ROADSIDE AND GARAGE.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

A Page for Drivers, Mechanics and Foremen.

A Hydraulic Wheel Puller.

The sender of the following communication has been awarded the extra payment of 5s. this week.

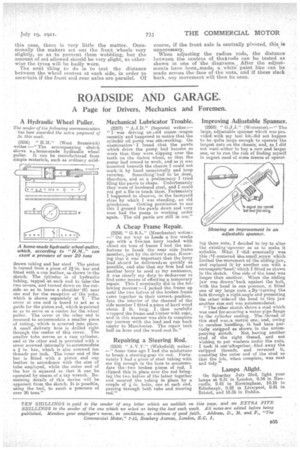

(2256) " ELM," (West 13romwich) writes :—" The accompanying sketch shows ashome-made hydraulic: wheel puller. It can be manufactured from simple materials, such.as ordinaey solid

drawn tubing and bar steel The piston is earned from a pieoe of 2in. bar and fitted with a cup leather, as shown in the sketch. The cylinder is of hydraulic tubing, tapped•at each end to take•the two covers, and turned down on the outside so as to leave a shoulder' (8) near one end for the reception of the yoke, which is shown separately at Y. The cover at one end is bored to act as a guide for the piston rod, which is pointed so as to serve as a centre for the wheel puller. The cover at the other end is. recessed to accommodate a smaller piece of tubing,which is screwed into place. A small delivery hole is drilled right through the centre of this cover. The smaller tube serves as a ram cylinder, and at its other end is provided with a cover screwed internally to accommodate a in. bar, which is also screwed ten threads per inch. The inner end of the bar is fitted with a piston and cup leather in accordance with the size of tube employed, while the outer end of the bar is squared so that it can be operated by means of a tap wrench. Remaining details of this device will be apparent from the sketch. It is possible, using the tool, to exert a pressure of over 20 tons."

Mechanical Lubricator Trouble.

(2257) " A.J.D." (Sapcote) writes :— " I wee driving an sold steam' •wagon recently and happened to notice that the cylinder oil pump was ntteworking. .0n examinationI found ;that the pawls which drive the pump had become so worn that they were slipping over the teeth on the rachet wheel, so that the :pump had ceased to work, and as it was mounted beneath the chassis I could not work.' it by hand occasionally and keep

running. Something l had to 'be done, therefore, and as a preliminary I tried filing the pawls to shape. Unfortunately they were or hardened steel, and I could not get a file to touch them. Fortunately' I happened to observe, in the farmyard close by which I was standing, an old grindstone. Getting permission to use this I ground the pawls down and very soon had the pump in working order again. The old pawls are still in use."

A Cheap Frame Repair.

(2258) " G.B.L." (Manchester) writes: —" On my 'ray to Leeds a few weeks ago with a five-ton lorry loaded with about six tons of bacon I had the misfortune to break the near side frame member, just by the driver's seat. Knowing that it was important that the lorry load should be deliveredi as quickly as possible, and also that my firm had not another lorry to send to my assistance, it was clearly my duty to endeavour to find some means of effecting a temporary repair. This I eventually did in the fol lowing manner jacked •the. frame, up until the two halves of the broken frame came together in their correct-posit-ion. Into the interior of the channel of the' side member I fitted apiece of hard wood about 2 ft. long. I. then carefully -wrapped the frame and timber with.rope, and in this manner was able to complete my journey with the load.and run back empty to Ifanchester. The repair took half an hour and the wood cost 2s."

Repairing a Steering Rod.

(2259) " A.V.T." (Wakefield) writes t Some time ago I had the misfortune to break a steering-gear tie rod. Fortunately I had a piece of steel tubing with me big enough in the bore to accommo. date the-' two broken pieces of rod. I slipped this in place over the rod bringing the two halves of the latter together and secured the tubing in place by a couple of * in, bolts, one at each end, passing through both tube and steering rod."

Improving Adjustable Spanner.

(2260) " G.J.J.", (Worcester).—" The large, adjustable spanner which was provided with my tool kit,did not happen to be quite large, enough to operate the largest nuts on the chassis, and, as I did not want either to buy a now and larger one, or to run the risk of finding myself in urgent need of some means of operat.

ing those nuts, I decided to try to alter the existing 'spanner so as to make, it suitable. .What I 'dideventually was Ws :II 'removed the, small.screw which limited the movement of the sliding jaw, and replaced it' by another one with a reetangatar.hearl; which I fitted as shown in the sketch_ One side of the head -was longer than another. When the sliding jaw was drawn' back against the bolt, with the head in one position, it fitted one of my large nutsa By 'turning the be-lt through a right-angle and presenting the other sideeof the head to this jaw another size nut was accommodated.

"The other sketch 'shows a stud which was used for-securing a water-pipe flange to the cylinder casting. The-thread of this stud was,a metric one, and, owing

to careless handling, it been partielly stripped as shown in the accom

panying _sketch. Not, having another stud of the right thread, and not wishing to put washers under the nuts, I took it outsaltogethere filed away the etripped threads, and reversed it, rounding the outer end of the stud so that the job, when complete, was neat and tidy

Lamps Alight.

On Si.tnrday July 23rd, light your lamps at 9.31 in London, 9.54 in Newcastle, 9.42 in Birmingham, 10.16 in Edinburgh, 9.52 in Liverpool, 9.41 in Bristol, and 10.35 in Dublin.