Drop 11-frame moves closer

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

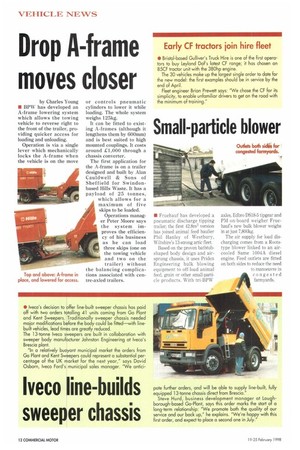

by Charles Young • BPW has developed an A-frame lowering system which allows the towing vehicle to reverse right to the front of the trailer, providing quicker access for loading and unloading.

Operation is via a single lever which mechanically locks the A-frame when the vehicle is on the move or controls pneumatic cylinders to lower it while loading. The whole system weighs 125kg.

It can be fitted to existing A-frames (although it lengthens them by 600mm) and is best suited to high mounted couplings. It costs around £1,000 through a chassis converter.

The first application for the A-frame is on a trailer designed and built by Alan Cauldwell & Sons of Sheffield for Swindonbased Hills Waste. It has a payload of 25 tonnes, which allows for a maximum of five skips to be loaded.

Operations manager Peter Moore says the system improves the efficiency of his business as he can load three skips (one on the towing vehicle and two on the trailer) without the balancing complications associated with centre-axled trailers.