Germany's Premier Motor Works.

Page 2

Page 3

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

A Visit to the Factory where MiInes-Daimler Chassis are Constructed.

It was the Editor's privilege, in December last, to enjoy a visit to both the Marienfelde and Unterturckeim works of the Daimler Motoren Gesellschaft, in company with Mr. H. G. Burford, M.I.Mech.E., managing director of Milnes-Daimler, Limited, and -a member of our editorial staff has during the past week, been over the first-named works. We are obliged, in presenting some notes on these visits, to defer to the wishes of the gentlemen who have twice thrown open their works for our inspection in every detail, and to refrain from entering into descriptions of particular processes and special trade practices, not a few of which are peculiar to the Marienfelde works, with which we are now concerned. It must suffice that the fruits of these manufacturing methods are enjoyed by hundreds of users in this country, who have, in their own experience, proved the lasting qualities of the finished product.

Marienfelde is a suburb of Berlin, and the manufacturing works cover a total area of 67,400 square yards, of which 21,600 square yards are covered with buildings, whilst another 2,000 square yards have been utilised for the laying down of a track. The separate repair works occupy, strangely enough, the same area as that of the track, but they are on an adjoining estate which has a total area of 70,800 square yards, and have their own track for testing purposes. An underground passage leads from Marienfelde station directly to the factory grounds, so that the employees enter and leave the works direct, the various time clocks, weighbridges, and the first-aid departments being alongside the porter's lodge.

A splendid set of administration buildings has been erected, as may he gathered from the illustration at the foot of this page. Board, reception, meeting rooms, general offices, and the central telephone station occupy the ground floor. The first floor is devoted to the drawing and designing offices, the accountancy and wages departments, and the managerial and order offices. In the basement, one finds a boiler installation for the heating of these buildings and a section of the factory, whilst the top floor of the house is utilised for storage purposes. Passing through the administration buildings, one comes to the dispatch and forwarding departments, in the inner courtyard of which is a good loading stage conveniently situated.

A Spacious Main Shop.

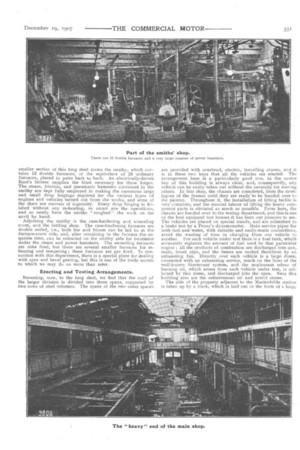

One enters next, the main shop of the factory, which has a ground area of 10,450 square yards_ Round this building there are galleries, in which are housed the automatic and lighter machine tools, and it is equipped with two, powerful, electric, overhead travelling cranes of 5 tons and 7 tons capacity respectively. The construction of the roof of this building is of a saw-tooth type, one slope being covered with glass, and the opposite slope being of concrete with a double layer of waterproof paper roofing. The building is very light and is extremelywell ventilated by Scharowski patent ventilators. For checking the brilliant rays of the sun during hot weather, the shop is provided with suitable awnings. The whole of the floor space is concreted, and wooden grids are provided at all places where workmen are stationed. As far as the heating of the building is concerned, there is ample provision from the boiler installation in the basement to which we have already made reference above.

Starting from the top end of the main shop, we find the heavier of the machine tools, and a large surface plate, which is 20 feet long by 8 feet wide ; several smaller surface tables are also to be found in this section of the building. The other half of this large shop contains the vertical and horizontal turning and boring mills, and various other milling machinery, a large battery of Gisholt turret lathes, semi-automatic turret lathes, slotting and shaping machines, and the grinding department. This latter department is particularly well equipped, numerous disc and spindle grinding machines, representing some of the finest patterns produced in the world, being in place. Many of these have been specially designed for the purpose for which they are employed, and amongst these must be mentioned some little grinding machines for dealing with countersunk and twist drills. Amongst the milling machines we noticed several fine examples of the universal and double-spindle type. The gear-cutting department, which forms part of this branch of the main shop, is well equipped with milling and shaping machines for both spur and bevel gearing, as well as with several examples of the latest "tooth generating" machines. The vertical boring mills, to which we have made reference, are chiefly used for the large-diameter heavy parts, such as flywheels, road wheels, and pulleys for stationary motors, a large number of which are turned out from these works. The horizontal boring mills, of course, are chiefly used for boring cylinders. The cleanliness and order here, as everywhere else in the building, is one of the most distinguishing features ; shavings and chippings from the various machines are on no account allowed to accumulate on the machines, but are quickly removed and placed in centrifugal " separators," and the separated oil is drained off, filtered and used again. The machinery is arranged in groups and is electrically driven.

All foremen's offices are most conveniently placed, and are elevated so as to give to each foreman the best possible chance of efficient supervision.

An annexe was added to this main shop during 1905 and 1006, and-this addition is separated from the older portion by a wall, through which large arched openings have been made, in order to allow of free passage from the one to the other. This annexe is divided into four sections, in the first of which is another large battery of vertical and horizontal boring machines and milling machines for special purposes. The second is devoted to the erecting of stationary and portable engines, in which alcohol-driven motors the company does a huge business amongst agriculturists. The third is occupied by small machine tools especially required for motor-vehicle engines ; and the fourth section is devoted to the manufacture of the necessary tools and jigs required throughout the works. In the right-hand gallery of this annexe, the vehicle and marine motors are assembled, and the left gallery is devoted to the fitting of gearboxes and differential countershafts.

The Forge Equipment.

Parallel to the main shop, but a distance therefrom of 40 feet, there is a long shed which is divided into two sections. These are separated by a gangway 15 feet wide, and in this gangway is placed a weighbridge, whilst over the roof of the gangway is a large water tank of about 42,000 gallons capacity. The

smaller section of this long shed forms the smithy, which contains 12 double furnaces, or the equivalent of 24 ordinary furnaces, placed in pairs back to hack. An electrically-driven Root's blower supplies the blast necessary for these forges. The steam, friction, and pneumatic hammers contained in the smithy are kept fully employed in making the numerous large and small drop forgings required for the various types of engines and vehicles turned out from the works, and some ot the discs are marvels of ingenuity. Every drop forging is finished without any re-heating, so smart are the operations, and so neatly have the smiths "roughed " the work on the anvil by hand.

Adjoining the smithy is the case-hardening and annealing room, and the fettling shop. The case-hardening furnaces are double ended, i.e., both bar and bloom can be fed in at the furnace-room side, and, after remaining in the furnace the requisite time, can be extracted on the smithy side for treatment under the steam and power hamMers. The annealing furnaces are coke fired, but there are several smaller furnaces for reheating and tempering ; these furnaces are gas fired. In connection with this department, there is a special plant for dealing with spur and bevel gearing, but this is one of the trade secrets to which we may do no more than refer.

Erecting and Testing Arrangements.

Reverting, now, to the long shed, we find that the roof of the larger division is divided into three spans, supported by two rows of steel columns. The spans of the two outer spaces

are provided with overhead, electric, travelling cranes, and it is in these two bays that all the vehicles are erected. The arrangement here is a particularly good one, as the centre bay of this building is always clear, and, consequently, any vehicle can be easily taken out without the necessity for moving others. In this shop, the chassis are completed, from the riveting-up of the frames until they are ready to be handed over to the painter. Throughout it, the installation of lifting tackle is very complete, and the manual labour of lifting the heavy component parts is obviated as much as possible. From here, the chassis are handed over to the testing department, and this is one of the best equipped test houses it has been our pleasure to see. The vehicles are placed on special stands, and are submitted to a brake test by a Prony's dynamometer. Main service pipes for both fuel and water, with suitable and easily-made connections, avoid the wasting of time in changing from one vehicle to another. For each vehicle under test there is a fuel tank, which accurately registers the amount cif fuel used by that particular engine; all the products of combustion are discharged into one, main, trunk pipe, and the fumes are sucked therefrom by an exhausting fan. Directly over each vehicle is a large dome, connected with an exhausting service, much on the lines of the well-known Sturtevant system, and the unpleasant odour of burning oil, which arises from each vehicle under test, is collected by this dome, and discharged into the open. Near this building also are the subterranean oil and petrol stores.

The side of the property adjacent to the Marienfelde station is taken up by a track, which is laid out in the form of a loop, and has various gradients and curves. It is constructed of asphalt, on a foundation of concrete, and on this track all the vehicles constructed in these works are tested.

Goods Inward.

Between the annexe and the erecting shed there is a space some 36 feet wide, which is covered in by a simple, galvanised. ironand glass roof. The space under this roof is used as a store for bar iron and steel, and the raw material required for use in the foundry, as well as sheet and plate steel used for the making of the frames and other parts. Within this enclosure, the necessary cold saws and cutting-off machines are accommodated, and the location of this store is such that material can be handed to either the smithy, erecting shop, or the main shop, with the least possible delay. All material is, of course, checked as received into this store, the stores office being well placed and equipped with an efficient staff for the control of this important department, which receives practically the whole of the raw material required by the works.

The Power Houses.

The power house stands at a distance of 30 feet from, and is parallel with, the main building, being in close proximity to the railway sidings. It is divided into three sections: (a) engines and dynamos ; (b) gas generators ; and (c) boilers. The equipment of the engine room comprises two double-cylinder engines of 185h.p. each, one double-cylinder engine of 325h.p., and one duplex, twin-cylinder engine of 600h.p. In some cases these engines are directly coupled to generators, whilst in others the generator is belt driven. Free to traverse over the whole of this room is an electric, overhead travelling crane, capable of dealing with six tons. All the necessary water and, gas pipes for the cooling of, and supply to, the engines, and all electric cables, are carried through the floor to a vaulted chamber. By this arrangement the floor space is left clear and uninterrupted by a tangle of piping, which is not only unsightly, but is generally a source of danger in any engine room. The generators supply current at 220 volts to both the lighting and power circuits, which extend throughout the whole of the works.

In the gas-generator section of the power department, there are four suction-gas plants, whose capacities are 200, 260, 400, and 600h.p. respectively. These generators are built into chambers below the floor level, in order that the anthracite may b: fed into the generators from the floor level, without the necessity of hoisting the fuel to any considerable height. The water which is used in the gas scrubbers, after being drawn off at the bottom, is pumped up to a filter bed, in connection with the works sewerage scheme, and, before passing to the town sewers, all tar deposits and other impurities are extracted.

It may be noted that the company has its own water supply in the form of two wells, from which the water is lifted by electrically-driven, three-plunger pumps. The water-service mains extend to every department of the works. In the event of failure of the supply from the wells, connection is made to the mains of the Charlottenburg water works.

In the boiler room there are two large double-furnace, watertube boilers for supplying the steam hammers, and for heating purposes. These boilers are fired with lignite (brown coal), mixed with ordinary small coal. Near the test house there is a smaller auxiliary power station, equipped with a two-cylinder ergine, direct coupled to a 30-kilo watt generator. This auxiliary power plant is provided in case of failure of the main generating plant, and is sufficient to enable the _ptincipal machines to be kept running while the necessary repairs are being made to the main power installation. The railway sidings are particularly well arranged ; all goods can arrive by rail from Marienfelde station, and arrangements ate provided for shunting the various loaded trucks to: (a) the subterranean oil and petrol stores; (b) the stores in which are kept the turnings and chippings from the machines; (c) the coal hunkers ; and (d) various other stores in different parts of the works.

Care of the Men.

There is an excellent suite of kitchens and dining rooms, with accommodation for both officials and workmen, and an interesting feature about this is that there are separate dining-rooms for married and unmarried men.

The charitable institutions in connection with the works of this eompany are quite a: feature. These include a provident fund for assisting workmen and their families in the event of illness, and the capital of this fund is derived from the proceeds of the lease of the catering department, fines levied on workmen, and voluntary contributions and donations ; it is further assisted from the workmen's premiuth fund, which consists of contributions received from payments for drivers' certificates granted„.by the technical director of the works. Out of this latter fund, premiums are paid to workmen and fitters for meritorious work. There is also an institution for providing nursing assistants at the homes of workmen in case of illness. The administration frequently buys provisions and fuel in very large quantities, which are then retailed to the men and officials at cost prices ; in fact, everything possible is done to insure the welfare and comfort of the men, both at the works and in their homes. The works normally employ 1,300 men, whilst the administration department accounts for another 120.

The technical director of the works, Mr. P. Spranger, and the commercial director, Mr. Schippert, take the greatest personal interest in all that concerns the company's progress, and we were particularly struck with the wisdom of their being provided with comfortable residential quarters within a stone's throw of the works entrance. Director Spranger laid out and erected the Marienfelde works after a study of the latest and most up-to-date practice of Europe and America.