THE BATHER SPLASHGUARD.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

THE NUMBER of splashguards which has been devised during recent years is high, but the number of even partially successful devices is remarkably low, as was shown by the recent splashguard trials held under the auspices of the Camberwell Borough Council.

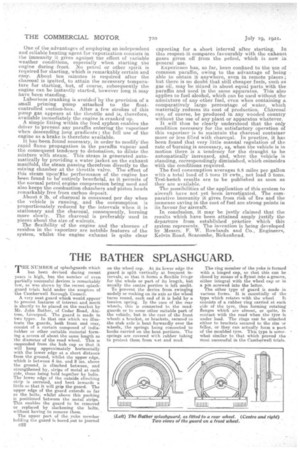

A. very neat guard which would appear' to present features of interest and merit is shortly to be placed on the market by Mr. John Bather, of Cedar Road, Aintree, Liverpool. The guard is made in two types. In that one which we illustrate the guards, both front. and rear, consist of a curtain composed of indiairubber or other suitable material forming a screen of about the same length as the diameter of the road wheel. This is suspended from the hub cap so that it will hang approximately horizontally with Bic lower edge at a short distance from the ground, whilst the upper edge, which is between 4 ins. and 8 ins, above the ground, is clinched between, and strengthened by, strips of metal at each side, these being held together by bolts. The lower edge of the outside clinching strip is serrated, and bent inwards a little so that it will grip the guard. The upper edge of the guard extends as far as the bolts, whilst above this packing is positioned between the metal strips. This enables the guard to be removed or replaced by slackening the bolts, without having to remove them.

The upper part of the yoke member holding the guard is bored ,out to journal 022 on the wheel cap. At its lower edge the guard is split vertically at frequent intervals; so that it forms a flexible fringe for the whole or part of its length, but usually the centre portion is left unsiit.

To prevent the device from swinging unduly or rocking on its axis as the wheel turns round, each end of it is held by a tension spring. In the 'case of the rear wheels, this is connected to the mudguards or to some other suitable part of the vehicle, but in the case of the front wheels a bracket, or brackets, secured to the stub axle is bent forwardly over the vheels, the springs being connected to hooks carried on the bent portions. The springs are covered with rubber tubing to protect them from net and mud.

The ring member of the yoke is formed with a hinged cap, so that this can be closed by moans of a flynut into a groove, either integral with the wheel cap or in a pin screwed into the latter.

The other type of guard is made in various forms. It is essentially of the type which rotates with the wheel It, consists of a rubber ring carried at each side of the tyre, thus forming rotating flanges which are almost, 9r quite, in contact with the road when the tyre is under load. The rings can be attached either to brackets secured to the rim or felloe, or they can actually form a part of the moulded tyre. This type is somewhat similar to that which proved the most successful in the Camberwell trials.