MAKING BEST USE OF THE FORD.

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck, we endeavour to deal with the subject from every viewpoint, so that the advice will appeal to the owner, driver, maintenance engineer and mechanic.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will .make suitable remuneration for any which are published.

381.—Supporting a Crankshaft While Fitting Bearings.

Sometimes, when fitting big-ends to crankshafts, the holding of the shaft is found to be very awkward, particularly if only one vice be available.

A good way of supporting the crankshaft in such circumstances is to obtain a board approximately 3 ft. long, S ins, wide and 1 in. thick, and bolt or screw this board to the bench close to the vice. Then drill two holes in the board and bolt the crankshaft to it by means of the flange for the flywheel.

Now obtain a second piece of wood, 3 ins. sq. and rather longer than the first board. Measure the distance between the floor and the upper portion of the front part of the crankshaft and cut the woodI in. longer than this measurement. .4.1. V cut should then be made in the top part of the wood support, and the support wedged under the crankshaft, which will thus be kept quite firm and without utilizing the vice at all.

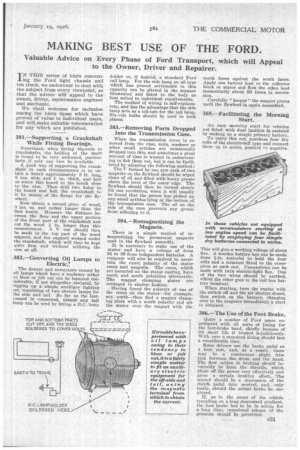

382.—Converting Oil Lamps to Electric., The danger and annoyance caused by oil lamps which have a tendency either to blow or jolt out can be lessened considerably, if not altogether obviated, by rigging up a simple auxiliary lighting set, consisting of two electric lamps for the side and tail. So far as the lastnamed is concerned, alniost any tail lamp can be used by fitting a B.C. lamp

holder or, if desired, a standard Ford tail lamp. For the side lamp an oil type which has proved serviceable in this capacity can be altered in the manner illustrated and fitted to the body as best suited to individual requirements.

The method of wiring is self-explanatory, and has the advantage that the side lamp acts as a tell-tale for the tail lamp. Six-volt bulbs should be used in both places.

383.—Removing Parts Dropped Into the Transmission Case.

When the transmission cover is removed from the case, nuts, washers or other small articles are occasionally dropped into this, and sometimes a great amount of time is wasted in endeavouring to fish them out, but it can be facilitated by adopting the following method : The V formed by one arm each of two magnets on the flywheel should be wiped clean of oil and filled with 'heavy grease above the level of the outer edge. The flywheel—should then be turned slowly for one revolution, when it will usually be found that the grease has picked up any small articles lying at the bottom of the transmission case. The oil on the side of the case prevents any grease from adhering to it.

384.—Remagnetizing the Magnets.

There is a simple method of remagnetizing the permanent magnets used in the flywheel assembly.

It •is necessary to make use of the stator and have a voltage of from 24 to 30 from independent batteries. A compass will also be required to ascertain the exact polarity of the stator cores and magnets. The cores, which are mounted on the stator casting, have north and south polarities alternately. The magnet clamping plates are arranged in similar fashion.

Flaying found the polarity of one of the cores on the stator—for example, say, north—then find a magnet clamping plate with a south polarity and set the stator over the magnet with the north faces against the south faces. Apply one battery lead to the collector block or stator and flick the other lead momentarily about 50 times in succession.

Carefully " keeper " the magnet plates until the flywheel is again assembled.

385.—Facilitating the Morning Start.

An easy morning start for vehicles not fitted with dual ignition is assisted by making up a simple primary battery.

To carry this out, Purchase four dry cells of the electric-bell type and connect these up in series, positiv6 to negative This will give a working voltage of about five. A wooden battery box can be made from t-in, material to hold the four cells and a terminal fitted to the crosspiece at each end. Connections can be made with twin electric-light flex. One of the two wires should be earthed, whilst the other goes to the coil box battery terminal.

When starting, turn the engine with the switch off and the air shutter closed, then switch on the battery, changing over to the magneto immediately a start is obtained.

386.—The Use of the Foot. Brake.

Quite a number of Ford users experiment with all sorts of lining for the foot-brake band, chiefly because of its short life if treated injudiciously. With care a standard lining should last a considerable time.

Some drivers use the brake pedal as a foot rest, and, as a result, there May be a continuous slight Inc. tiefl between the drum and the band. The first action in braking should invariably be from the throttle, which shuts off the power very effectively and gives acertain braking effect. The second should be a depression of the clutch pedal into neutral, and, only lastly, should the actual brake be empl oyed.

If, as in the event of the vehicle travelling on a long downward gradient, the foot brake has to be in action for a long time, occasional release of the pressure should be permitted.