Patents Completed.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

A " Super-resilient " Tire. A Progressively.,sprung Shock Absorber.

T. KaraaNJEE and A. B. PARANJAPE, No. 18,433, dated 13th August, 1913.—This specification describes an arrangement of valves for internal-combustion engines 'whereby an extra supply of compressed air is admitted to the cylinder after a normal charge has been drawn in a larger charge of fuel can be burnt by virtue of this extra air and thus more power can be developed.

The invention is illustrated as applied to a these. engine. When the piston is on ifs suction stroke, air is drawn in through-the non-return flap-valve at the side, as well as the ordinary mechanically-operated air-inlet valve in the head. When the piston starts on its compression stroke, the flapvalve closes, but the cylinder air-valve is kept open, and an auxiliary air-valve is opened „mechanically to admit compressed air from a reservoir. This admission continues until the compression stroke is nearly half-finished. All the valves are then closed and the true compression commences.

The compressed-air inlet valves are opened again at the end of the exhaust. stroke, so that the exhaust gases are effectively removed from the clearance space of the-cylinder, and the new charge of air is free from impurity.

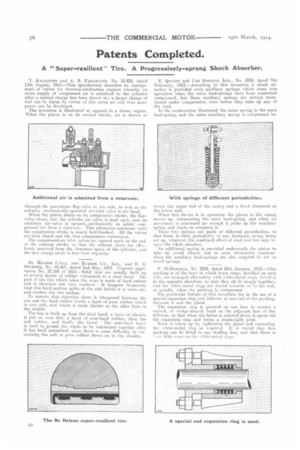

ST. HELENS CABLE AND RUBBER CO., LTD., and E. S. SEviitouR, No. 10,407, dated 2nd May, 1913. Cognate application No. 21,184 of 1913.—Solid tires are usually built up of several layers of rubber vulcanized to a steel band. The part of the tire which takes the wear is made of hard rubber and is therefore not very resilient. It happens frequently that this hard portion splits at the side before it is worn out, and renders the tire useless.

To remove this objection there is interposed between the rim and the hard rubber tread, a layer of pure rubber which is very soft, and which is made thicker at the sides than in the The tire is built up from the steel band, a layer of ebonite is put on over this, a layer of semi-hard rubber, then the soft rubber, and finally the tread. The semi-hard layer is used to permit the whole to be vulcanized together after it has been assembled, since there is some difficulty in vulcanizing the soft or pure rubber direct on to the ebonite.

E. QUAINT and CAR SPRINGS, LTD., Nu. 3259, dated 7th February, 1913—According to this invention a shock absorber is provided with auxiliary springs which come into operation when the main load-springs have been somewhat compressed, but these auxiliary springs are always maintained under compression, even before they take up any of the load.

In the construction illustrated the inner spring is the main load-spring, and the outer auxiliary spring is cnropressed he tween the upper end of the casing and a fixed abutment at the lower end.

When this device is in operation the piston in the casing moves up, compressing the main load-spring, and when its movement is continued far enough it, picks up the auxiliary spring and starts to compress it. These two springs are made of different periedicities, so that there is little probability of any harmonic se lug being Set up, whatever the combined effect of road and tire may be upon the whole absorber. An additional spring is provided underneath the piston to take up recoil effects, but in some alternative constructions the auxiliary lead-springs are also adapted to act as recoil springs.

P. McDoNNELL, No. 2259, dated 28th January, 1913.—This packiug, is of the type inn which brass rings, bevelled on each side, are arranged alternately with white-metal rings, bevelled in the opposite direction, so that they all lit snugly together, and the white-metal rings are forced inwards on to the rod,. or spindle, when the packing is compressed.

The particular feature of this invention lies in the use of a special expansion ring and follower at one end of the packing, between it and the gland. The expansion ring is grooved on one face to receive a curved, or wedge-shaped, bead on the adjacent face of the follower, so that when the latter is screwed down it opens out the expansion sing and forms a steam-tight joint. Wear is taken up by tightening the gland and expanding the white-metal ring as required. It is stated that thispacking can be fitted to any stuffing box, and that there is

• ry little wear on the white-metal