A NEW SCAMMELL 40-TONNER

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

A Full and Exclusive Account of a Remark able Type of Articulated Machine for 40-ton Pay-loads, Which Will Climb a Gradient of One in Eight

FTER many years of experi ence ence of the trying problems

of haulage by road of extremely heavy and cumbersome loads, Scammell Lorries, Ltd., the London office of which is at High Holborn House, London, W.C.1, has earned a position of pre-eminence, and a reputation that are known the world over. Apart from four-wheelers for loads under 10 tons and rigid _sixwheelers for cross-country and overseas duty, the company has produced large numbers of articulated machines ranging from 8-ton six-wheelers to the famous and unique 14-wheeler which for the past 12 months has been engaged in transporting loads up to 100 tons.

'Some extremely interesting large-capacity articulated vehicles are being produced at the Watford works of Sca.mmell Lorries, Ltd. Recent deliveries of these new machines have a capacity of not less than 40 tons and are intended for the conveyance of heavy machinery. 'They have eight road wheels and arrangement is made for the detachment of the four trailer wheels, so as to convert the rear end of the carrier unit into a ramp for loading purposes. For such difficult loads. as this type of vehicle is built to carry,, an ingenious arrangement of this kind is extremely valuable. One 40-ton dropframe Machinery transporter is being supplied to the wellknown heavy haulage concern, E. W. Rudd, Ltd., of Stepney,' London, 414, and another 40-ton outfit is being 'delivered to the order of Currie and Co. (Newcastle), Ltd„ of Newcastle uponTyne: In the case of the machine bound for Newcastle, an additional straightframe contractor's carrier for 17-ton loads IS being sup

plied, together with , a. bogie which may be used to ,support the forward end Df 'the 40-ton carrier unit when used as a trailer. The 10,ton outfits have now passed their road tests, in the 2ourse of which it has been found possible to start from rest with a full 40-ton pay-load on one in eight.

c32 + The power unit employed is the well-known Scammell four-cylindered engine which has 'an R.A.C. rating of 40 h.p. and develops upproximately 80 b.h.p. at 1,800 r.p.m.; the bore is 5 ins, and the stroke 51 ins., the capacity being 7,078 c.c. As is well known, a meticulously graduated Simms automatic ignition-advance de vice is fitted to this engine.

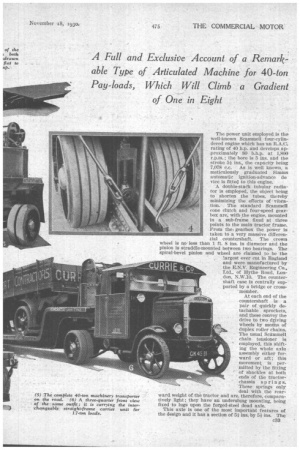

A double-staek tubular radiator is employed, the object being to shorten the tubes, thereby minimizing the effects of vibration. The standard Scammell cone clutch and four-speed gearbox are, with the engine, mounted in a sub-frame fixed at three points to the main tractor frame. From the gearbox the power is taken to a very massive differential countershaft. The crown wheel is no less than 1 ft. 8 ins, in diameter and the pinion is straddle-mounted between two bearings. The spiral-bevel pinion and wheel are claimed to be the largest ever cut in England and were manufactured by the E.N.V. Engineering Co., Ltd., of Hythe Road, London, N.W.10. The countershaft case is centrally supported by a bridge or cross. member.

At each end of the countershaft is a pair of -quickly detachable sprockets, and these convey the drive to two driving wheels by means of duplex roller chains. The usual Scammell chain tensioner is employed, this shifting the whole axle assembly either forward or aft; this movement is permitted by the fitting of shackles at both ends of the tractorchassis spring s. These springs only

deal with the rearward weight of the tractor and are, therefore, comparatively light ; they have an underslung mounting, being fixed to lugs upon the forged-steel dead axle.

This axle is one of the most important features of the design and it has a section of 51 ins. by 51 ins. The c33

driving wheels as well as all the other road wheels have Timken roller bearings. For journeys with full load, 12-tooth sprockets are fitted to the differential countershaft, these giving a speed of about 9 m.p.h. For lighter and faster work, 22-tooth sprockets can be fitted, these eying approximately 22 m.p.h. The difference in chain length when the sprockets are changed is effected by means of detachable links.

The bevel drive to the countershaft has a ratio Of 4.66 to 1, and the 12-tooth sprocket, with 52-tooth driven sprocket, further reduces the gearing in the ratio of 4.33 to 1. Multiplying bygearbox ratios the following overall ratios are obtained :—Forward, 20.18, 3522, 54.48 and 102.51 to 1; reverse, 130.25 to 1.

The forged-steel dead axle has on its upper surface saddles to which are bolted another pair of extremely heavy semi-elliptic springs which support the underplate of the turntable; a very rigid sub-frame is interposed between the turntable and these springs, provision being made at the front ends for the sliding of the spring leaves under flexion, which is indispensable.

The Reinforced Turntable.

The lower half of the turntable is a dished pressing made from *An. steel plate, the outside diameter being 3 ft. 5 ins. It is reinforced by a flat plate to which it is welded in two circles. The outer portion of the turntable merely acts as a steady, and the centre ring which takes the load has an external diameter of 151 ins, and an internal diameter of 111 ins.; it is lined with a self-lubricating impregnated cotton fabric.

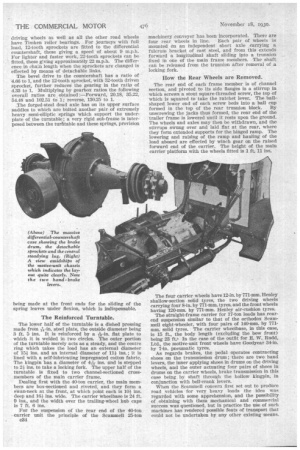

The kingpin has a diameter of ins, and is stepped to 21 ins, to take a locking fork. The upper half of the turntable is fixed to two channel-sectioned crossmembers of the main carrier frame.

Dealing first with the 40-ton carrier, the main members are box-sectioned and riveted, and they form a swan-neck at the front, at which point each is 101 ins. deep and 161 ins. wide. The carrier wheelbase is 24 ft. 9 ins., and the width over the trailing-wheel hub caps is 7 ft. 6 ins.

For the suspension of the rear end of the 90-ton carrier unit the principle of the Scammell 25-ton c34 machinery conveyer has been incorporated. There are four rear wheels in line. Each pair of wheels is mounted an an intdependent short axle carrying a fulcrum bracket of cast steel, and from this extends forward a longitudinal shaft sliding into a trunnion fixed in one of the main frame members. The shaft can be released from the trunnion after removal of a locking fork.

How the Rear Wheels are Removed.

The rear end of each frame member is of channel section, and pivoted to its side flanges is a stirrup in which screws a stout square-threaded screw, the top of which is squared to take the ratchet lever. The ballshaped lower end of each screw beds into a ball cup formed in the top of the rear trunnion block. By unscrewing the jacks thus formed, the rear end of the trailer frame is lowered until it rests upon the ground. The wheels and axles may then be withdrawn, and the stirrups swung over and laid flat at the rear, where they form extended supports for the hinged ramp. The lowering and raising of the ramp and hauling of the load aboard are effected by winch gear on the raised forward end of the carrier. The height of the main carrier platform with the wheels fitted is 1 ft. 11 ins.

The four carrier wheels have 12-in. by 771-mm. Henley shallow-section solid tyres, the two driving wheels carrying four 8-in. by 771-mm. tyres, and the front wheels having 120-mm. by 771-mm. Henley air-cushion tyres. The straight-frame carrier for 17-ton loads has rearend suspension similar to that of the orthodox Scammell eight-wheeler, with four pairs of 140-mm. by 771mm. solid tyres. The carrier wheelbase, in this case, is 15 ft., the body length (excluding the bow front) being 23 ft...* In the case of the outfit for E. W. Rudd, Ltd., the motive-unit front wheels have Goodyear 34-in. by 7-in, pneumatic tyres.

As regards brakes, the pedal operates contracting shoes on the transmission drum; there are two hand levers, the inner applying shoes in drums on the driving wheels, and the outer actuating four pairs of shoes in drums on the carrier wheels, brake transmission in this case being by shaft through the hollow kingpin, in conjunction with belr-crank levers.

When the Scammell concern first set out to produce road vehicles for very heavy loads the idea was regarded with some apprehension, and the possibility of obtaining with them mechanical and commercial success was questioned, but in practice the use of such machines has rendered possible feats of transport that could not be undertaken by any other existing means.