An Improved Reamer for Use in Boring Machines.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

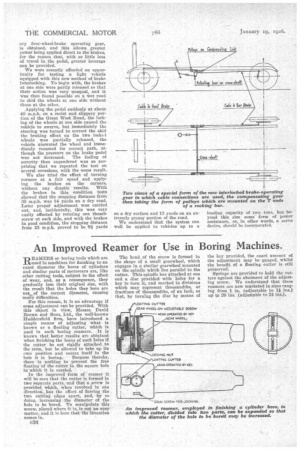

REAMERS or boring tools which are used in machines for finishing to an exact diameter the bores of cylinders and similar parts of motorcars are, like other cutting tools, subject to the effect of wear, and, as a consequence, they gradually lose their original size, with the result that the holes they bore are not of the correct diameter, causing many difficulties.

Vor this reason, it is an advantage if some adjustment can be provided. With this object in view, Messrs. David Brown and Sons, Ltd., the well-known Huddersfield firm, have introduced a simple means of adjusting what is known as a floating cutter, which is used in such boring reamers. It is known that better results are obtained when finishing the bores of such holes if the cutter be not rigidly attached to the stem, but be allowed to take up its own position and centre itself in the

hole it is boring. Because thereby, there is nothing to prevent the free floating ofthe cutter in the square hole in which it is carried.

In the improved form of reamer it will be seen that the cutter is formed in two separate parts, and that a screw is provided which, when revolved in one direction, has the effect of forcing the two cutting edges apart, and, by so doing, increasing the diameter of the hole to be bored. To manipulate this screw, placed where it is, is not an easy matter, and it is here that the invention comes in.

036

The head. of the screw is formed in the shape of a small gearwheel, which engages in a similar gearwheel mounted on the spindle which lies parallel to the cutter. This spindle has attached at one end a disc provided with holes for a key to turn it, and marked in divisions which may represent thousandths, or fractions of thousandths, of an inch, so that, by turning the disc by means of

the key provided, the exact amount of the adjustment may be gauged, whilst the benefit of a floating cutter is still preserved.

Springs are provided to hold the cutters against the abutment of the adjusting screw. We understand that these reamers are now marketed in sizes ranging from 1 in. (adjustable to 1* ins.) uP to 20 ins. (adjustable to 24 ins.).