and break the low-tension circuit, the secondary coil produces a high voltage, which drives current through the HT lead from the coil to the distributor cap connection, down to the rotor arm via a small carbon brush. If the timing is correct the rotor arm will be in position facing the appropriate electrode in the distributor .cap to pass the current straight to the plug. Remember that the current has to jump two air gaps; (A) at the rotor arm under normal atmospheric pressure; and (B) at the plug gap itself.

Here it is important that the plug is clean and the plug points are at the stated gap — this can vary with different engines but is usually 0.025in. although on highperformance engines it can be up to 0.028in. Allowing plug points to serve too long and burn wide causes the coil to attempt a higher voltage, and the likely result is that the plug will either begin to spark up inside its body with a noticeable loss of power, or on a particular day the plugs will fail to ignite the mixture. Therefore with both the contact breaker and plug points the service attention period indicated by the maker should be adhered to.

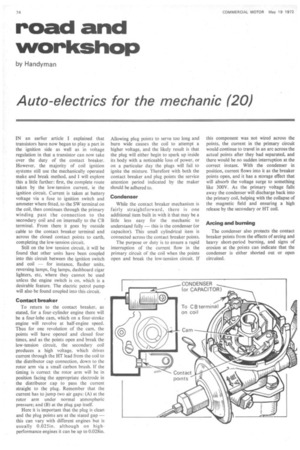

Condenser While the contact breaker mechanism is fairly straightforward, there is one additional item built in with it that may be a little less easy for the mechanic to understand fully — this is the condenser (or capacitor). This small cylindrical item is connected across the contact breaker points.

The purpose or duty is to ensure a rapid interruption of the current flow in the primary circuit of the coil when the points open and break the low-tension circuit. If this component was not wired across the points, the current in the primary circuit would continue to travel in an arc across the actual points after they had separated, and there would be no sudden interruption at the correct instant. With the condenser in position, current flows into it as the breaker points open, and it has a storage effect that wifl absorb the voltage surge to something like 300V. As the primary voltage falls away the condenser will discharge back into the primary coil, helping with the collapse of the magnetic field and ensuring a high release by the secondary or HT coil.

Arcing and burning The condenser also protects the contact breaker points from the effects of arcing and heavy short-period burning, and signs of erosion at the points can indicate that the condenser is either shorted out or open circuited.