A NEW PRACTICE IN CARBURATION.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

The Paterson Carburetter which Interchanges Temperature with Velocity of Mixture in Order to Secure Flexibility and Economy.

TELE SUBSTANTIAL interval of time since we dealt very fully, in our issue of August 30th, 1917, with the new principles in carburation embodied in the Paterson oil-fuel economizer does not by any means represent a wasted period—Mr. Paterson and his assistants are far too energetic for that

to have been allowed. . Up to the time when Mn Paterson left New Zealand, at the end of 1916, to place his invention before the home authorities as a 'useful means of effecting an economy in oil fuels, research work had been devoted by them to the elucidation of the problem of temperature control in carburation and to the development of the principle underlying that solution.

i The work n this country, from 1917 onwards, has been directed towards the simplification of the invention and bringing it down to a commercial proposition, whilst a number of trials of the system have been made in connection with different types of engines, and a great deal of data has been accumulated., Theresult of all this work is contained in the simple Means of applying the principle of temperature control, embodied in the new carburetter now in process of being manufactured in a range of sizes by the British company which has acquired the patent rights.

The importance of temperature control will increase as, time goes on, and as the use of the internal-combustion engine grows. , Within a short .20 years we have been compelled te lower our standard of suit. able gravity of spirit from .680 to about .735, introducing carburation difficulties which have increased With every increase of the specific gravity of the fuel supplied to us. Our fuels are no -longer homogeneous and, as the home-produced fuels and the results of cracking the heavier distillates come on the markets, our fuels will vary from week to week, and even between the supplies in one town and those in the next from which we fill our tanks. Our carburetters must be made more flexible and be brought into line to meet these conditions.

Increased fuel costs call for the adoption of every possible means of economising in fuel, and the best economy, from all points of view, is that which ensures complete volatility of the fuel and its complete combustion at any speed of the engine. No longer is it• permissible to use a carburetter which will give that result at only one critical speed of the engine, aa is. the case with the average carburetter, for, in such a case, any variation ia piston speed, resulting in a variation of compression temperature, sets up conditions of volatility which are unsuitable for the fuel, the observable effe,et3 being . pre-ignition of the fuel, pinking in the engine, or popping in the carburetter, whilst there is constant leakage of the unburnt fuel past the piston • rings, to the detriment of the lubricating oil.

Previous efforts to overcome these defects have been devoted to means for passing additional air into the of Paterson carburetter. combustion chamber at the engine speeds higher than that at which the carburetter is set to give its best result. But at en, gine speeds below the critical speed, fuel is wasted by reeondensation not only in. the induction pipe but even in the combustion chamber itself. The solution to the problem, as shown to us by the research work of the Patersons, is the use of heated air at low engine speeds when the velocity of the fuel charge is low, and by the use of cold air at high engine speeds Aen the velocity is high—in other words the inter-change of temperature and velocity. It had, previous to our description of the Paterson system of • temperature control two years ago, never been fully realized that temperature could be interchanged with • velocity so accurately that even heavy fuel oils (down to tar oils) could be volatilized without variation, in conditions of engine running that were quite inconstant.

One effect of imperfect carburation under variable running conditions is constantly being obtruded upon users and wayfarers. The latter observe it in the bombardment of the ear by popping and banging, as an engine is suddenly throttled down in traffic—it is a regular sound in the congestion of London traffic. The driver feels the effect (if he has tuned himself to

• suffer without a qualm the explosions on the carburetter side of the inlet valves and in the silencer) in the sluggishness of the engine to pick up. again when he opens the throttle. Ask the average driver, who knows his engine "well, quickly to swing the lever from full throttle to closed throttle and then to open throttle again, and he would hesitate to do it, because he knows the engine would respond badly. Yet, with the Paterson earburetter, we have done this and the engine has responded perfectly, accelerating and decelerating without sluggishness on the one swing or popping on the other. The effect can be gained with coal gas, because that ip a homogeneous fuel, but not when liquid fuel is being employed in an ordinary carburetter.

This result from the Paterson system spells flexibility in traffic and, moreover, economy of fuel. Taking a Ford which will do 18 to 20 rnilesto the gallon, the consumption with a Paterson carburetter, giving the flexibility described, has been reduced to a gallon per 29.6 miles. The London General omnibuses on which the canburetter has been tested have done a

it good 10 per cent, better consumption, whilst a 3-tan lorry in the fleet of one of the petrol companies has been doing 37.8 ton miles to the gallon.

The apparatus illustrated here materially, differs in form from that described by us two years ago, but

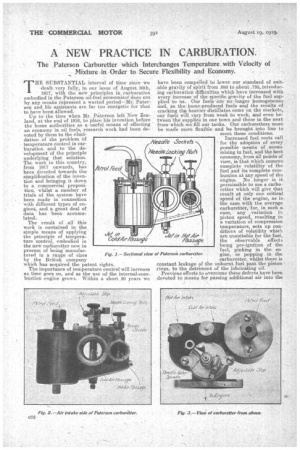

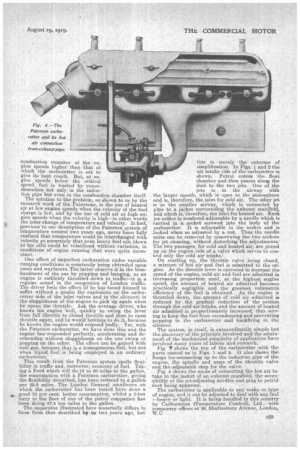

this is merely the outcome of simplification. In Figs. 1 and 2 the air intake side of the carburetter is shown. Petrol enters the float chamber and then passes along the duet to the two jets. One of the Jets is in the airway with the larger mouth, which is open to the atmosphere and is, therefore, the inlet for cold air. The other jet is in the smaller airway, which is connected by pipe to a jacket surrounding the exhaust manifold, and which is, therefore, the inlet for heated air. Each jet orifice is rendered adjustable by a needle which is carried in a socket screwed into the body of the carburetter. It is adjustable in the socket and is locked when so adjusted by a nut. Thus the needle units can be removed by unscrewing the two sockets for jet cleaning, without disturbing the adjustments: The two passages, for cold and heated air, are joined up on the engine side of a valve which serves to control only the cold air intake: On starting up, the throttle valve being closed, a mixture of hot air and fnel is admitted to the engine. As the throttle lever is operated to increase the speed of the 'engine, cold air and fuel are admitted in increasing proportion until, at the highest engine speed, the amount of heated air admitted becomes practically negligible and the greatest volumetric efficiency of the fuel is obtained. As the engine is throttled down, the amount of cold air admitted io reduced by the gradual reduction of the suction through the cold air intake, and the amount of heated air admitted is proportionately increased, thus serving to keep the fuel from recondensing and preventing popping in the carburetter and backfiring in the silencer. The system, in itself, is extraordhaarily simple but the discovery of the principle involved and the attainment of the mechanical simplicity of application have involved many years of labour and research.

Fig. 1 shoWs the top of the carburetter with the parts intuiteid as in Figs. 1 and 2. It also shows the flange foreonnecting up to the induetion pipe of the engine, the spindle and arms of the throttle valve and the adjustable stop for the valve. Fig. 4 shows the mode of connecting the hot air, intake to the jacket of an exhaust manifold, the accessibility of the jet-adjusting needles and plug to petrol duct being apparent. The carburetter is applicable to any make or type of engine, ard it can be adjusted to deal with any fuel —heavy or light. It is being handled in this country by Carburation (Temperature Control), Ltd., with teinnorary offices at 59, Shaftesbury Avenue, London, W.0