SIZE DOES MATTER!

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

'More productivity' is among the Chancellor's clarion calls — so perhaps someone should tell the Transport Secretary about longer wagons. John Dixon-Simpson reports.

productivity gains of up to 60% can be achieved without compromising current standards of manoeuvrability and safety with Longer Heavier Vehicles (LHVs).T1ris has been proved over the past two years in trials by the British Transport Advisory Consortium (BTAC) at the testing grounds of the Motor Industry Research Association (M IRA), not least with Denby Transport's innovative Eco-Link B-Double.

The BTAC conclusion is clear: if vehicle lengths were more closely aligned with the load units that have to be carried, the productivity improvement could be immense —trials indicate a potential of up to S4% .That must surely be aTreasury tempter.

Nonetheless, this issue has, temporarily at least, been kicked into the long grass nurtured by consultants (CM 15 December 2005).

When looking for a logical conclusion, you might assume the starting point is what trucks are expected to can-y. which translates into the standardised unit loads used in global trade.

There are two major groups of unit loads: pallets and containers. Neither can be carried with maximum efficiency within the current length limits.The packaging and assembly of goods into standard-size units ensures that many trucks run out of space so they frequently run short of their weight capability.

To take neat multiples of pallets, whether 800x1,20(hnm or I ,000x1,200mm, the length increment for bodies should he four metres plus a bit of shuffle room as well as the thickness of bulkhead and doors.That implies overall lengths of 4,2.8.25 or 16.4m to take account of insulated bodywork.

Lack of versatility

It is from these figures that the argument for longer vehicles ought to stem. A nominal 8m body has floor space for exactly 20 europallets or 16 imperial pallets. In comparison, the international standard swap bodies (based on dimensions devised for German railways) are nowhere nearly as versatile.

None of the 7.15,7.45 or 7.82m standard lengths can take more than 14 imperial pallets; even with europallets, each increment in swap-body length of accommodates just one more pallet.

Despite this, these swap-body standards are the basis of the 18.75m drawbar length limit. If the length were 19.511m, two 8.2m bodies could be transported. boosting imperial pallet capacity by 12.5%.Tbrec of these bodies could be carried by a 27.7m drawbar outfit or a 28m double semi-trailer B-train.

In other words. the cargo-carrying capacity should not be determined by the vehicle length. Quite the opposite. Enough waste has been caused by putting 13.6m semi-trailers at the heart of length limits.Yes, it is an exact multiple of europallets, but with imperial pallets 600mm goes to waste.

In any case, the crucial need was to have 13.6m inside length,not outside length. So extra expense has been incurred in chamfering front corners so that 13.7m can be obtained externally to get 13.6m internally.

A revision of lengths could make efficient operation considerably easier to achieve.The economies of intermodal co-ordination with rail freight would obviously be enhanced if artics were long enough to carry two standard swap bodies.

And if the sensible swap-body length of 8.2m were to be accepted by the legislators, a I 9.3m artic would be able to deal with any swap body or container,including an American 52-footer.

Outdated attitude But the narrowness of vision persists. Even in the current proposals for longer truck-trailer outtits,we are obsessed with 13.6m semi-trailers and 7.82m swap bodies.The Continental philosophy seems to be 'the [maximum] length of combination shall be 25.25m' inappropriate in an era of global trade. Europe is imposing economic penalties on itself with these arbitrary constraints on its freight transport. Too much frustration is already caused by having to devise ingeniously versatile skeletal semi-trailers to handle the variations in the containers that world shipping deposits on European docksides. Again,the problem is incongruous length limits-and sometimes height limits too.

Lengths formed around 13.6m bodies do not legally suit 13.725m (45ft) containers.The legislators even refuse to increase the artic length limit by a paltry 100mm to I 6.6m.The solution they offer is to transport 45-footers only if their front corners are chamfered, an attitude worthy of King Canute as maligned by myth.

There are more 45ft containers with square corners than with chamfers, so the more enlightened European states ignore their technically illegal transport.

Meanwhile, trailers have lobe equipped take either type of 45ft containerquite ar From other variations such as fore-section ( tunne1,9ft 6in height and refrigeration plat Unnecessarily elaborate trailers are havinj be bought with extra container locks, telesc ic chassis, extendible front and rear ends ar sometimes, a variable bogie position as wel axle loadings can be adjusted.

A great deal of ingenuity also has to be channelled into saving weight because the legal gross ratings are no longer generous f the duties imposedand this is in a period when tractor weights have gone up, partly result of legislation.

Intermodal servicing The reasoning that led to the 44-tonne combination limit began with the recogniti that 401t containers could weigh 30 tonnes. artic able to carry that load weighed about tonnes: hence the 44 total.

Since then. vehicles have becomi heavier and the railways have introduced 13.6m swap bodies ra at 34 tonnes gross.

To assure legal intermodal servicing of rail freight, the combination weight limit sho be raised to 48 tonnes-and there's no sign of this on the legislative agenda.

Beyond the talk of permitting 25.25m comb Lions in the EU as well a Scandinavia, Stafford haulier Stan Rohinsoi wants to try an A-trai an artic towing a Ira allowing two 13.6 semi-trailers to be

moved in one trir

Obviously, doubl the load capacity the number of trucks needed to move a giver amount of freight. Fuel move a tonne of load 100km is slashed to about a litre, which is nearly a third less than a 44-tonner achieves.

Robinson camp acknowledges nervousness about 31 m trucks. but stresses their economic and environmental values even if restricted to special-licence duties.

Designated routes One example of their potential would be shunting containers between the proposed London Gateway deep-sea port and a holding depot close to the M25. Concerns have been raised in Essex about the lorry traffic that the new port might create. But the num her of movements would be heavily reduced if containers could be carried two at a time.

If there is to be a role for Robinson-style roadtrains it would probably be in the context of designated routes, while the other longer combinations being trialled need not be subject to such restrictions.The A-train cannot, without steering axles, meet the legal turningcircle requirements; a longeCtuck-under' drawbar is advisable to satisfy concerns about dynamic stability:and drive-tyre slip would need the cure of a double-drive tractor.

The double-artic B-train is not subject to these problems. Analyses of handling dynamics in Australia,Canada and New Zealand have rated the B-train as more docile than a drawbar rig with better braking distribution than a conventional artic.

Trial findings

'llic B'IAC trials at MIRA have confirmed these findings. Slalom swerves on an icy-grip track did not cause off-tracking or even a hint of jack-knifing.The dynamic braking was distributed better than an artic's, with dry-road efficiency of 73%.

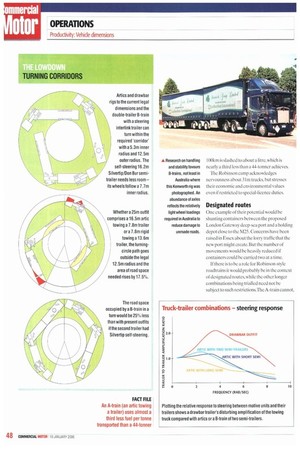

Operators at the BTAC trials took a rational approach to dealing with concerns about longer trucks: legislate on the basis of manoeuvrability.The trials included turningcircle tests to compare the longer vehicles' manoeuvrability with the requirement to stay within a circular corridor formed by radii of 12.5 and 5.3m.

This can just be met by current top-size artics Denby Transport's double artic B-train with its steered interlink semi-trailer made it round the legal circle with a foot to spare.The Morrisons artic with self-steering Don-Bur 16m trailer did it with 2.4m to spare; a Scania tractor with steering tag axle took the B-train around the circle 750trun tighter than when it was hauled by a tractor with a steering mid axle.

This raises a logical question: if a combination can weave through traffic and go around corners at least as well as current artics, why bother too much about its length!.