Face-lift r Firm Favourite

Page 84

Page 85

Page 86

Page 87

If you've noticed an error in this article please click here to report it so we can fix it.

By Anthony Ellis

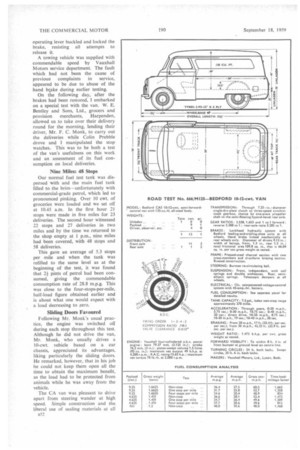

SINCE its introduction in 1952, the Bedford CA 10-12-cwt. chassis and its 15-cwt. variation have sold at the rate of about 150 a day—a figure near the production capacity of the line which was set up originally at Luton to construct them.

Its semi-forward-control layout is partly responsible for this success. The driver can easily reach his seat from the near side, whilst he has free access to the load from the front—a valuable and time-saving feature on multi-stop deliveries.

Disadvantages of the design are the need for a short (161-in.) bonnet, which reduces body capacity for the given overall length, and the difficulty of providing even weight distribution over the front and rear axles. For many operators, these snags are outweighed by the provision of sliding cab doors without the need for a narrow front track and the benefits of really easy access.

The first major alteration in the chassis specification of the CA van took place in 1957, when the new engine and three-speed synchromesh gearbox developed for the Vauxhall Victor car were substituted for the similar, but lower-powered, engine and part-synchromesh gearbox used previously. At the same time, recirculating-ball steering superseded the screwand-peg type.

Early this year changes were made in the body styling with a revised front grille design and a one-piece curved windscreen replacing the two flat panels used before. The latter modification was an answer to criticism of the restricted vision caused by the thick pillars of the two-piece screen. Wheel sizes were reduced from 16 in. to 15 in. and tyre equipment became 5.90-15-in. (6-ply) on the 10-12-cwt. and 6.40-15-in. (6-ply) on the 15-cwt.

a50 Since these alterations were made another change in body appearance has occurred with the elimination of spats for the rear wheels. In the interests of cheaper production the body side panels are now one-piece pressings cut away at the rear wheels.

Flashing direction indicators, which had previously been an option at additional cost, were incorporated as a standard fitting, as were two-speed windscreen wipers.

Loaded for my test with 9f cwt. of sandbags, the standard van provided, which weighed exactly 1 ton unladen, scaled 1 ton 131 cwt. with myself and Colin Prebble, of Vauxhall Motors, aboard, this being just 24 lb. over the recommended gross weight. The rear axle was carrying 1 ton 11 cwt. of the evenly spread load, with only 111 cwt. on the front wheels.

The light loading on the front axle is one of the difficulties with the semi

forward-control layout. Although it gives light steering, it overloads the rear tyres and gives rise to some steering wander above 60 m.p.h.

Two cylinder heads are available, giving compression ratios of 6.8 to-I and 7.8 to 1 for operation on commercial-grade and premium-grade

petrols respectively. The test van had the high-compression head. Fuel used for the consumption runs, which took place over our usual six-mile test course on the ' A6 road between Barton and Clop Hill, was, therefore, premium grade.

Just over 30 m.p.h. was maintained wherever possible on the non-stop runs, whilst the vehicle was halted with the engine idling for 15 seconds at each stop on all other runs.

When compared with the figures obtained on the first road test of the original CA van, running at almost the same weight (The Commercial Jr, July 4. 1952) the results of ; tests were rather surprising. ough the first test was conducted a different 18-mile course at a m. average speed with a lower;red engine, the original van gave 0.4 m.p.g. less on non-stop ing fully laden and 2.6 m.p.g. less ,ur stops per mile. Although the mum speed of the early CA was r than that of the present model, eration rates were almost ical on both road tests.

is is probably because of the use wer gearbox and rear-axle ratios le present CA, with smaller tyres ive much-reduced overall gear This has been done to cater he higher maximum revolutions le current engine (4.200 r.p.m. 7.8 to 1 compression), compaed 4,000 r.p.m. with the earlier e, and to give the van except gradient ability.

1-climbing of a high order was nstrated on Bison Hill, near snade. The *-mile ascent with ierage gradient, of 1 in l04 was in 2 minutes 14 seconds with gear in use for only 12 seconds. tromesh for the lowest ratio downward changes into it tionally swift and unembarrassmphasizing again the desirability is provision on a hard-worked .speed gearbox.

Ambient temperature was 62° F. and the coolant temperature at the bottom of the hill was 180° F. After the fast ascent, the radiator temperature had dropped to 179° F., whicn must have been caused by the high engine speed and consequent efficient fan cooling.

To test for brake fade, the van was coasted down the hill with the speed restricted to 20 m.p.h. by , the foot brake. As the gradient decreased towards the bottom, top gear was engaged and the vehicle driven at full throttle against the -brake at the same speed. The descent took 2 minutes 45 seconds and a "crash '—stop at the bottom produced the satisfactory Tapley reading of 80 per cent., which compares favourably with the figure of 91.5 per cent, obtained later in the day from 20 m.p.h. with cool brake drums. Although the brakes were hot, pedal travel had not increased appreciably.

A restart was then made on the 1-in-6 section, on which the pull-up hand brake held the vehicle easily. On White Hill, near Bovingdon, which has a maximum incline of about 1 in 41, easy restarts were also made at the normal weight and with an extra 3 cwt. of sandbags to bring the vehicle up to the gross weight of the 15-cwt. model.

The hand brake was capable of holding the vehicle on this gradient. The tests suggested that the van would be able to get away satisfactorily on gradients steeper than 1 in 4. A level stretch of the A6 road just outside Harpenden was used for the acceleration runs. Fast gear-changing for the through-the-gears tests was aided by the excellent synchromesh mechanism of the gearbox; changes could be made almost as fast as one could move the steering-column lever.

Moreover, the geometry of the lever-to-gearbox linkage makes for extremely smooth action—so smooth, in fact, that one might easily assume that hydraulic actuation was employed. This is the best steering-column gear-change I have ever encountered and shows that the problems arising from this form of control can be overcome.

Maximum speeds in the gears were 24 m.p.h. in first, 40 m.p.h. in second and more than 65 m.p.h. in top. Acceleration in top gear was completely smooth and vibration-free from under 10 m.p.h. up to the maximum speed of the vehicle.

A very rough, freshly laid granitechipping surface was found for the brake tests and good stopping distances were obtained. From both 20'rn.p.h. and 30 m.p.h. all the wheels marked the road surface, which, in its turn, removed much rubber from the finely cut treads. Braking was even. requiring no excessive steering correction for the vehicle to pull up in a straight line.

Disaster occurred when the hand brake was tested. Although powerful retardation resulted, giving a reading on the Tapley meter of 43 per cent., my vigorous application of the sensibly situated lever proved to be too much for the actuating mechanism on the near-side rear brake drum. The operating lever buckled and locked the brake, resisting all attempts to release it.

A towing vehicle was supplied with commendable speed by Vauxhall Motors service department. The fault which had not been the cause of previous complaints in service, appeared to be due to abuse of the hand bake during earlier testing.

On the following day, after the brakes had been restored, I embarked on a special test with the van. W. E. Bentley and Sons, Ltd., grocers and provision merchants, Harpenden, allowed us to take over their delivery round for the morning, lending their driver, Mr. F. C. Monk, to carry out the deliveries while Colin Prebble drove and I manipulated the stop watches. This was to be both a test of the van's usefulness on this work and art assessment of its fuel consumption on local deliveries.

Nine Miles: 48 Stops

Our normal fuel test tank was dispensed with and the main fuel tank filled to the brim-unfortunately with commercial-grade petrol, which led to pronounced pinking. Over 10 cwt. of groceries were loaded and we set off at 10.45 a.m. In the first hour 21 stops were made in five miles for 23 deliveries. The second hour witnessed 22 stops and 27 deliveries in two miles and by the time we returned to the shop empty at 1 p.m., nine miles had been covered, with 48 stops and 58 deliveries.

This gave an average of 5.3 stops per mile and when the tank was refilled to the same level as at the beginning of the test, it was found that 21pints of petrol had been consumed, giving the commendable consumption rate of 28.8 m.p.g. This was close to the four-stops-per-mile, half-load figure obtained earlier and is about what one would expect with a load decreasing to zero.

Sliding Doors Favoured

Following Mr. Monk's usual practice, the engine was switched off during each stop throughout this test. Although he did not drive the van, Mr. Monk, who usually drives a 10-cwt. vehicle based on a car chassis, appreciated its advantages. liking particularly the sliding doors. He remarked, however, that in his job he could not keep them open all the time to obtain the maximum benefit, as the load had to be protected from animals while he was away from the vehicle.

The CA van was pleasant to drive apart from steering wander at high speed. Simple construction and the liberal use of sealing materials at all

a57

its make the body exceptionally et and no noticeable panel drumtg occurred at any time during the ,ome knack was required to enable nan over 6 ft. tall to get into the fing seat easily, because of the posit of the off-side wheel-arch. Once has done so, the driving attitude is d, with vision much improved by one-piece windscreen, although short bonnet still cannot be seen Ti the driver's seat. However, one n becomes accustomed to this een forward projection.

'he standard passenger seat, which ; fitted to the test vehicle, is ated aft of the near-side sliding or, so as not to impede access to driving seat from this side.

/mined from the latest CA van is full-width shelf above the wind!en. The only provision made for ing personal items is a rather npery open-topped box on top of front near-side wheel-arch, out of of the driver. A commendable extra fitted to the vehicle was a Bedford truck radio. This unit, which costs only £17 19s. 7d., performed extremely well, giving clear reception under all conditions. Its mounting place, on top of the off-side front wheel-arch, appeared, however, to make it vulnerable to accidental damage.

1 carried out a number of maintenance tasks. Bodywork changes have done little to improve the accessibility of the engine for routine servicing and the fitter who works on it still has to have some of the agility of a contortionist.

Nevertheless, I, who am not of eellike proportions, managed to remove the sparking plugs, working from inside the cab, in 10 minutes, 37 seconds and replaced them in 3 minutes 24 seconds. The radiator water level was checked through the small hinged trap in the bonnet in 10 seconds and the oil level, from the cab, in 30 seconds.

The fuel pre-filter was removed, cleaned and replaced in 54 seconds. Having removed the top of the bonnet which is secured by four Dzus Fasteners, in 32 seconds, I was able to check the contact-breaker gap in 1 minute 50 seconds, turning the engine over myself. The front panel took 52 seconds to replace through springing of the surrounding metal.

Working underneath the van, the gearbox and rear-axle oil levels took I minute 40 sceonds and I minute 32 seconds respectively to inspect.

The screw jack provided in the tool kit is too high to go beneath the differential pot. Thus it is necessary to jack up each rear wheel separately and a similar procedure is required for the front wheels, because of their independent suspension. The brakes on each wheel took 3 minutes to adjust.

The CA 10-12-cwt. van as tested costs £445 without radio and passenger seat and the price of its 15-cwt. variation with heavier rear springs and 6.40-16-in. (6-ply} tyres is £452 Is,