Eom Drivers &Mechanics

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light Up Your Lamps At 7.45 on Thursday ; 7.42 on Friday ; 7.40 on Saturday; 7.36 on Monday ; '7.34 on Tuesday ; 7.32 on Wednesday.

Fitting Bushes to Motor-shaft Bearings.

The sender of the following communication has been awarded the 10s. prize this week.

[1660] " S.C." (Glasgow) writes :—" Perhaps the following recommendations regarding the fitting of bushes would be useful to some of your readers ?

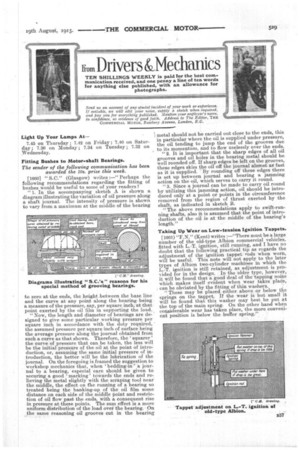

"1. In the accompanying sketch A is shown a diagram illustrating the variation of oil pressure along a shaft journal. The intensity of pressure is shown to vary from a maximum at the middle of the bearing

to zero at the ends, the height .between the base line and the curve at any point along the bearing being a measure of the pressure, say, per square inch;.at that point exerted by the oil film in supporting the load.

"Now, the length and diameter of bearings are designed to give some particular working pressure per square inch in accordance with the duty required, the assumed pressure per square inch of surface being the average pressure along the journal obtained from such a curve as that shown. Therefore, the ' squarer ' the curve of pressure that can be taken, the less will be the initial pressure of the oil at the point of introduction, or, assuming the same initial pressure of introduction, the better will be the lubrication of the journal. On the foregoing is framed the suggestion to workshop mechanics that, when 'bedding-in 'a journal to a bearing, especial "care should be given to securing a good ' marking ' towards the ends and relieving the metal slightly with the scraping tool near the middle, the effect on the running of a bearing so treated being the banking-up of the oil film some distance on each side of the middle point and restriction of oil flow past the ends, with a consequent rise in pressure at these points. The sum effect is a more uniform distribution of the load over the bearing. On the same reasoning oil grooves cut in the bearing ; metal should not be carried out close to the ends, this in particular where the oil is supplied under pressure, the oil tending to jump the end of the grooves due to its momentum, and to flow uselessly over the ends. "2. It is important that the sharp edges of all oil grooves and oil holes in the bearing metal should be well rounded off. If sharp edges be left on the grooves, these edges skim the oil off the journal almust as fast as it is supplied. By rounding off these edges there is set up between journal and bearing a jamming action on the oil, which serves to carry it round. "3. Since a journal can be made to carry oil round by utilizing this jamming action, oil should be introduced only at a point or points in the circumference removed from the region of thrust exerted by the shaft, as indicated in sketch B. "The above recommendations apply to swift-running shafts, also it is assumed that the point of introduction of the oil is at the middle of the bearing's length."

Taking Up Wear on Low-tension Ignition Tappets.

[1661) "F.N." (Kent) writes :—"There must be a large number of the old-type Albion commercial vehicles, fitted with L.-T. ignition, still running, and I have no doubt that the following practical tip as regards the adjustment of the ignition tappet rods when worn, will be useful. This note will not apply to the later types of Albion two-cylinder machines in which the L.-T. ignition is still retained, as adjustment is provided for in the design: In the, older type, however, it will be found that a goad deal of the tapping noise which makes itself evident when wear takes place, . can be obviated by the fitting of thin washers. "These may be placed either above or below the springs on the tappet. If the wear is but small it will be found that this washer may best be put at the top of the main spring. On the other hand when considerable wear has taken place, the more convenient position is below the buffer spring."