From Drivers &Mechanics

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light•Up Your Lamps At

7.8 on Thurs. ; 7.6 on Fri. ; 7.4 on Sat. ; 6.59 on Mon. ; 6.57 on Tues. ; 6.54 on Wed.

A Lathe Attachment for Turning Taper Work.

The sender of the following communication has been awarded the Ws. prize this week.

[1326] " G.T." (Hyde, I.O.W.) writes :—" I send you a sketch and particulars of what I have found to be a very useful attachment to be fitted to the tailstock end of a lathe for the purpose of turning taper work, etc.

"To make the rig I proceed as follows. Turn down a piece of mild-steel about 4 in. diameter to the shape shown, and with a taper to suit the lathe. For the centre-piece which takes the work, a piece of toolsteel should be turned to a taper of about 60 degrees included angle, the base is machined rectangular in shape, as shown in the right-hand sketch, so that it can be tapped out with a fine thread ; about 26 per inch I find satisfactory. Care should be taken to get a true cone, and, after machining, it is case-hardened. "Two pieces of mild-steel plate are then bevelled transversely so that the bevel coincides with the lathecentre, when in position, they form a tapered groove to accommodate the hardened cone-piece. The lower plate should extend to the lathe-bed and fit so that it can slide in the bed up to the work. At each end of the groove above referred to is fitted a small plate, which has been tapped out 26 threads per inch. A set-screw is then made sufficiently long enough to take locknuts over one plate, and also allow for adjustment. The bevelled plates are now screwed to the centre disc so that, when fitted securely in position, the small cone is held in a good sliding fit in the 'V' groove. It will be seen that, on turning the set-screw, very fine adjustments can be made, moreover, should a piece of taper-work in hand have to be lifted for more urgent work, the attachments Jnay be taken off the lathe without interfering with the taper setting."

D4

Paraffin Tanks that will not Creep.

[1327] " Designer " (London) writes :—" Now that the use of paraffin is more likely to become general, owing to certain recent developments which overcome that great objection to its use, viz., the necessity for starting on petrol, it may be as well to try and overcome some of the other objections that are often raised when the use of paraffin is considered. The following suggestion may, therefore, be useful. " One of the greatest objections to paraffin is its habit of creeping. In commercial vehicles, in which are often carried food and other delicate articles, which are rendered valueless if contaminated, it becomes a matter of the greatest importance that tanks should be so constructed that creeping is practically impossible. Having had exceptional opportunities of observing the behaviour of paraffin in various forms of tanks, I find that it is quite possible to construct a tank which will not allow paraffin to creep.

"In an ordinary tank, with the filler on the top, creeping is very noticeable, no matter how carefully the tank be filled so that none of the paraffin is left on the top, and no matter how well the cap be tightened down, creeping will soon take place. It is almost impossible to tell how it happens. but the fact remains that, after a time, the top and even the sides will show traces of paraffin.

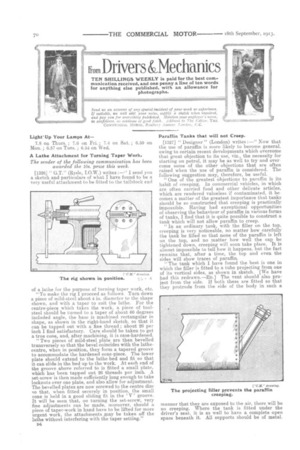

"The tank which I have found the best is one in which the filler is fitted to a tube projecting from one of its vertical sides, as shown in sketch. [We have had this redrawn.—ED.] The vent should also project from the side. If both these are fitted so that they protrude from the side of the body in such a manner that they are exposed to the air, there will be no creeping. Where the tank is fitted under the driver's seat, it is as well to have a complete open space beneath it. All supports should be of metal. A Substantial Form of Road-wheellRepair. 2`.1.

[1328] "A.J.P." (Penalt) writes :—" Some time back the front wheels of the wagon I was driving got a bit shaky. They are built up of wood, and the defect lay with the spokes, which worked very loose around the hubs and in the felloes. The wagon could not be spared to have the matter put right, and as time went on the trouble gradually increased until the wheels were unsafe. I decided to effect a repair myself, and, upon thinking the matter out, set to work and made quite a satisfactory job of it. I send you a sketch [We have had this re-drawn.--FD.], which I think will show how the repair was carried out.

"First of all I made some thin wedges of oak and drove them in between the spokes and the hub from each side of the wheel, trimming them lip and making the hubs quite secure. The next thing to do was to .strengthen up the spokes ; for this purpose I ohtamed some good oak blocks and cut them to the shape of the space between the spokes and drove them in, first wrapping a layer of sacking around each block for the purpose of ensuring a good fit. An iron ring was next screwed to each side of the wheels ;Intl completed what proved to be a very sound job'.

A Letter from the Driver of a Mann Stearn Wagon.

[1329] " IT.B." (Oxon.) writes : --" Having read in your D. and M.' pages letters from various drivers, about both steam and petrol-driven vehicles, stating their running experiences, I send you my own history in this respect, thinking perhaps it may be of interest.

"For upwards of 12 years I have regularly driven Mann steam-wagons, and find they always work admirably. My present employer has two machines of this make in use, both 5-tonners, one being a threespeed overtype machine, and the other an undertype. The latter vehicle has been running for more than three years, and the overtype for just over 12 months ; some of our journeys range from 50 to 60 miles, and we accomplish the distance comfortably in a day. "1 have travelled on all classes of roads and have climbed some of the steepest routes in the Midlands, and up to the time of writing I can say I have had but one breakdown in the whole of my running career. I consider Mann steam-wagons always give excellent results, and my further experience is that repairs to them are especially few in number."

A Reviver for Coloured Leather Upholstery and a Leather Dressing for Slipping Belts.

[1330] " (Ha,rringa,y) writes : -" I frequently come across some very' useful hints for the workshop in your '0. and M.' pages, so send you two recipes which also may be useful for publication, having tried both myself and found them to give every satisfaction. "For making coloured-leather reviver, obtain half a pint of spirit varnish, known to the oilman as white hard varnish' ; to this add two gills of methylated spirits. Thoroughly mix and keep in a bottle well corked, otherwise the ingredients become thick and useless. The mixture should be thinly applied. " A good belt dressing consists of the following ingredients : —To a lb. of Stockholm tar add two ounces powdered resin, to this pour one dram of neatsfoot oil. Slowly heat in a jar until the parts can be thoroughly mixed. When cool the dressing is ready for use. I find that when it is applied to the slackest of belts a lasting grip will be the result. The neatsfoot oil is also a good belt preservative, keeping the leather from corroding and perishing."

Lectures to Drivers.

As announced in our last issue, the C.M.U.A. has organized a series of lectures to drivers of petrol and steam-driven vehicles who are in the employ of members of the Association. .A lecture will be given on alternate Wednesdays at the It.A.C., Pall Mall, S.W., during the autumn and winter. The first of the series will be given on Wednesday, 8th October. Drivers must register with the secretary of the C.M.I.T.A., 89, Pall Mall, S.W., before this date ; the registration fee for each series—petrol and steam, and comprising four lectures, will be Is. A syllabus giving an outline of each lecture may be had on application to the secretary. The lecturer will be Mr. Geo. W. Watson, the Association's inspecting engineer.

Cramps Made with the Aid of a Blowlamp.

[1331] " A.Y." (Walthamstow) writes :—" One of the handiest tools a driver or mechanic can have in his kit is a cramp, and if he be still more fortunate he may have a selection of various sizes at his disposal. As a rule, however, the supply of these in a tool kit is limited,, as in the ordinary way a fairly heavy smithing job is entailed in the forging of the body of the cramp. I send you a sketch We have had this redrawn.—Eni of a cramp I made recently which is not only neat and effective, but was made by use of the lathe and an ordinary blow-lamp, thus doing away with any smithing work. I have made one or two of different sizes, but as an example of a very handy size, the following dimensions will make a cramp which will take work up to 34 ins, wide. " Procure a piece of inch bright bar about 101 ins. long, centre it in a lathe and turn to shape shown, the centre portion being turned # in. diameter down to 4 in, diameter inside the head and foot. The head is left full diameter for about 1 in. in length, and the foot # in. A # in. Whit, tapping hole should be then drilled through the diameter of the centre of the head. Now cut a piece of wire 101 ins, long

and bend it. to the required shape of the cramp, place this along the bar and with a centre-punch mark where the bends should come. Heat with the blow-lamp and then bend at the centre-punch marks. To get the head and foot in line insert a pointed # in. rod through the hole and locate it in the lathe-centre mark in the foot.