Removing and Replacing Albion Brake Shoes.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

When removing the brake shoes of an Albion vehicle, the release springs cannot first he disconnected, but into the hole at the top end of each brake shoe can be inserted a long steel rod, which can be utilized to aet as a lever. By pressing down the • end of this lever the brake shoe will be lifted clear of the fuloriim pin. The brake shoes can then be slipped o•tT the cam quite easily. When replacing the shoes, first set them at rightangles, and then replace the rear shoe in position on the fulcrum pin and actuating cam. The right-hand shoe should then be turned round until its lower end is against the actuating cam. Now insert a similar +,ever to that described above into the hole in the top of the ;shoe as was done for its removal, and ".ever this end of the shoo on to the fulcrum pin. The operation of replacing the shoe•s will be assisted if they are packed up to the right height so that. use of the lever does not force the right-hand shoe out of position.

The Care of Chains.

This hint does not apply to any particular make of vehicle, but to all those which employ chains in their final drive. The, efficiency of this form of -drive depends to a -great extent upon the way in which the chains are treated. A chain which is run dry and -coated with dirt will not only absorb a lot of power, but will have a very short life, and will also reduce the life of the sprockets over which it runs. Many vehicles are provided with chain cases, and whilst these certainly prevent a considerable amount of dirt from reaching the chains, they also hide the chains from aiew, and the drivel...is apt to neglect them because they are out of sight. With exposed chains,. they should be removed at least once a week, soaked thoroughly in paraffin, and then in warmed grease, so that the , melted grease fills :all the crevices between the bushes and the pins. The chains Should be, left in the grease until the latterhas again solidified ; this will prevent the grease from running out. The amount of stretch permissible depends. greatly -upon circumstances. It is difficult to give any specific figures, but wear can soon be gauged by the way in which the chain rides on the tops of the sprocket teeth. The sprockets themselves gradually wear on one side only of the teeth, and it is a good practice to changeover the sprockets when the wear becomes pronounced, thus doubling their life.

Lifting Leyland Cylinders.

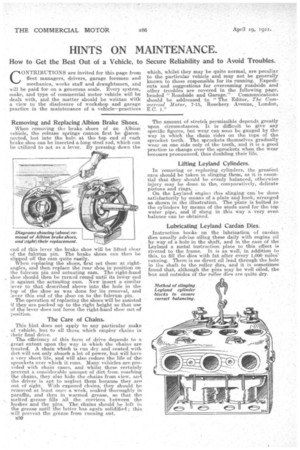

In removing or revlaeing cylinders, the greatest ears should be taken in slinging them, as it is essential that they should be evenly balanced, otherwise injury may be done: to the, comparatively, delicate pistons and rings. , On the Leyland engine this slinging can' be done satisfactorily by means of a plate and hook, arranged as shown in the illustration. The 'plate is bolted to the cylind,ers by means of the studs used for the top water pipe, and if slung in this way a very even balance can be obtained.

Lubricating Leyland Cardan Dies.

Instruction books on the lubrication of eardan dies usually advise oiling these daily with engine oil by way of a hole in the shaft, and in the case of the Leyland a metal instruction plate to this effect is riveted to the frame. It is as well, in addition to this, to fill the dies with fat after every 1,000 miles' running. There is no direct oil lead through the hole in the shaft to the roller dies, 'and it is sometimes found that, although the pins may be well oiled, the box and outsides of the roller dies are quite dry. .