A PRACTICAL FORM OF SPRING WHEEL.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

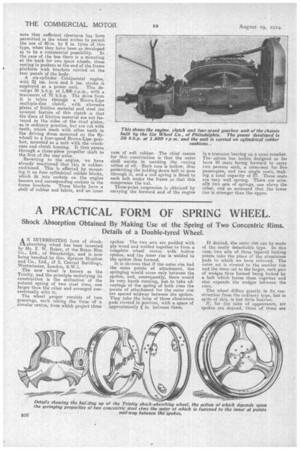

Shock Absorption Obtained By Making Use of the Spring of Two Concentric Rims. Details of a Double-tyred Wheel.

AN INTERESTING form of shockabsorbing wheel has been invented by Mr. F. W. Baker, of the Baker Rim Co., Ltd., of Stonrbridge, and is now being handled by Geo. Spencer Moulton and Co., Ltd., of 2, Central Buildings, ;Westminster, London, SAVA.

The new wheel is known as the Trinity, and the principle underlying its construction is the utilization of the natural spring of two steel rims, one larger than the other and arranged concentrically with it. The wheel proper consists of two pressings, each takine. the form of a circular centre, from Which project three

spokes. The two sets are padded with ply wood and welded together to form a complete wheel centre with hollow spokes, and the inner rim is welded to the spokes thus formed.

It is obvious that if the outer rim had the same points of attachment, the springing would occur only between the spokes, and, consequently, there would be very harsh running, but to take advantage of the spring of both rims the points of attachment for the outer rim are spaced midway between the spokes. They take the form of three aluminium pads riveted in position, with a space of approximately in. between them. If desired, the outer rim can be made of the easily detachable type. In this case, two sets of three tapered locking pieces take the place of the aluminium pads to which we have referred. The outer set is riveted to the smaller rim and the inner set to the larger, each pair of wedges thus formed being locked by a bolt which forces them together and also expands the wedges between the rims.

The wheel differs greatly in its construction from the ordinary type, but in spite of this is but little heavier.

If, for the sake of appearance, six spokes are desired, three of these are

actually dummies, being cut short just inside the inner rim

Another wheel presenting many features of interest has been patented by M. Donoghue and Sons, Ltd., of Llanelly. This wheel is so arranged that two tyres can be used, one being fitted over the other, and in addition to this an extra-stout tube with a thickness of nearly ;If in. is employed to prevent any risk of pinching, whilst an extra valve of special type forms part of the oiltfit.

In this wheel either new or secondhand outer tyres can be used, according to requirements. In many cases large covers, which have been discarded owing to broken beads, cracked canvas or side bursts, can be utilize&

The device consists of a pair of steel or aluminium discs, corrugated to prevent buckling, and fixed to the usual form of spoked wheel by bolts passing right through this wheel and the two discs. The groove at the edge of each disc forms a rim into which fits the respective bead of the upper tyre, so that this is held in a vice-like grip which prevents any movement of one tyre over the other.

In the case of a 30-in. by 31-in. tyre, i.e, the Ford size, the cost for making the alteration to each wheel is £2 17s. fid., including carriage. This includes the discs at £2, the extra valve to fit over the usual one, costing 2s., and the special inner tube, for which 15s. 6d. is charged. Other sizes can be dealt with, and information regarding these can be obtained from the patentees.

The chief stipulation as regards the inner tyres is that they should be quite sound, 'although the treads may be worn thin. As regards the outer tyre, this must always be an oversize. For in

stance, in the case of the Ford, tho outer tyre is 31 ins. by 4 ins.

In fitting, both tyres are placed together on the wheel, the lower tyre fitting as usual, whilst the upper one is disposed with its beads overlapping evenly at the sides. The inner tube is also inserted in the usual manner. The valve aperture in the discs is brought opposite tile valve and the discs bolted -together, it being ascertained while doing this that the beads fit evenly in the rimmed edges. The inner tube is then inflated to a pressure of 80 lb., and this pressure retained by fixing the extra valve over that normally employed.

We have not yet had an opportunity of testing this invention, but we are informed that the steering and petrol consumption are quite normal, and that users have, been well satisfied, whilst the smoothness of running is said to be unaffected.