DRILLING AND TAPi 3 ING.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Some Valuable Advice Tendered by Our Driver and Mechanic Readers.

WHILE WE are just a little doubtful as to the practicability of the

tool which is described by " of Stratford-on-Avon, we are nevertheless awarding him the 15s, prize this week for his ingenuity in solving what has always been more or less a problem to the ordinary mechanic, unequipped with any special tools.

Cases frequently arise in which a new cover is required for a liandhoIe, or a new patch for a hole. The main casting, or whatever it may be, is already prepared for the reception of the cover; most likely it has had such a cover before. In the maker's shops, the cover would have been drilled first—that is, supposing that the holes in both have not been drilled to jig. The new cover, Patch, or suchlike component, has no holes in it, but must be drilled most carefully so that the holes in it will register accurately with those in the existing piece. Unfortunately, as often happens, it is impossible to mark Off the new cover from the old part, and access cannot be had to the other side of the main piece to mark the cover off from that.. A template is not practicable. What must be done?

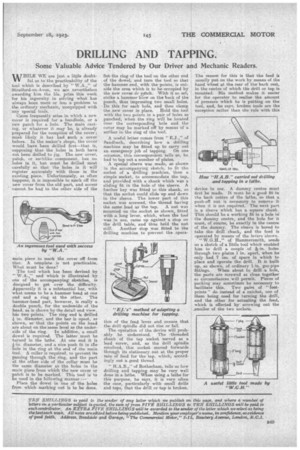

The tool which has been devised by " W.A.," and which is illustrated by one of the accompanying sketches, is designed to get over the difficulty. Apparently it is a substantial bar, with what seems to he a hammer head at one end and a ring at the other. The hammer-head part, however, is really a double punch, for the underside of the head, as is shown by the detail end view, lati.s two points. The ring end is drilled in. diameter, and the bar is upset, as shown, so that the points en the head are about on the Same level as the under side of the ring. In addition, a small dowel is required. The latter must be turned in the lathe. At one end it is On. diameter, and a nice posh fit in the hole in the ring at the end of the main tool. A collar is required, to prevent its passing through the ring, and the part at the other side of the collar meet be the same diameter is the holes in the main piece from which the new cover or patch is to he marked. This tool is to be used in the following manner :— Place the dowel in one of the holes from which marking out is to be done.

Set the ring of the tool on the other end of the dowel, and turn the tool so that the hammer end, with the points, is outside the area which is to be occupied by the new cover Or patch. With it so set, strike a, hammer blow on the back of the punch, thus impressing two small holes. Do this for each hole, and then clamp the new cover in place. Hold the tool with the two poiets in a pair of holes as punched, when the ring will be located over the corresponding hole and the cover may be marked off by means of a scriber in the ring of the too!.

useful letter comes from " E.J.," of Sandbaeh, describing how a drilling machine may be fitted up to carry out an emergency job of tapping. On one occasion, this correspondent tells us, he had to tap out a number of plates.

A special sleeve was made, aa shown in the accompanying sketch, to fit the socket of a drilling machine, then a simple socket, to accommodate the tap, and provided with a shank which was a sliding fit in the hole of the sleeve. A feather key was fitted to this shank, so that the socket could slide up and down in the sleeve. The lower part of this socket was screwed, the thread having the same lead as the tap. A nut was mounted on the socket as shown, fitted with a long lever, which, when the tool was in use, came up .againet, a stop on the drill table, and thus held the nut

still. Another stop was fitted to the drilling machine to prevent the opera tion of the feed lever and ensure that the drill spindle did not rise or fall. .

'rho operation of the device will 'probably be understood, The 'threaded shank of the tap socket served as a lead screw, and, as the drill spindle revolved, this socket moved forwards through its stationary nut at the proper rate of feed for the tap, which, accordingly cut a.good thread.

" H.A.B.," of Rotherham, tells us how drilling and tapping may be very well done in a lathe. When using a lathe for this purpose, he says, it is very often the case, particularly with small drills and taps, that the drill or tap is broken. The reason for this is that the feed is usually put on the work by means of the hand wheel at the rear of the back rest, in the centre of which the drill or tap is mounted. His method makes it. easier for the operator to realize the amount of pressure which he is putting on the tool, and, he says, broken tools are the exception rather than the rule with this

device in use. A dummy centre, mustfirst be made. It must be a good fit in the back centre of the lathe, so that a pesh-off nut is necessary to remove it when it is not, required. The next part is a sleeve which has a square shank. This should be a working fit in a hole in the dummy centre, and the hole for it must, of course, be exactly in the centre of the dummy. The sleeve is bored to take the drill chuck, and the feed is operated by means of the levers shown. " W.G.H.," of Hammersmith, sends us a sketch of a little tool which enabled him to drill is couple of pe-in. holes through two plates 1 in. apart, When he only had 7 ins, of space in which to place and operate the drill. It is built up, as shown, of ordinary I-in. gas-pipe

fittings. When about to drill-a hole, the parts are screwed as close together as circumstances will permit. Pieces of packing may sometimes be necessary to facilitate this. Two pairs of " footprints " do instead of a ratchet, one of them being used for turning the drill, and the other for actuating the teed, which is effected by screwing out the _smaller of the two sockets.