A Fully Automatic Gear-control System

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

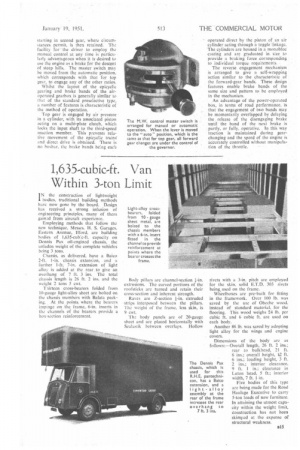

Epicyclic Gearbox with Electro-pneumatic Valves Actuated by Centrifugal and Throttle Governor to Provide Fully Automatic Control

FULLY automatic transmissions for road vehicles have often been FULLY

with unescapable disadvantages, such as departure from standard practice in the design of the gear-change mechanism and the obligatory adherence to a gearchanging technique which may be unsuitable for certain local conditions. Two valuable features of the M.W. automatic control, recently' introduced by the Self-Changing Gear Co., Ltd.. Lythalls Lane, Coventry, completely overcome these objections.

The system may be superimposed on any of the concern's power-operated _ boxes of the non-preselective type, and by changing the contour of cam plates . in the governor, any desired speedtorque characteristic may be obtained. For example, it is possible to provide a characteristic approximating to that of a torque converter or a diesel-electric drive; alternatively the control may be adapted to kick-down change operation. Full manual control is available at any time without stopping the vehicle, the change-over being controlled by a master switch.

The design of the air-operated gearbox is based on the company's railcar unit, which has had a long and successful history. It has separate air cylinders for each speed, which are controlled by valves fed from an airpressure line.

The system is electrically operated and essentially comprises a master switch, a governor driven by the gearbox input shaft, a series of electropneumatic valves and control panel. With the master switch in the automatic position, the governor transmits art electrical impulse to the appropriate valve solenoid according to the speed of 614 the input shaft and the degree of throttle opening. •

When accelerating from a standing start on a small throttle opening, as when descending an incline, the higher ratios are engaged at comparatively low engine speed. If, on the other hand, the throttle be kept fully open, engagement is delayed in each instance until a comparatively greater speed has been attained. Changing-down is controlled in a like manner, a full-throttle change being made at a considerably higher engine speed than a part-throttle change. At any given throttle opening there is a speed range during which neither a change-up nor a change-down is possible, the extent of the range depending upon the pre-determined governor, characteristic.

The centrifugal weights of. the governor react on the radial tracks of • a sliding member against spring pressure and impart an axial movement to a. push-rod. The geometry of thi mechanism is such that, whereas the centrifugal force of the weights varies as the square of the rotational 'speed, the displacement of the rod is proportional to the speed. This simplifies the design of the electrical-contact gear ' which is actuated by the rod.

With an increase in speed, an inverted V-shaped arm, at the end of which are two contact points, is turned progres

sively through an arc of a circle. Between the points is a rotationally movable member carrying two contoured plates which are separated from each other and insulated. The operating shaft of this member is linked to the throttle pedal.

Both the arm and the cam member move in an anti-clockwise direction from the closed position. When the left point makes contact with the cam, current is transmitted through an automatic selector switch on the control panel to the appropriate electropneumatic valve for a change-up. Similarly, contact of the point at the right causes a change-down to be Made.

The automatic' selector switch distributes the current from the governor to the appropriate air-valve solenoid. A change-down and a change-up relay arc mounted on the controlpanel and these actuate two electro-magnets which . turn the distributor spindle in the required direction by means of a ratchet mechanism: Further relays are employed between the ay/itch and the windings of . the electro-pneumatic valves, which coMprise simple, electromagnets operating against spring pressure.

`Irlequired, thc rans,,:Of automatic control may be restritecg* the three

• roic* b-y, m ving igsVitch on the

control paneLa be-4* al practice of

starting in second gear, where circumstances permit, is then retained. The facility for the driver to employ the manual control at any time is particti. lady advantageous when it is desired to use the engine as a brake for the descent of steep hills. The master switch may be moved from the automatic position, which corresponds with that for top war, to engage any of the other ratios.

Whilst the layout of the epicyclic gearing and brake bands of the airoperated gearbox is generally similar to that of the standard preselective type, a number of features is characteristic of the method of operation.

Top gear is engaged by air pressure in a cylinder, with its associated piston acting on a multi-plate clutch, which locks the input shaft to the third-speed reaction member. This prevents relative movement of the epicyclic trains' and -direct drive is obtained. There is no husbar. the brake hands being each operated direct by Ihe piston of an air cylinder acting through a toggle linkage. The cylinders are housed in a. monobloe casting and are graduated in size to provide a braking force corresponding to individual torque. requirements.

The reverse engagement mechanism is arranged to give a self-wrapping action similar to the characteristic of the forward-gear bands. These design features enable brake bands of the same size and pattern to be employed in the mechanism.

An advantage of the power-operated box, in terms of road performance, is that the engagement of two bands may be momentarily overlapped by delaying the release of the disengaging brake until the band of the next brake is partly, or fully, operative_ in this way traction is maintained during gearchanging and the speed of the engine is accurately controlled without manipulation of the throttle.