Luxury with a Capital 'L' in land Group' New Cab

Page 128

Page 129

Page 130

Page 131

Page 132

If you've noticed an error in this article please click here to report it so we can fix it.

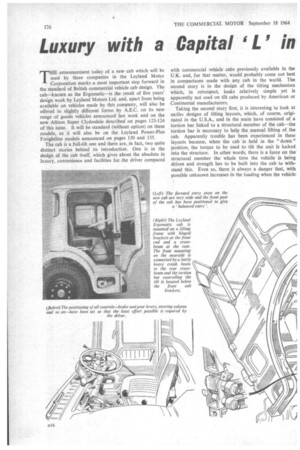

BY A. J. P. WILDING, A.M.I.MECH.E. THE announcement today of a new cab which will be used by three companies in the Leyland Motor Corporation marks a most important step forward in the standard of British commercial vehicle cab design. The cab—known as the Ergomatic—is the result of five years' design work by Leyland Motors Ltd. and, apart from being available on vehicles made by this company, will also be offered in slightly different forms by A.E.C. on its new range of goods vehicles announced last week and on the new Albion Super Clydesdale described on pages 123-124 of this issue. It will be standard (without option) on these models, as it will also be on the Leyland Power-Plus Freightline models announced on pages 130 and 135.

The cab is a full-tilt one and there are, in fact, two quite distinct stories behind its introduction. One is in the design of the cab itself, which gives about the absolute in luxury, convenience and facilities for the driver compared

with commercial vehicle cabs previously available in the U.K. and, for that matter, would probably come out best in comparisons made with any cab in the world. The second story is in the design of the tilting mechanism which, in retrospect, looks relatively simple yet is apparently not used on tilt cabs produced by American or Continental manufacturers.

Taking the second story first, it is interesting to look at earliei designs of tilting layouts, which, of course, originated in the U.S.A., and in the main have consisted of a torsion bar linked to a structural member of the cab—the torsion bar is necessary to help the manual lifting of the cab. Apparently trouble has been experienced in these layouts because, when the cab is held in the " down " position, the torque to be used to tilt the unit is locked into the structure. In other words, there is a force on the structural member the whole time the vehicle is being driven and strength has to be built into the cab to withstand this. Even so, there is always a danger that, with possible unknown increases in the loading when the vehicle goes over bumps and so on, the strengthening will be insufficient; also, there is always a possibility of fatigue failures. This has led in recent times to a tendency in the U.S. to employ powered tilting instead, either by electric or hydraulic means.

Leyland's answet to the problem is, as pointed out earlier, quite straightforward and simple. But similar layouts were not known of when the .design was started and the idea is now the subject of patent application, patent searches to date having failed to reveal that the same idea has been put forward by anyone else. A torsion-barassisted lift is used, but what in effect has been done is to divorce the cab structure from the lifting system. In other words, following the trend in America, an independent lifting means is provided but a torsion bar Is used to give the power instead of electric or hydraulic methods.

Mounted on Lifting Frame The cab itself is mounted on a lifting frame in a similar way to that of conventional cabs. But instead of being on brackets attached rigidly to the chassis frame it is mounted on hinged brackets at the front end and a crossbeam at the rear; there are two mounting points at the front and two at the rear, the front brackets being at the ends of the chassis main members and the spacing at the rear similar. The front mounting on the near side is connected by a fairly heavy cranked beam to the rear cross-beam and below the front brackets is the torsion bar. This is fixed at the right-hand side to the chassis frame and at the other end a short arm is connected by an adjustable link to the cranked beam. The force put into the torsion bar when the cab is lowered is therefore applied through the short arm and cranked beam to the rear cross-bar to give assistance in tilting the cab forward.

By altering the length of the adjustable strut, the amount of assistance can be varied so that the manual effort for tilting can be increased or reduced. The effort can be virtually nil—finger-tip operation—to any required figure. In the fully forward position, a stop on the lower, short arm comes against the cranked beam to halt the lilting, the maximum tilt being 55. In the " down " position, the rear cross-bar is locked on to the chassis at both sides,

the way in which this is done varying between the A.E.C., Leyland and Albion versions.

The operation of the tilt is very simple and the whole cab, with the exception of the driver's floor area, steering column and controls, tilts. To carry out the job all that needs to be done is to unlock the driver's...seat at the rear by using a small lever, tilt it forward over the steering wheel and release the cab-locking mechanism. The cab can then be tilted forward, and in the fully tilted position complete accessibility is given to the near side of the engine—as much as on a bare chassis—and access to the driver's side of the unit is only slightly restricted by the existence of the fixed portion of floor. Sealing of the cab to the floor is accomplished by a large-section, foamrubber-filled, neoprene-covered moulding all round the edge of the floor.

Whilst even comprehensive servicing of the engine can be carried out by tilting the cab, there will sometimes be the need to remove the whole assembly. This also is a very simple job and can be completed in about half an hour. All that is necessary is the unbolting of the four cab mountings and disconnecting snap connectors in the electrical wiring to the flashers and interior lights—the head and side lights are in a fixed panel below the cab— and in the case of the Albion cab; to the electric wipers. On Leyland and A.E.C. versions air-operated wipers are standard, and with these there is a quick-release coupling in the pipework which has to be disconnected. All other wiring is on the fixed portion of the cab with all the fuses and main connections located in a compartment in the plastics surround of the steering column. Because of the layout of wiring and so on it is possible to drive the vehicle when the main cab structure has been removed.

Whilst the basic tilting-control layout is the same for Leyland, Albion and A.E.C. versions, the method of locking varies. With the Albion unit, the locking method was explained in the description of the chassis to which the cab is fitted, but in the case of the A.E.C.S, the cab could not be dealt with at the introduction and the locking is similar to the Leyland, being an automatic catch with an overcentre locking lever and simple-action release.

Although the general design of all three versions is the same—the cab is of all steel with double skinning in places and identical fittings and so on—there are slight changes in external styling between them. The important features of the design are all the results of the decision that the requirements of the driver should be the sole criterion in 1418 the layout of seating, steering, controls and so on, and that the chassis on which it is fitted should be made to suit the result, rather than that the cab should be made suitable for the chassis.

It is fascinating to hear Leyland engineers talk about the factors taken into consideration in determining such things as the size of the door, height of the seat, position of the steering wheel and of the pedals, and of all the other part of the unit. At the start, a comprehensive survey wa! made by Leyland of the requirements for the ideal cab with groups of students touring the country rneasurint drivers as well as cab layouts already in existence. plastics "man" was produced for studies into the bes layout. The result is that drivers from 5-ft. 2-in. te 6-ft. 1-in, tall should find the cab laid out satisfactorily.

Very briefly, the procedure in producing the design wa .that, having decided on a particular maximum size of tyn which would be used on front axles of vehicles to whicl the cab would be fitted, the minimum seat height was fixed taking into account the amount of seat padding though necessary. The maximum tyre size, incidentally, i 11-00-22.

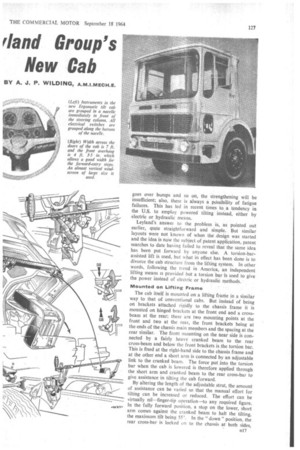

Ergonomic Man In designing cabs—as with other things such as ea seats and furniture—what can be best described as ai average man has been developed. This is called th "90 percentile ergonomic man" and the use of this deter mined the floor height of the cab, the positions of th pedals and the height of the step forward of the fror wheels. The front post of the cab was positioned to giv a balanced entry '—one that allows a man to get into th cab without twisting his body or getting his legs awkward] placed and, of course, without being off balance. The ste is very wide and on the passenger side—where the entr is identical to that on the driver's—because there is n steering column in the way, it is possible to enter the ca without holding on to grab handles, although these at provided.

The location of the steering column and the angle inclination and height of the wheel above the seat ha% been set so that the least effort on the part of the drive is needed to manceuvre the vehicle, and the same consider tions have been applied to the position of the gear chant arid handbrake levers.

Apart from setting the height of the seat, its positie relative to the centre line of the chassis is such that litt novennent is required by the driver to get his head out of he cab through the door window for reversing and so on. his has meant that the seat is closer to the door than on nany current designs, and also that there is more space etween the engine cover and the steering column than is isual.

The location of controls also received considerable attenion, here the main factors being ease of operation (without xcessive reaching) and positioning of the instruments for asy reading.

An almost vertical windscreen was a requirement because f all the factors needing to be taken into account. It is a cry large screen, curved both in the vertical and horizontal lanes. The top edge gives the "90 percentile man" a 12' pward angle of vision (1° more than the most severe !.quirements in countries where a figure is recommended) ad the bottom edge is made as low as practicable to give view as close as possible in front of the vehicle. In the Ater case, the position of the bottom of the screen has ieant that on chassis suitable for the cabs the radiator has ad to be mounted very low down and the cooling fan ansferred to the crankshaft pulley.

One of the biggest features of the cab design is the sating and demisting facilities. In the early days of design work, Smiths were consulted on this aspect, this :ing an important factor in getting an efficient unit and e reverse of the normal procedure where the heater aker is consulted after the cab design has been finalized, id in most cases has an almost impossible task of fitting efficient unit because of lack of space.

In a way, the Leyland cab can be said to be built round e heater, which has the remarkable output of 7.9 kW., 26,000 Btu—about half that of a boiler which would be quired for the central heating of a family house.

A heater of this capacity was decided upon so that even the most adverse conditions the whole of the large windreen would be demisted (or defrosted), even up to the treme top and side edges; and, at the same time, so that equate heating for driver and passenger were also nvided. There are also demisting ducts for the swivelling ndows in both the doors. As with the four below the ndscreen, special controlled outlets have been developed Lich allow air to be directed on to or away from the Lss, or cut off altogether, in the last case so that the full at output can be directed to the other heating outlets. ese controls are actually on the ducts themselves so that rticular ones can be cut off if need be. There is also a tapered valve which can be used to vary accurately the rate of water flow in the system, whilst the air intake in the front of the cab can be closed and the system changed to a recirculatory one if a vehicle blowing out obnoxious fumes is being followed.

The standard of interior trim and finish in the cab is very high and it is surprising the amount of detail that has been given to even the smallest points. For example, the drop windows in the doors are operated by singlemovement levers (as used to be fitted on luxury cars) so that the windows can be lowered quickly if need be; a good-sized, anti-glare visor is fitted which can be swung against the top of the driver's door to cover the top of its window; the passenger is given an arm rest on his door and the top of the engine cover is padded for him to rest his other arm on. There are, in fact, so many points that it would be impossible to list them all here.

A good deal of attention also has been given to mirrors. These are mounted on extensible frames securely bolted to the doors through brackets above and below the windows. There are two mirrors on the driver's side and one on the passenger's; one of the driver's is a rectangular convex for distance, with equal curvature vertically, and horizontally, the other a large, rectangular flat mirror which gives an accurate picture of what is behind the vehicle. On the passenger's side, the mirror is also rectangular and convex, but with different curvatures vertically and horizontally to give a wider-spread view, with a reduced distortion of the height of vehicles behind.

The cab for all three I.eyland Corporation companies is being made by Sankeys in a plant newly built for the purpose. Capacity of this factory initially is 506 cabs a week and included in the facilities is a £140,000 dipping plant where the cabs will be completely immersed in primer paint. Painting will be carried out using electrostatic spraying, which ensures complete coverage and is particularly valuable in giving an adequate coating to corners.

The width across the doors of the new cab is 7 ft., this allowing the minimum dimension over the wings to be 7 ft. 2-5 in., which is a requirement in some overseas countries. There is provision, of course, for the measurement over the wings to be 8 ft. 2.5 in., this depending on the axle and tyres specified. At present the cab is being made in only one size, with a depth from the front to back of 5 ft. It is, however, planned to produce models 4 ft. deep and eventually a 6-ft.-deep, sleeper-cab version.

In standard form, the windscreen will be toughened glass

(zone toughened), but for overseas, tinted laminated screens will be available, these reducing the visibility by 15 per cent and excluding all ultra-violet and reducing infra-red rays. Windscreens with shading at the top will also be offered.

Insulation of the new cab, both against heat, and more particularly against noise, is very comprehensive. The engine cover carries Stillite insulation all round its interior surfaces, held in place by perforated light-alloy foil and perforated sheet steel, and on the underside of the roof Vynair sheet bonded to glass wool is used. Because a lot of noise can get between adjoining metal parts if the seal between is only a thin rubber moulding, the seals at points such as the removable engine cover are made as wide as possible, and care has been taken that the insulation value is not reduced when the rubber settles. At the doors, double sealing is used and the engine cowl is covered in plastics material, which adds to the insulation of noise at this point.

As well as the optional windscreens mentioned, the centre glass panel at the back of the cab can be supplied with a sliding portion and various options for the roof are offered, including a heat shield and a hinged opening flap.

To fit the tilt cab, a particular contour at the front end of the ctu,ssis frame is required, and with the cab's intro duction the design of Leyland and Albion, as well a A.E.C. chassis to which it is to be fitted, has beei rationalized There has been no alteration to Scammel chassis, but this concern in the Leyland Group may corn into line later. This rationalization includes a comma position of front axle and design of chassis-fram main-members.

I have not driven in the cab but it is sufficient t sit in it to realize the quality of fittings, the remarkabl well-laid-out controls, the perfectly placed gear change handbrake and so on, and the very comfortably positione steering wheel. Getting into and out of the cab is cor siderably easier than on any other I have ever come acro5. from a U.K. manufacturer, and although external appeal ance may be strange to British eyes in the beginning, think it is a style which will come to be acceptable.

Leyland well deserves praise for the design, but on on point I would criticize—that it was felt necessary to go t the 'Italian designer Michelotti for the external stylini Surely there are British stylists who could have done a equally good job? But then this may not be the case, fc reports suggest that one of Michelotti's great skills is i producing a good appearance with adequate account take of engineering principles, in strengthening members an other things. In other words, as with the new cab, n4 just a pretty face.