HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

486.—Improving the Vulcan Radiator Suspension.

In certain instances trouble has been experienced with the honeycomb radiator fitted to the 30-cwt. Vulcan.

The radiator proper is carried in an aluminium shield and secured to this by four i-in; setscrews, which are inserted into four lugs on the shell. The threads of these logs sometimes strip as the result of vibration.

This trouble may be cured by drilling I'd -in. diameter holes right through the shell so that they come out on the curve. Aluminium solder should then be applied at the point where the holes break through the shell, and this solder cut down to make beds for the bolt head& Four bolts must be specially turned down as illustrated.

Reference to the drawings will show the old and new methods of fitting as applied to one bolt only.

487.--The Inspection of Gearboxes.

It pays hit the end to take the cover off the gearbox from time to time and closely to inspect the gears.; while doing this pull the gear lever into each respective gear in turn and take particular notice if the teeth mesh correctly. If not, it will usually be found that the gears can be • adjusted, or, possibly, the Sliding forks are unduly worn, m which case they must be replaced or repaired.

Several methods 'havealready been described pointing out how such repairs can be effected. One method is to build them up by welding and then to replace them. In any case, any appreciable slack should be seen to as soon as possible, as, when the, gear teeth are only partially in mesh and have to take a heavy load, they will not stand up to the work very long.

The bearings should also be closely watched for wear. If they are plain--although these are now unusual—and are worn, the teeth will not mesh properly an the pitch circles. If ball bearings are utilized the slightest play should be treated with anspicion, as, once play occurs, they soon break up. At the same time' tighten any loose housing caps and fit fresh joints if any leaks occur through the caps or the cover.

Remember that it is always far easier to take up a small amount-of slack or to fit a new bearing when needed than to have the whole gearbox smashed up and a towing jab necessitated. Occasionally wash out the box with paraffin, cleaning out all the old grease, as small particles of metal are constantly being knocked or worn off the teeth and form a kind of grinding paste which accelerates wear, particularly in the ball bearings. Care should be taken to use gear oil or grease recommended by the makers. The leading oil companies publish charts showing the correct lubrication. If a lot of grease leaks from the bearings it may be advisable to use a slightly thicker grade of oil than that formerly employed.

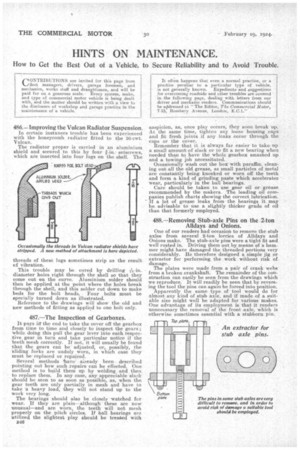

488.—Removing Stub-axle Pins on the .2-ton Alldays and Onions. •

One of our readers had occasion to remove the stub axles from several 2-ton lorries of Allclays and Onions make. The stub-axle pins were a tight fit and well rusted in. Driving them out by means of a hammer might have damaged the threaded portions very considerably. He therefore designed a simple jig or extractor for performing the work without risk of damage. The plates were made from a pair of crank webs from a broken crankshaft. The remainder of the construction can easily be seen from the drawings which we reproduce. It will readily be seen that by reversing the tool the pins can again be forced into position. Apparently the same type of tool would do for almost any kind of stub axle, and if made of a suitable size might well be adapted for various makes. One advantage of its employment is that it renders unneceasary the removal of the front axle, which is otherwise sometimes essential with a stubborn pin.