Novel Multi-purpose Tipping Body

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

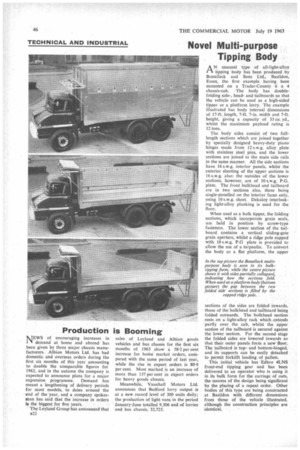

AN unusual type of all-light-alloy tipping body has been produced by Bonallack and Sons Ltd., Basildon, Essex, the first example having been mounted on a Trader-County 6 x 4 chassis-cab. The body has doublefolding side-, headand tailboards so that the vehicle can be used as a high-sided tipper or a platform lorry. The example illustrated has body internal dimensions of I7-ft. length, 7-ft. 7-in, width and 7-ft, height, giving a capacity of 33 cu. yd., whilst the maximum payload rating is 12 tons.

The body sides consist of two fulllength sections which are joined together by specially designed heavy-duty piano hinges made from 12 s.w.g. alloy plate with stainless steel pins, and the lower sections are joined to the main side rails in the same manner. All the side sections have 16 s.w.g. interior panels, whilst the exterior sheeting of the upper sections is 16 s.w.g. also: the outsides of the lower sections, however, are of 10 s.w.g. P.G. plate. The front bulkhead and tailboard are in two sections also, these being single-panelled on the interior faces only, using 10 s.w.g. sheet. Dekaloy interlocking light-alloy planking is used for the floor.

When used as a bulk tipper, the folding sections, which incorporate grain seals, are held in position by screw-type fasteners. The lower section of the tailboard contains a vertical sliding-gate grain aperture, whilst a ridge pole capped with 10 s.w.g. P.G plate is provided to allow the use of a tarpaulin. To convert the body to a flat platform, the upper sections of the sides are folded inwards, those of the bulkhead and tailboard being folded outwards. The bulkhead section rests on a light-alloy rack which extends partly over the cab, whilst the upper section of the tailboard is secured against the lower section. For the second stage the folded sides are lowered inwards so that their outer panels form a new floor. The tailboard is topand bottom-hinged, and its supports can be easily detached to permit forklift loading of pallets.

This initial vehicle has 'Edbro 4LNS front-end tipping gear and has been delivered to an operator who is using it in its bulk form for the carriage of oats, the success of the design being significant by the placing of a repeat order. Other bodies of this type are being constructed at Basildon with different dimensions from those of the vehicle illustrated, although the construction principles are identical.