ROADSIDE AND GARAGE.

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions from Our Driver and Mechanic Readers.

Cleaning by a Jet of Hot Water.

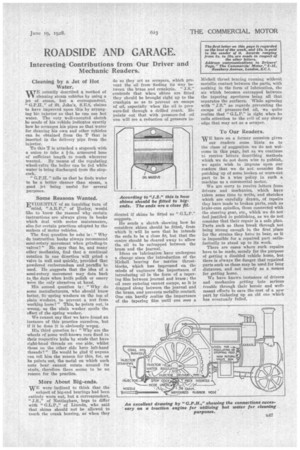

WE recently described a method of cleaning steam vehicles by using a jet of steam, but a correspondent, "G.P.H.," of St. John's, S.E.8, claims to have improved upon this by arranging his injector so that he CCM use hot water. The very well-executed sketch he sends of his vehicle indicates exactly how he arranges his pipes so that water for cleaning his own and other vehicles can be obtained from the T that is inserted in the delivery pipe from the injector.

To this T is attached a stopcock with a union to take a armoured hose of sufficient length to reach wherever wanted. By means of the regulating wheel-valve the boiler can be fed while water is being discharged from the stopcock.

" G.P.H. " tells us that he finds water to be a better cleaner than steam, a good jet being useful for several purposes.

Some Reasons Wanted.

EVIDENTLY of an inquiring turu of

mind, " A.R.P.," of Vorley, would like to know the reasons why certain instructions are always given in books which deal with motor maintenance, also for certain practices adopted by the makers of motor vehicles.

The first question he asks is: "Why do instruction books always recommend semi-rotary movement when grinding-in valves?" He says that he, and many other mechanics, End that a continual rotation in one direction will grind a valve in well and quickly, provided that powdered carborundum and paraffin be used. He suggests that the idea of a semi-rotary movement may date back to the days when knife polish or emery were the only abrasives at hand.

His second question is: "Why do some manufacturers, who should know better, fit spring washers on the top of Plain washers, to prevent a nut from working loose?" This, he points out, is wrong, as the plain washer spoils the effect of the spring washer.

We cannot say that we have found an instance of this practice ourselves, but if it be done it is obviously wrong. His third question is : "Why are the wheels of some well-known cars fixed to their respective hubs by studs that have right-hand threads on one side, whilst those on the other side have left-hand threads?" He would be glad if anyone can tell him the reason for this, for, as he points out, the metal on which such nuts bear cannot rotate around its studs, therefore there seems to be no reason for the practice.

More About Big-ends.

WE were inclined to think that the subject of big-end bearings had been entirely worn out, but a correspondent, " J.S.," of Nottingham, begs to differ with " G.L.P.," of Lincoln, who said that shims should not be allowed to touch the crank bearing, as when they do so they act as scrapers, which prevent the oil from finding its way between the brass and crankpin. " J.S." contends that when shims are fitted they should be brought right up to the crankpin so as to prevent an escape of oil, especially when the oil is pressure-fed through a drilled crank. Ile points out that with pressure-fed oil one will see a. reduction of pressure in dicated if shims be fitted as suggests. He sends a sketch showing how he considers shims should be fitted, from which it will be seen that he intends the ends to be a close fit, but that the centre should be cleared away to allow the oil to be entrapped between the brass and the journal.

Ideas on lubrication have undergone change since the introduction of the Michell bearing for marine thrustblocks, which has impressed on the minds of engineers the importance of introducing oil in the form of a tapering film between journal and brass: the oil once entering cannot escape, so it is dragged along between the journal and the brass, and prevents metallic contact. One can hardly realize the importance of the tapering film until one sees a

Michell thrust bearing running without metallic contact between the parts, with nothing in the form of lubrication, the air which becomes entrapped between the tapering apertures being all that separates the surfaces. While agreeing with " J.S." as regards preventing the escape of pressure-fed oil, we quite realize that " G.L.P." is right when he calls attention to the evil of any sharp edge that may act as a scraper.

To Our Readers.

WE have on a former occasion given

our readers some hints as to the class of suggestion we do not welcome in this page, but as we continuo to receive letters describing methods which we do not deem wise to publish, we again wish to impress upon our readers that we do not consider the patching up of some broken or worn-out part to be a wise policy in such a machine as a commercial motor.

We are sorry to receive letters from drivers and mechanics, which have taken some time to write, and sketches which are carefully drawn, of repairs they have made to broken parts, such as brake-cam spindles, those connected with the steering gear, etc., which we do not feel justified in publishing, as we do not consider that their repair is a safe plan. Parts such as these break through not being strong enough in the first place for the strains they have -to bear, so it is impossible for a repaired part satisfactorily to stand up to its work.

There are eases where such repairs have to be made, merely for the purpose of getting a disabled vehicle home, but there is always the danger that repaired parts such as these may be used for long distances, and not merely as a means for getting home.

We have known instances of drivers and mechanics getting into serious trouble through their heroic and wellmeant efforts to save the cost of a new part by tinkering up an old one which has eventually failed.