HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

Flow to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble. ................

426:—Extracting a Stubborn Valve Cap.

Some little time ago we included amongst our Hints on Maintenance one referring to a special spanner for the removal of stubborn valve caps. The great difficulty with this spanner is that it can only be used for valve caps which are tapped, but in most cases only those for the inlet valve are finished in this manner. This means that another spanner is necessary for the four caps over the exhaust valves.

A reader of this journal has, therefore, sent us particulars of another spanner, which also is for use with castellated valve . caps,. but can be applied whether these caps be tapped pt. not.

The tool consists of a circular bar of steel, about I in. in diameter and 2 ft. in length. One end of this is "jumped up" to form a key exactly to fit the castellations of the cap.

If a valve cap cannot be unscrewed using this spanner alone; the tool can be extended by the use of a 4-ft. length of iron piping of such a size that it just fits the round end of the spanner. This will give. a 5-ft lever, and it is most unlikely that a valve cap can be found to resist the force that can then be applied.

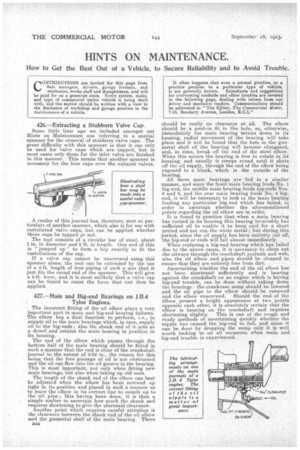

427.—Main and Big-end Bearings on • Tylor Engines.

The incorrect fitting of the oil elbow plays a very important part in main and big-end bearing failures.

The elbow has a dual function to perform, i.e., to supply oil to the main bearings which, in turn, supply

oil to the big-ends ; also the shank end of it acts as a dowel and retains the main bearing in position in Its housing.

The end of the elbow which passes through the bottom half of the main bearing should be fitted in such a manner that the end is clear of the crankshaft journal to the extent of 3/82 in., the reason for this being that the free passage of oil is not obstructed and the oil can flow into the oil groove in the bearing. This is most important, not only when fitting new main bearings, but also when taking up old ones.

The length of the shank end of the elbow can best be adjusted when the elbow has been screwed up

tight in its position and placed in such a manner as to leave the elbow in its correct line to couple up to the oil pipe ; this having been done, it is then a simple matter to-ascertain how•much the shank end requires shortening to give the aforesaid clearance. Another point whieh requires careful attention is the clearance between the shank end of the oil elbow and the ‘gunmetal shell of the main bearing. There

E44

— ... should be really no clearance at all. The elbow should be a push-in fit in the hole, as, otherwise, immediately the main bearing Settles down in its housing, radial movement of the bearing will take place and it will be found that the hole m the gunmetal shell of the bearing -will become elongated, 'and, in time, break off the end of the steel elbow. When this occurs the bearing is free to rotate in its housing, and usually it creeps round until it shuts off the oil supply, through the end of the elbow being exposed to a blank, which is the outside of the bearing. All three main bearings are fed in a similar manner, and since the front main bearing feeds No. 1 big-end, the middle main bearing feeds big-ends Nos. 2 and 3, and the rear main bearing feeds No. 4 big end, it will be necessary to look to the main bearing feeding any particular big-end which has failed, in order to ascertain whether the aforementioned points regarding the oil elbow are in order.

It is found in practice that when a main bearing has turned in its housing this bearing invarialloly has sufficient oil to enable it to keep cool for a short period and not run the white metal ; but during this period, since the oil supply has been entirely cut off, 'the big-end or ends will fail almost immediately.

When replacing a big-end bearing which has failed due to the above cause, it is necessary to clean out the oilways through the crankshaft journals and web, also the oil elbow and pipes should be cleaned to ensure that they are entirely free from dirt.

Ascertaining whether the end of the oil elbow has not been shortened sufficiently and is bearing . against the crankshaft on an engine which is having big-end trouble, can be done without taking down the bearings : the crankcase sump should be lowered and the off pipe to the elbow should be removed and the elbow unscrewed. Should the end of the elbow present a bright appearance at two points opposite each other, it is absolutely certain that the elbow is bearing on the crankshaft and requires shortening slightly. This is one of the rough and ready methods of ascertaining quickly whether the nipple has caused the big-end to fail, and since it can be done by dropping the sump only it is well worth looking to on all occasions when main and big-end trouble is experienced.