MAKING BEST USE OF THE FORD.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport which will Appeal to the Owner, Driver and Repairer.

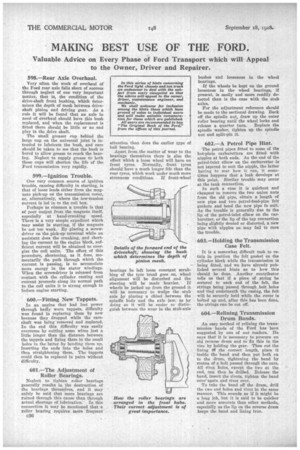

598.—Rear Axle Overhaul.

Very often the work of overhaul of the Ford rear axle falls short of success through neglect of one very important matter, that is, the condition of the drive-shaft front bushing, which determines the depth of mesh between driveshaft pinion and driving gear. As a rule it will be found that an . axle in need of overhaul should have this bush replaced, and when the replacement is fitted there should be little or no end play in the drive shaft.

The small greaser cup behind the large cup on the universal joint is intended to lubricate the bush, and care should be taken to see that the bush is bored to allow grease to reach the bearing. Neglect to supply grease to both these cups will shorten the life of the Ford transmission very rapidly.

599.—Ignition Trouble.

(Me very common source of ignition trouble, causing difficulty in starting, is that of loose leads either from the magneto pick-tip on the transmission cover, or, alternatively, where the low-tension current is led in to the coil box.

Perhaps as common a trouble is that of poor output from the magneto itself, especially at hand-cranking speed. There is a very simple expedient which may assist in starting, if the magnets be not too weak. By placing a screwdriver on the pick-up terminal while an assistant does the cranking, and shorting the current to the engine block, sufficient current will be obtained to energize the coil units. The effect of this procedure, shortening, as it does, momentarily the path through which the current is passing, is to accumulate more energy in the stator windings. When the screwdriver is released from contact with the cylinder casting and current proceeds along its normal path to the coil units it is strong enough to induce engine starting.

600.—Fitting New Tappets.

In an engine that had lost power through badly worn tappets, difficulty was found in replacing them by new because they dropped while the camshaft was being removed and replaced. In the end this difficulty was easily overcome by cutting some wires just a little longer than the distance between the tappets and fixing them in the small holes in tile latter by bending them up, Inserting the ends into the holes and thee straightening them. The tappets could then be replaced in pairs without difficulty.

601.—The Adjustment of Roller Bearings.

Neglect to tighten roller bearings generally results in the destruction of the bearings themselves, and it may safely be said that more bearings are ruined through this cause than through actual shortage of lubrication. In this connection it may be mentioned that -a roller bearing requires more 'frequent attention than does the earlier type of ball bearing.

Apart from.the matter of wear to the bearings themselves there is also the effect which a loose wheel will have on front tyres. Normally, front tyres should have a much longer life than the rear tyres, which work under much more strenuous conditions. If front-wheel bearings be left loose constant scrubbing of the tyre tread goes on, wheel alignment will be disturbed and the steering will be made heavier. If wheels be jacked up from the ground it will be necessary to wedge the stub axle by placing a chisel between the spindle body and the axle jaw, as by doing so it will be easier to distinguish between the wear in the stub-axle bushes and looseness in the wheel bearings.

If the wheels be kept on the ground looseness in the wheel bearings, if present, is easily and more readily detected than is the case with the stub axles.

For the adjustment reference should be made to the sectional drawing. Back off the spindle nut, draw up the outer roller bearing until the wheel locks and release a quarter turn. Replace the spindle washer, tighten up the spindle nut and split-pin it.

602.—A Petrol Pipe Hint.

The petrol pipes fitted to some of tub hot-plate carburetters are fitted with nipples at both ends. As the end of the petrol-inlet elbow on the carburetter is not tapered to suit the nipple, the latter having to seat how it can, it sometimes happens that a leak develops at this point. Similar trouble may occur at the tank connection.

In such a ease it is quickest and cheapest to remove the two union nuts from the old pipe, obtain a length of new pipe and two petrol-feed-pipe felt gaskets and bend the new pipe to suit. As the trouble is generally due to the lip of the petrol-inlet elbow on the carburetter, or the lip of the tap connection being slightly dented or distorted, a new pipe with nipples on may fail to cure the trouble.

603.—Holding the Transmission Case Felt.

It is a somewhat difficult task to retain in position the felt gasket on the cylinder block while the transmission is being fitted, and we have already published several hints as to how this should be done. Another contributor tells us that if a piece of string be secured to each end of the felt, the strings being passed through bolt holes and tied underneath the easing, the felt will be securely held while the cover is bolted up and, after this has been done, the strings can be cut off.

604.—Relining Transmission Drum Bands.

An easy method of relining the transmission bands of the Ford has been suggested by one of our readers. He says that it is necessary to procure an old reverse drum and to fix this in the vice by holding the gear. Then cut the lining tfl the correct length', place it inside the band and then put both en to the drum, tightening the band by means of a bolt passed through the ears. All rivet holes, except the two at the end, can then be drilled. Release the band, insert the rivets, tighten the band once' again and rivet over.

To take the band off the drum, drill the two end holes and rivet in the same manner. This sounds as if it might be a long job, but it is said to he quicker and more accurate than other methods, especially as the lip on the reverse drum keeps the band and lining true.