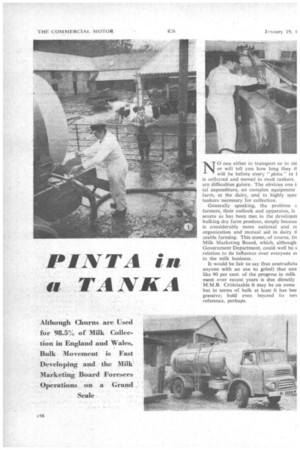

PINTA in TANKA

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

NO one either in transport or in mi or will tell you how long they a will be before every " pinta " in 1 is collected and moved in road tankers, are difficulties galore. The obvious one i: Lai expenditure, on complex equipment farm, • at the dairy, and in highly spec tankers necessary for collection.

Generally speaking, the problem c farmers, their outlook and apparatus, is severe as has been met in the developm bulking dry farm produce, simply becausi is considerably more national and re organization and mutual aid in dairy tl arable farming. This stems, of course, fr( Milk Marketing Board, which, although Government Department, could well be s relation to its influence over everyone et in the milk business.

It would be fair to say (but contradicta anyone with an axe to grind) that son like 90 per cent, of the progress in milk merit over recent years is due directly M.M.B. Criticizable it may be on some but in terms of bulk at least it has bee gressive; bold even beyond its tert reference, perhaps.

us is certainly true where collection in bulk incerned.. What has been done so far has done almost entirely by the M.M.B. What 'uture really holds—and what it will cost— e Board's secret. They are not inclined to not even, one feels, to take a slightly ponsible but probably harmless dip into Future just for fun. But the following basic i might provide an exercise in reading teen the lines.

le M.M.B. instigated bulk collection of milk i farms with eight producers in the 'bury, Berks, area in February, 1955. This very much a pilot project. A second me began in the Midlands in 1957, and by I the Board was satisfied that bulk collechad gone beyond the experimental stage.

t the end of 1960 10 Board schemes were peration, involving 200 farm tanks and an .oximate daily total of 27,500 gallons. By beginning of September, 1961, a further schemes were being operated on Board IS, and in the course of just one year, taking account the extension of existing schemes, number of farm tanks and the gallonage nearly trebled.

t the moment the Board is moving 108,000 gallons. of milk daily from 731 farm tanks to dairies. Target gallonage for the 26 bulk-collection schemes now in operation is 189,000 gallons.

Another seven schemes are scheduled to begin during the first quarter of this year. The expected daily gallonage for these is just over 40,000.

Impressive as these figures are, it has to be understood that bulk collection is as yet only skimming the cream, so to speak. Total milk collection from farms in England and Wales at present runs into 5.2 million gallons from 120,000 farms per day, of which 98.5 per cent. is sfill handled in churns carried on flats by the Board, by dairies themselves and by vehicles operated by professional hauliers.

Nevertheless, the growth of bulking since mid-1960 speaks for itself, and may reasonably be held to speak optimistically for the future, particularly the long-term future. It is this—the long-term future—in which hauliers are, of course, likely to be interested. So far, other than very oceasionatly where the local dairy and farms lend themselves to bulk collection, hauliers have not been unduly backward in coming forward, even though a 1,750-gallon tanker suitably equipped costs something around £4,500.

Assuming the sort of development inherent in the M.M.B. figures, however, interest is likely to grow over the next few years. Anticipating this, and in order to get some sort of picture of the practical aspects of bulk milk collection, by the courtesy of the M.M.B. I spent a day recently on a fairly newly established collection round operating out of the Dorking, Surrey, M.M.B. depot, and supplying the Express Dairy in Morden.

Driving Personnel

One of the problems immediately apparent is that of driving personnel. A man collecting churns on a flat requires little more than his driving ability, a certain amount of strength, knowledge of his run, and the goodwill of the farm personnel. The bulk collection driver has to be more of a technician. He needs a fairly high 'degree of driving skill to negotiate many of the difficult entries both to farms and farmyards (which look like remaining one of the major problems of the system, especially in winter). Additionally he needs knowledge of the equipment and techniques used in collecting milk by bulk; and he also needs some knowledge of milk itself, the processes through which it passes, and the circumstances under which its condition is likely to be adversely affected. Above all, perhaps, he needs to be a responsible individual, and one with a fairly highly developed sense of hygiene.

To date, due to the comparatively limited development of the scheme, the M.M.B. have been able to take men from churn collection and train them as bulk collectors without much difficulty. Obviously the most suitable type of driver has been selected from a fairly wide availability. But, quite apart from a possible decrease one day in the number of suitable personnel, the drivers' outlook on the job could raise problems.

Not all churn men, it seems, have a desire to go bulking. Although the tanker operator is paid a little more money, usually wears a better uniform and undoubtedly achieves a higher working status than the churn collector, many drivers see disadvantages in the•job, which a small amount of extra pay is probably insufficient to. outweigh.

These include at present a considerably greater " dead" mileage than on churn collection, where a service is genetc18 ally a series of short hops; the need for fairly prolo mental application to a greater and more complex s of tasks, plus an overall increased responsibility an necessity sometimes to be able to make rather decisions.

In some cases it just doesn't appeal. Where it does: the driver has' completed a careful training and is act on the job there would seem to be few complaints.

The training of a bulk milk tanker driver norr takes between six and eight days, but can be reduc( four in the case of an apt pupil. It is carried out in instances by the M.M.B. itself, in others by the EL which the depot supplies.

What is the driver trained to do?

An account of my day actually spent on a colic round will probably give the best picture.

Driver Bell and I left porking depot at 7.45 a.m. round to be completed at the Express Dairy in Mc between 5 and 6 p.m. The vehicle was a standard A Clydesdale 8-tonner; the tank a 1,750-gallon two-corn ment insulated stainless-steel unit made and equippe Darham Industries, Ltd.

One of the problems inherent in bulk milk collecti that of loading the milk. Stainless steel gear pi operated by power take-off have been extensively However, the Board have considered the vacuum sY. and this was the collection technique on the vehicl which I travelled.

Here an electrically driven exhauster runing off C.A.V. alkaline batteries is used to induce a vacuum i compartments, The tank is then coupled to the farm the inlet, valve in the external pipework is opened (this into the two raised hatches mounted on top of the with appropriate shut-offs), and the milk is sucked hit required compartment. Another advantage of this s3 in terms of maintaining the condition of the milk is it runs down the tank wall from the top, as against f feeding through itself as happens if loading is not thr the .top.

Only real drawback to the vacuum system—apart cost—would seem to be the necessity for a heavier stiffened tank. Operationally the system is quick, and, short of the exhauster failing, virtually foolproc

On starting, before his calls, the driver's first task switch on the exhauster, which then operates under matic control. By the time he is ready to load the batch of milk the vacuum in the -tank is up to its des value.

The first actual routine task on arrival is to open th of the farm tank and inspect the milk, and this is wh certain amount of responsibility not inherent in collection rests with the tanker operator. During his le is taught enough about milk to recognize andition, within broad limits, by the look of id by its smell. The colour of the milk of particular round varied between off-white a distinct cream (due generally to the herd he feed), but it is a pinky tinge that the ator has to beware of. Thisindicates blood ie milk, in which case he is not allowed to it The same applies if he is not satisfied ie odour of the milk.

either case the driver, whatever the pressure Lim, must not take the milk. It is his duty !lephone eithei his manager back at the

I, or, if he is not available, the dairy. The ier then arranges to send out churns and a• ible pump. The milk is then examined at fairy in the usual manner.

Dip-stick Reading

'suming that the smell and colour of the satisfy the operator, his next step is to take lip-stick reading in the farm tank. This is with the milk in an absolutely still condiand is usually in this condition by the time rrives.

le dip-stick reading is taken twice if there y doubt about the first reading. This is a : rule of the job. The calibrated reading le dip-stick is then read-off against a chart ie farm dairy which gives the gallonage. temperature of the milk is then taken from ank thermometer, and the dip reading, the nage and the temperature are entered in a Pt book which the driver signs. Receipts in triplicate. One copy is left with the er, one goes to the dairy and the third to aulier.

c temperature of the milk in the farm tank 'variably between 36 and 40 deg. F. nigh the collection tankers are not refrige, even on the hottest of days on the longest Junds the temperature rarely rises more two degrees, which means that the milk is )aded at the dairy well below a temperature iich it could begin to be adversely affected. river Bell's ease, the milk in his tank was 'ally off-loaded at 39 deg. F.

ving completed his readings and his receipt, perator switches on the tank agitator and, ! the milk is astir, couples the rubber loadlose (carried in an alloy trough alongside ink, the aperture protected by a screw-on with the farm tank. This is a straightIrd operation effected by a simple screw log, standardization having been achieved niplings although not in types of farm

e next step is a vital one, and a task in once again a sense of responsibility and cation to the job and the rules are called Before loading, and while the milk is ing, the driver takes a sample. The dairy de the equipment for this. It comprises rubber-corked and labelled bottles, with of which goes a small long-handled metal Each ladle is used to take only one le. The ladle is filled, and the milk is transto the bottle well away from the tank, so there is no danger of spilt milk running (Continued on page 830)